Method of determining mesh data and method of correcting model data

A technology of model data and calibration model, which is applied in the direction of electrical digital data processing, special data processing applications, comprehensive factory control, etc., can solve the problems of complex smoothing processing, time-consuming, too much load on the computer, etc., and achieve reliable automatic identification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

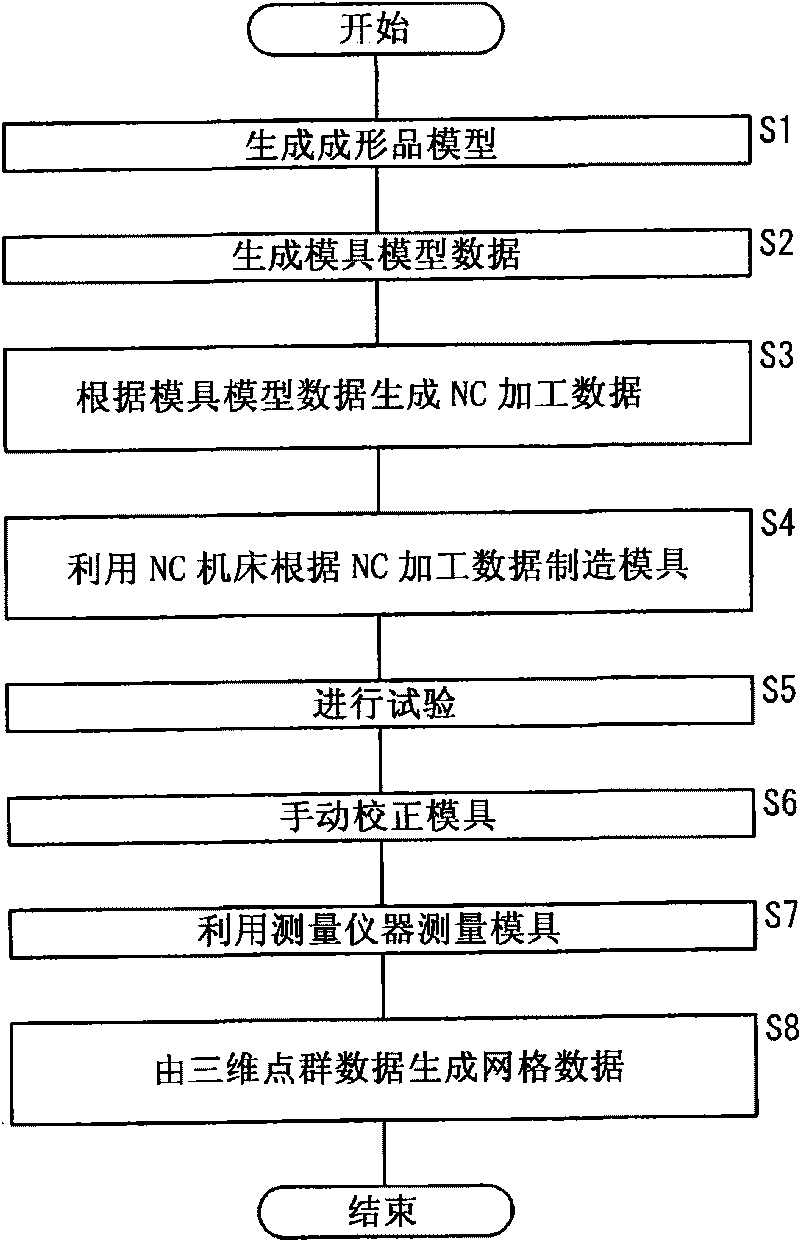

[0057] Refer to the following Figure 1-10 A method for determining grid data according to an embodiment of the present invention is described.

[0058] First, the following reference figure 1 The previous process performed before the method of determining grid data according to the present embodiment will be described.

[0059] exist figure 1 In step S1 shown in , a molded article to be obtained is designed, and data of a molded article model is generated.

[0060] In step S2, the data of the die model is generated on the CAD system based on the data of the molded product model.

[0061] In step S3, NC (numerical control) data for controlling an NC (numerical control) machine tool is generated from the mold model data.

[0062] In step S4, a mold as a test mold is produced by an NC machine tool based on the NC data.

[0063] In step S5, the molded article serving as the test article is pressed using the produced test mold.

[0064] In step S6, the test article and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com