Deep hole arranging method in mining

An arrangement method and deep hole technology, which can be used in surface mining, underground mining, special mining, etc., can solve the problems of uneven ore particle size distribution, unfavorable ore flow, less blast hole collapse, etc., and improve the composition of particle size distribution. The effect of improving the flow of ore and rock, improving the conditions of entry and exit, and reducing the number of blast holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

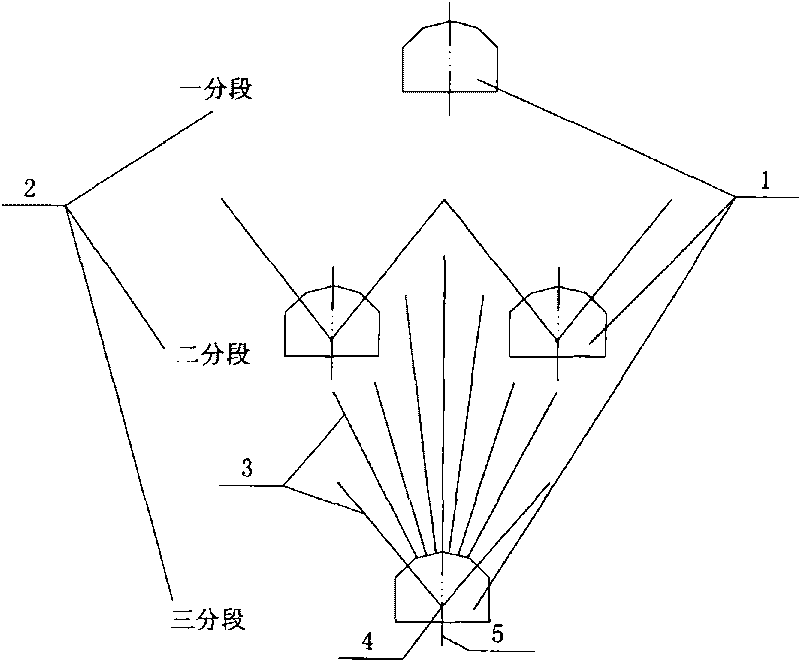

[0025] Example 1: In a large-scale underground production mine, the ore body is concentrated and thick, with a strike length of 1370m, a width of 824m, and an average thickness of 134m. It adopts the joint development of shafts and slopes, and the mining method of segmental caving without pillars. The structural parameters of the stope It is 15m×15m, and the access section is 5.0m×3.8m. The mining medium and deep hole parameters are: the diameter of the blast hole is 78mm, the row spacing is 1.6m, and the hole bottom distance is 2.0-2.5m. Use SimbaH1354 full hydraulic rock drilling rig with cop1838 rock drill for mining medium and deep hole operations. The big arm of the rock drilling rig has the function of moving left and right. The rock drill is fixed on the propulsion beam, and the propulsion beam rotates around the rotary axis to adjust the blast hole. construction angle. The traditional method is: determine the center line of the roadway according to the cross-sectional ...

Embodiment 2

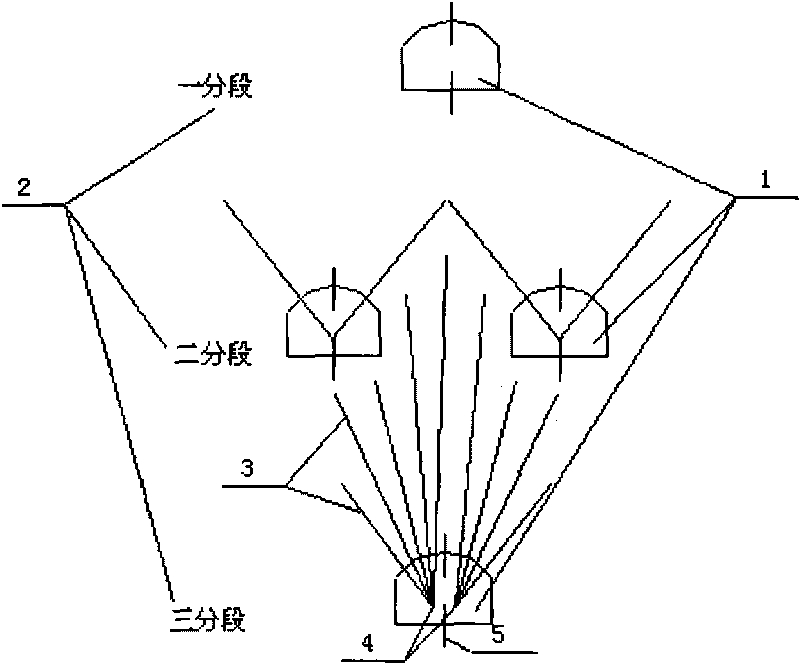

[0026] Example 2: The northern ore body of Meishan Iron Mine is a branch of the main ore body. The ore body elevation is -89m. The mining method of ramp development and segmental caving without pillars is adopted. The stope structure parameter is 12m× 10m, the approach section is 4.2m×3.2m, and the mining medium and deep hole parameters are: the blast hole diameter is φ60mm, the row spacing is 1.8m, and the hole bottom distance is 1.6-2.0m. The CTC-141 pneumatic rock drilling rig is equipped with YG90 rock drilling machine for mining medium and deep hole operations. There are upper and lower rotary shafts (namely: main rotary shaft and secondary rotary shaft) on the big arm of the rock drilling rig, and the push beam Fixed on the upper secondary rotary shaft, the upper and lower rotary shafts can adjust the construction angle of the blast hole. The traditional method is: determine the center line of the roadway according to the cross-sectional diagram of the mining approach, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com