Gas-gas nozzle with constriction section

A shrinking section and gas nozzle technology, which is applied in the field of liquid rocket engine nozzles, can solve the problems of small pressure drop of oxidant nozzles and affecting engine performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention proposes a gas-gas nozzle with a constricted section for the first time, which can prevent the pressure fluctuation of the combustion chamber from being transmitted into the head cavity, and make the propellant achieve high combustion efficiency. The gas-gas nozzle with a contraction section and its design method are provided, which can ensure efficient and stable combustion of the propellant, and the design method is simple and effective.

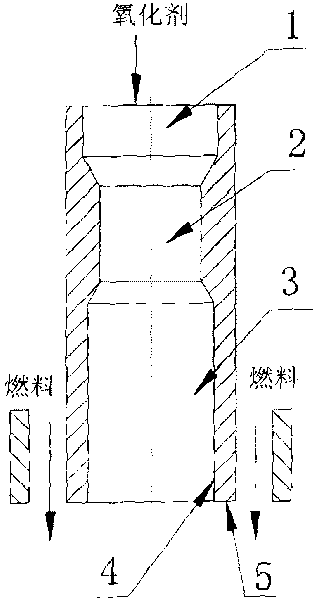

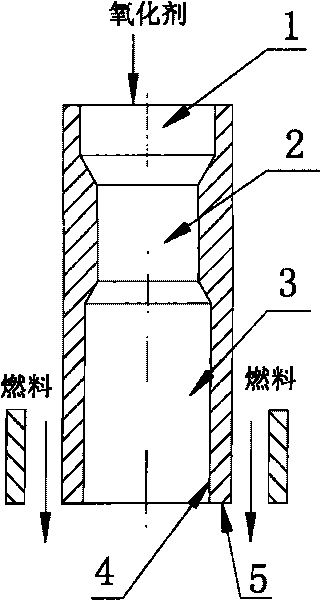

[0013] Such as figure 1 The shown gas-gas nozzle with converging section includes nozzle inlet short (1), converging section (2), outlet section (3) and fuel nozzle (6). The inlet section of the nozzle is cylindrical, and its area is 1.5 to 2 times the area of the contracting section; the length of the inlet section is 5 to 10 mm; the contracting section and the inlet section adopt a tapered transition, and the angle is 90 to 120 degrees. Through the selected pressure drop and flow coefficient of the oxidant nozzle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com