Method for detecting leakage of spacecraft cabin by differential pressure

A differential pressure leak detection and spacecraft technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc., to achieve the effect of avoiding over-range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

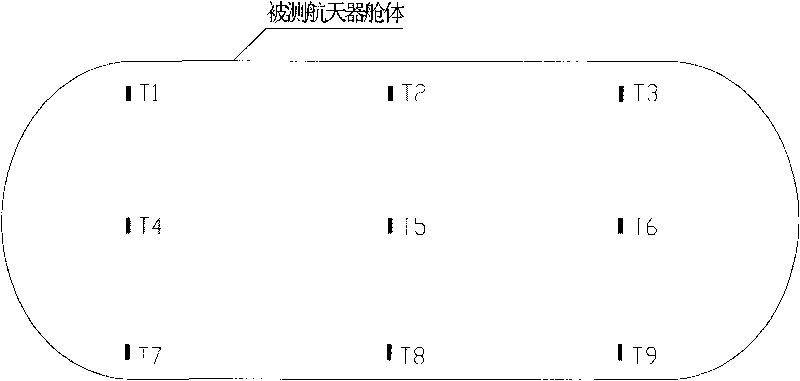

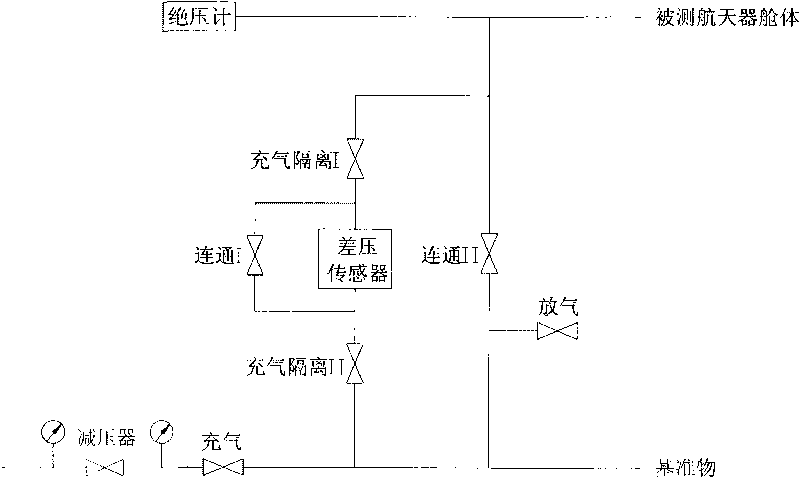

[0023] The principle of the present invention is as follows: the reference object used in the leak detection process has been proved to be leak-proof with other leak detection methods such as helium mass spectrometry, and in the inflation and balancing steps, since the reference object and the spacecraft cabin body to be tested are connected , so the differential pressure sensor reads zero. At the beginning of the test procedure, the reference object is isolated from the cabin of the spacecraft under test. At this time, if the cabin of the spacecraft under test leaks, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com