Process and device for rectifying and separating stable isotope 13C at low temperature by adopting CO

A stable isotope, low temperature rectification technology, applied in the separation of different isotopic elements, separation methods, dispersed particle separation, etc., can solve the problems of difficult isotope products, high consumption of cold energy, high production cost, and overcome the slow reaction speed, The effect of avoiding equipment failure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

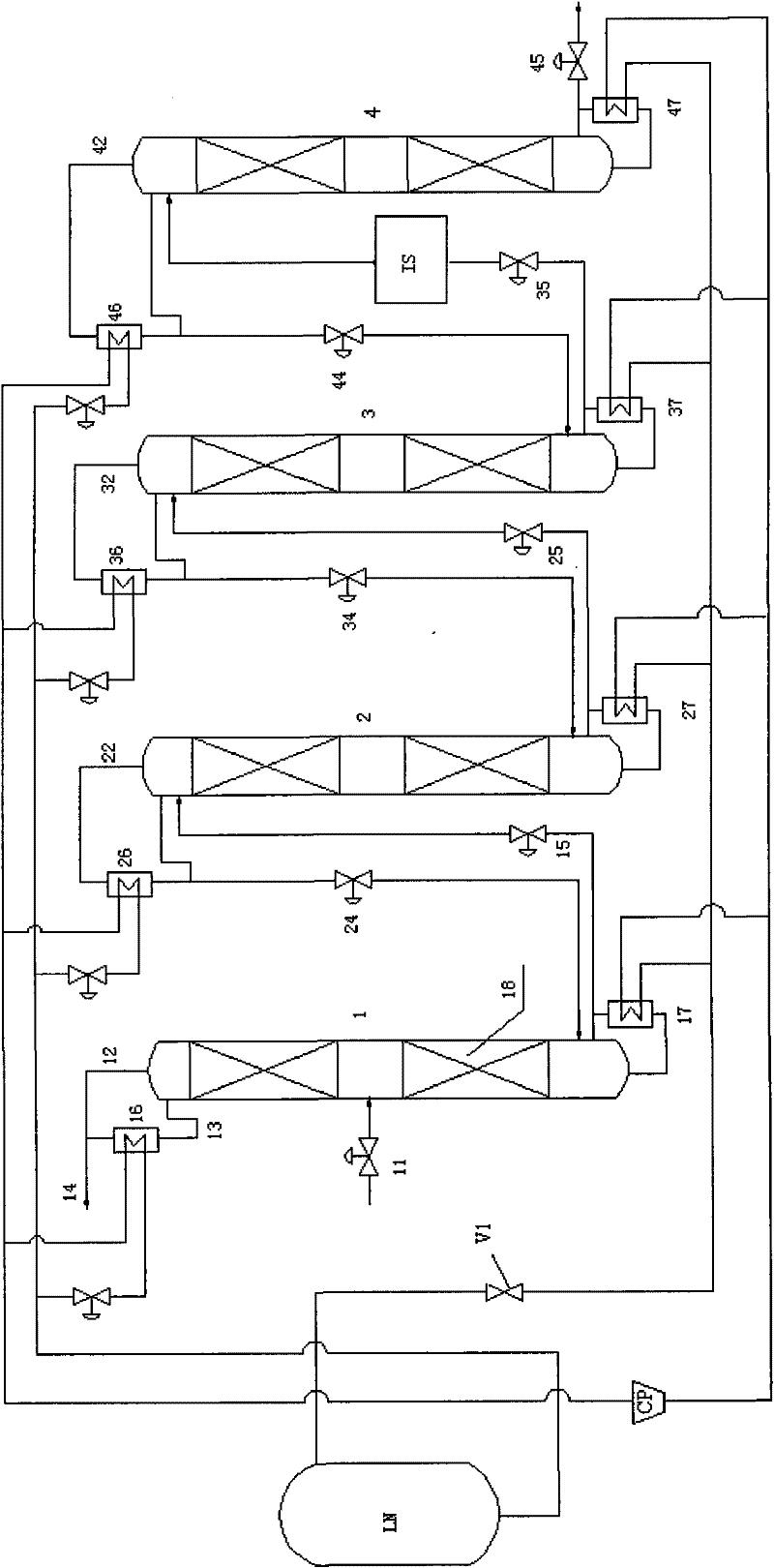

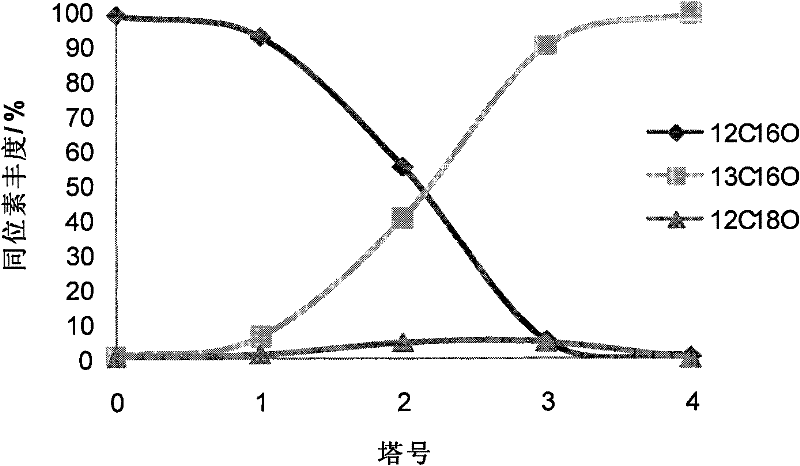

[0039] Four low-temperature rectification towers are used as the first stage rectification tower 1, the second stage rectification tower 2, the third stage rectification tower 3, and the fourth stage rectification tower 4 to form a horizontal four-stage cascade production 13 C, such as figure 2 As shown, the rectification tower is 30 meters high, and the tower diameters are 390, 200, 90, and 45 mm respectively. The tower is filled with stainless steel wire mesh corrugated structured packing 18, and the production capacity is 99% of the annual output of 100 kg. 13 C, see Table 1 for specific parameters. The high-purity raw material CO is fed from the feed port through the regulating valve 11, the flow rate is 6366 mol / day, the gas phase in the tower flows to the top condenser 16, and the condensate 13 flows back into the first-stage rectifying tower 1 as a spray liquid; another part of the tower top gas 14 is discharged and sold as a chemical raw material, and the liquid CO i...

Embodiment 2

[0045] Four low-temperature rectification towers are used as the first stage rectification tower 1, the second stage rectification tower 2, the third stage rectification tower 3, and the fourth stage rectification tower 4 to form a horizontal four-stage cascade production 13 C, such as Figure 5 As shown, the rectification tower is 30 meters high, and the tower diameters are 390, 200, 90, and 45 mm in turn. The production capacity is 99% of the annual output of 100 kg 13 c. The high-purity raw material CO is fed from the feed port through the regulating valve 11, and the flow rate is 6366 mol / day. The gas phase in the tower flows to the top condenser 16, and the condensate 13 flows back into the tower as a spray liquid; the other part of the top gas 14 is discharged and sold as chemical raw materials. The liquid CO in the tower flows from the packing surface to the tower bottom 17 and is heated and vaporized. Part of it flows upward in the packing space in the tower and exc...

