Meat quality flavor modifying agent for grass carp or carp and preparation method thereof

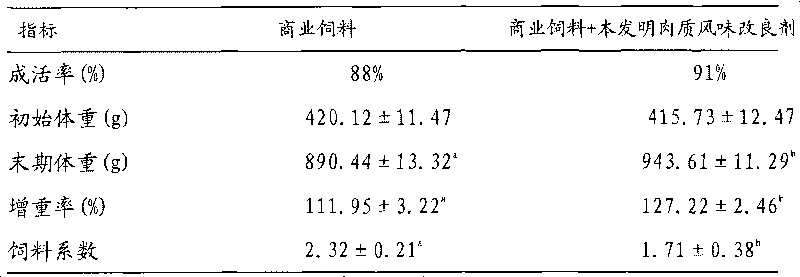

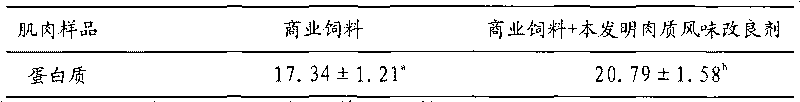

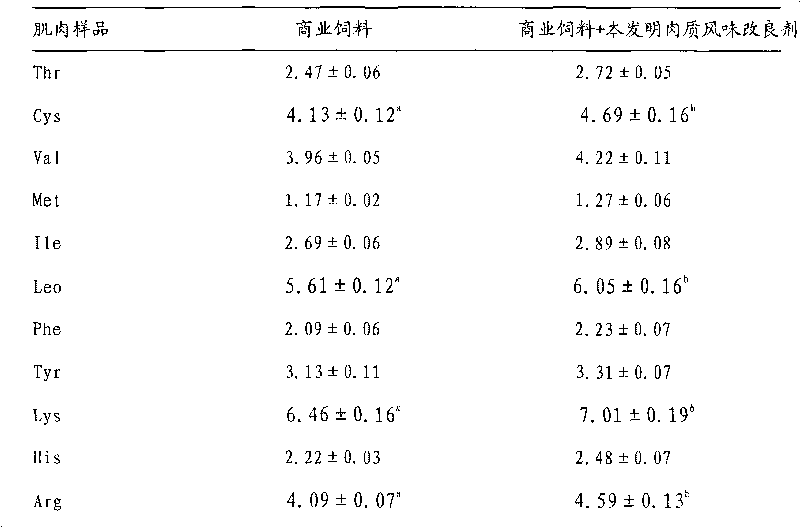

A meat flavor and improver technology, applied in application, animal feed, animal feed, etc., can solve the problems of essential amino acid ratio, low essential amino acid index, low protein content in bait, amino acid imbalance, etc., to improve meat quality and body color. , Increase muscle taste and density, reduce the effect of intermuscular fat and abdominal fat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The meat quality flavor improver of the present invention is mainly composed of seaweed extract, combination of inosinic acid and guanylic acid, carnitine, glycine, alanine and zeolite powder. The weight of the meat flavor improver accounts for 1% of the grass carp or carp feed weight, and is made of the following raw material combination by weight ratio, and the component content per kilogram of the improver is: seaweed extract 30g, inosinic acid and avian Glucoside combination 10g, carnitine 20g, glycine 15g, alanine 10g, and the rest is zeolite powder. In the combination of inosinic acid and guanylic acid, the weight ratio of inosinic acid and guanylic acid is 1:1.

[0017] For the seaweed extract, the fresh seaweed is washed to remove impurities and chopped, the seaweed is extracted by boiling, and the extracted material is placed in a stirring reactor, the temperature is controlled at 45°C, and the pH value is controlled at 6-7. Stirring speed is 800rpm, then add ...

Embodiment 2

[0020] The meat quality flavor improver of the present invention is mainly composed of seaweed extract, combination of inosinic acid and guanylic acid, carnitine, glycine, alanine and zeolite powder. The weight of the meat flavor improver accounts for 1% of the weight of the grass carp or carp feed, and is made of the following raw materials in the weight ratio. The component content per kilogram of the improver is: seaweed extract 35g, inosinic acid and avian Glucoside combination 15g, carnitine 25g, glycine 20g, alanine 15g, and the rest is zeolite powder. In the combination of inosinic acid and guanylic acid, the weight ratio of inosinic acid and guanylic acid is 1:1.

[0021] For the seaweed extract, the fresh seaweed is washed to remove impurities and chopped, the seaweed is extracted by boiling, and the extracted material is placed in a stirring reactor, the temperature is controlled at 50°C, and the pH value is controlled at 7-8. Stirring speed is 1000rpm, then add abs...

Embodiment 3

[0023] The meat quality flavor improver of the present invention is mainly composed of seaweed extract, combination of inosinic acid and guanylic acid, carnitine, glycine, alanine and zeolite powder. The weight of the meat flavor improving agent accounts for 2% of the feed weight of grass carp or carp, and is made of the following raw material combination by weight ratio, and the component content of every kilogram of improving agent is: seaweed extract 50g, inosinic acid and avian Glucoside combination 20g, carnitine 30g, glycine 30g, alanine 20g, the rest is zeolite powder. In the combination of inosinic acid and guanylic acid, the weight ratio of inosinic acid and guanylic acid is 1:1.

[0024] For the seaweed extract, the fresh seaweed is washed to remove impurities and chopped, the seaweed is extracted by boiling, and the extracted material is placed in a stirring reactor, the temperature is controlled at 65°C, and the pH value is controlled at 7-8. Stirring speed is 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com