Low-speed bidirectional regulating hydraulic buffer

A hydraulic buffer, two-way adjustment technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of single installation method, unadjustable buffer speed, bearing capacity, and poor versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

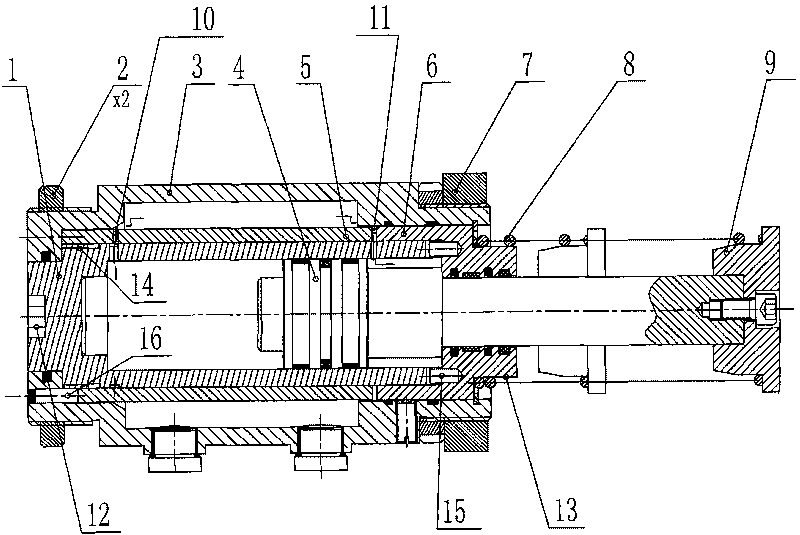

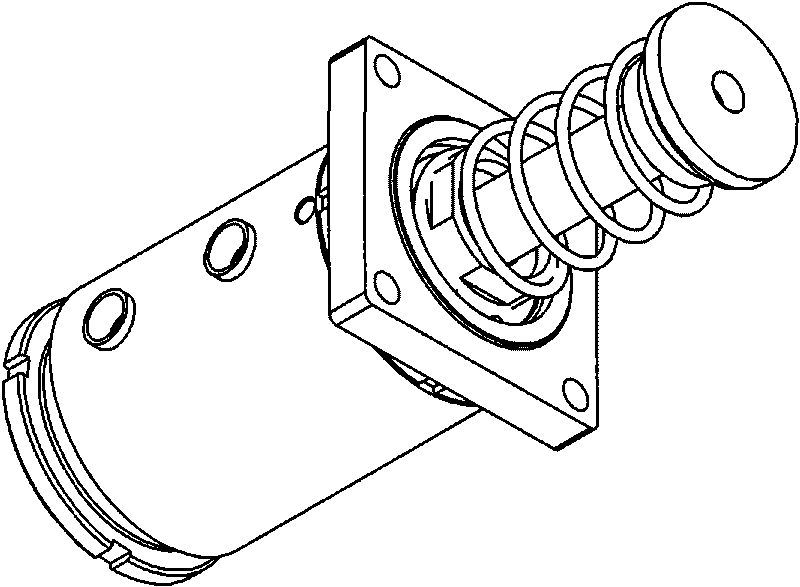

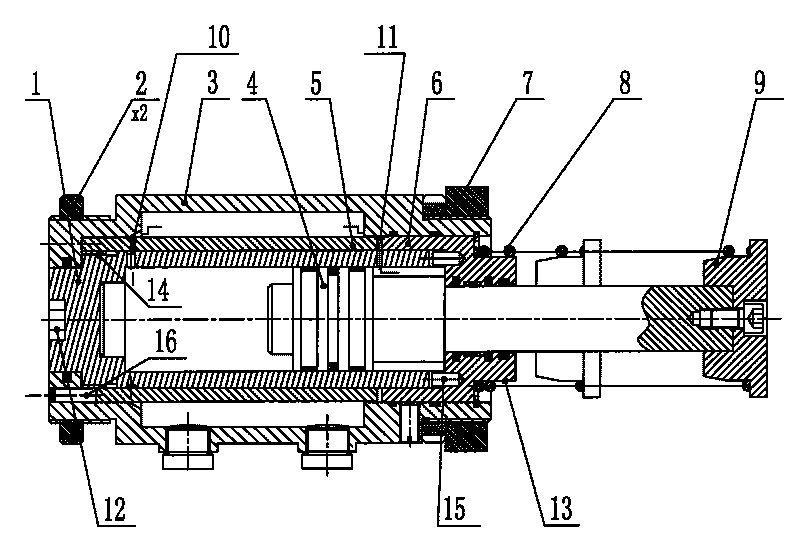

[0009] as attached figure 1 And attached figure 2 As shown, the present invention includes a housing 3, a cylinder 1 is arranged in the housing 3, and one end of the piston rod 4 is located in the cylinder 1. It is characterized in that: the cylinder 1 and the end cover 6 are connected by a linkage pin 15, and the cylinder A guide pin 16 is provided between the body 1 and the housing 3, a spring 8 is provided between the other end of the piston rod 4 and the contact 9, damping holes 10 and 11 are respectively provided at both ends of the sliding sleeve 5 in the housing 3, and The left end of the cylinder body 1 and the right end of the end cover 6 are provided with adjusting points 12 and 13 respectively, and the sliding sleeve 5 cooperates with the adjusting screw rod 14 . The housing 3 is provided with a collar 2 and a mounting flange 7 .

[0010] The working principle of the present invention is as follows:

[0011] The contact 9 pushes the piston rod 4 to move from rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com