Embodiment 3

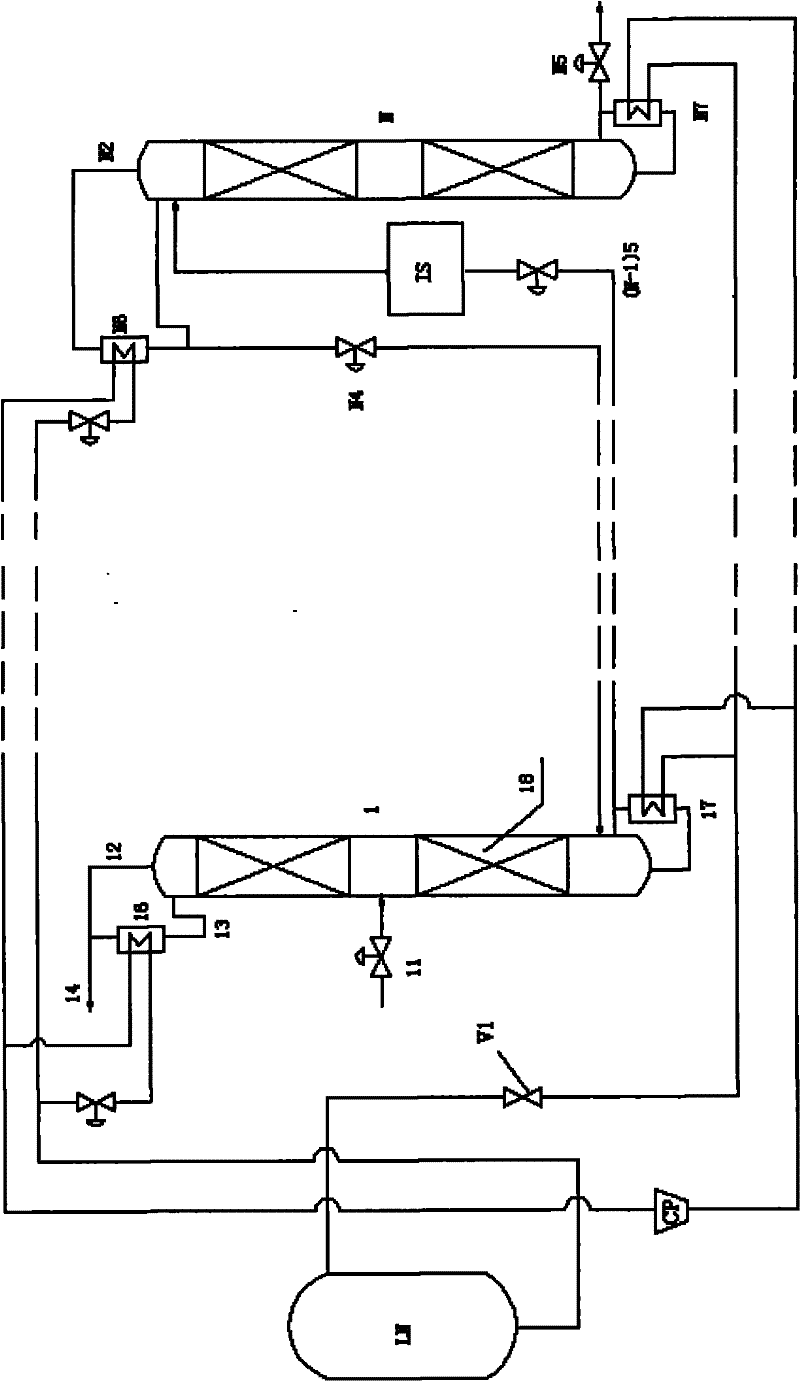

[0048] A process and device for separating stable isotope 13C by low-temperature rectification of CO, the structure of which is as follows figure 1 As shown, the separation system is cryogenic rectification tower 1, cryogenic rectification tower N, structured packing 18, condenser 16, condenser N6, reboiler 12, reboiler N2, isotope scrambler IS, liquid nitrogen circulation system The cascading towers formed, the cascading method adopts the horizontal multi-tower cascading without power transmission, which is realized in the isotope scrambler 13 C 16 O and 12 C 18 O isotope conversion, rectification to get 99% 13 C product.

[0049] There is no power transmission equipment between the cascading towers, the gas phase at the bottom of the former tower flows to the top of the latter tower under the push of the pressure difference, and is used as the spray liquid of the latter tower after being condensed, and the CO vapor at the top of the latter tower is condensed Under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com