Interphase electromagnetic decoupling cylindrical permanent magnet linear synchronous motor

A permanent magnet synchronous linear and cylindrical technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problem of large iron loss of the stator, and achieve the effect of improving efficiency, shortening magnetic circuit, and reducing eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

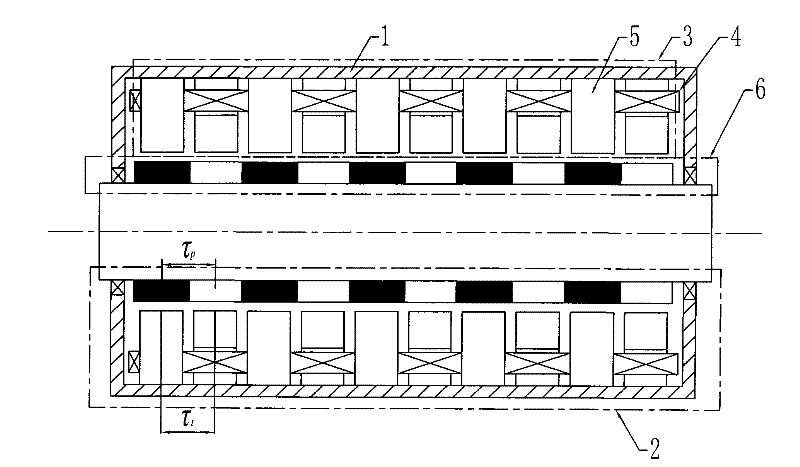

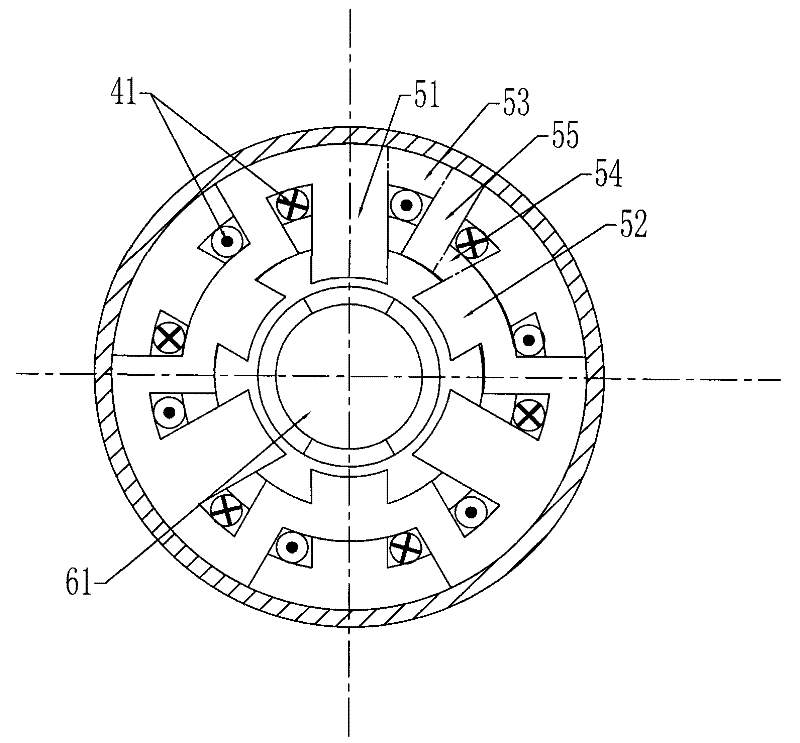

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with 12 To illustrate this embodiment, it is composed of a casing 1, a primary and a secondary 6; the secondary 6 is composed of a permanent magnet array and a shaft cylinder 61; the primary is composed of several phase units 2; each phase unit 2 is composed of several phase units Iron core 3 and phase winding 4; each phase unit iron core 3 is composed of 2k iron core units 5;

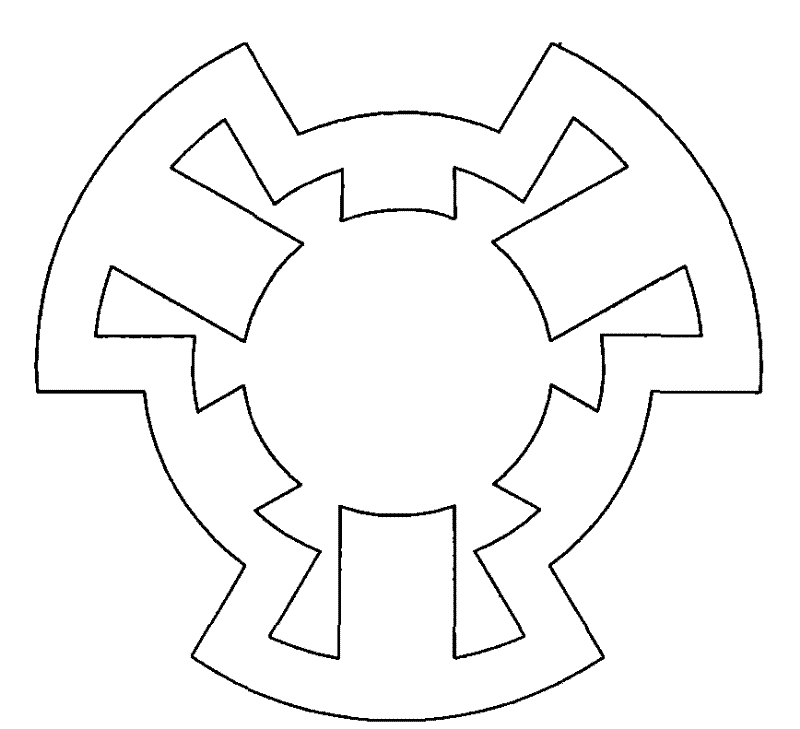

[0008] Each core unit 5 is made up of 2n teeth, 2n outer peripheral yoke segments 53, 2n inner peripheral yoke segments 54 and 2n radial yoke segments 55; 2n teeth are composed of n long teeth 51 and n short teeth teeth 52, n long teeth 51 and n short teeth 52 are arranged at equiangular intervals along the circumferential direction, and each long tooth 51 and each short tooth 52 are connected in turn with an outer peripheral yoke segment 53, a radial A yoke segment 55 and an inner peripheral yoke segment...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the shaft barrel 61 is cylindrical or cylindrical; the shaft barrel 61 is made of magnetically conductive or non-magnetically conductive material. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 5 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the permanent magnet array is composed of tile-shaped permanent magnets 62, and the magnetization direction of the tile-shaped permanent magnets 62 is radial magnetization, and the plurality of tiles Shaped permanent magnets 62 are adjacently arranged to form a permanent magnet circle along the circumferential direction, and 2q permanent magnet circles are arranged adjacent to each other along the axial direction, and the magnetization direction of every adjacent two tile-shaped permanent magnets 62 is opposite. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com