Spray coloring stack dying process for cotton woven fabrics

A process and grey fabric technology, which is applied in the field of spray color stacking dyeing process for cotton fabrics, and can solve the problems of permanent pad printing, dyeing color difference, and inability to guarantee uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

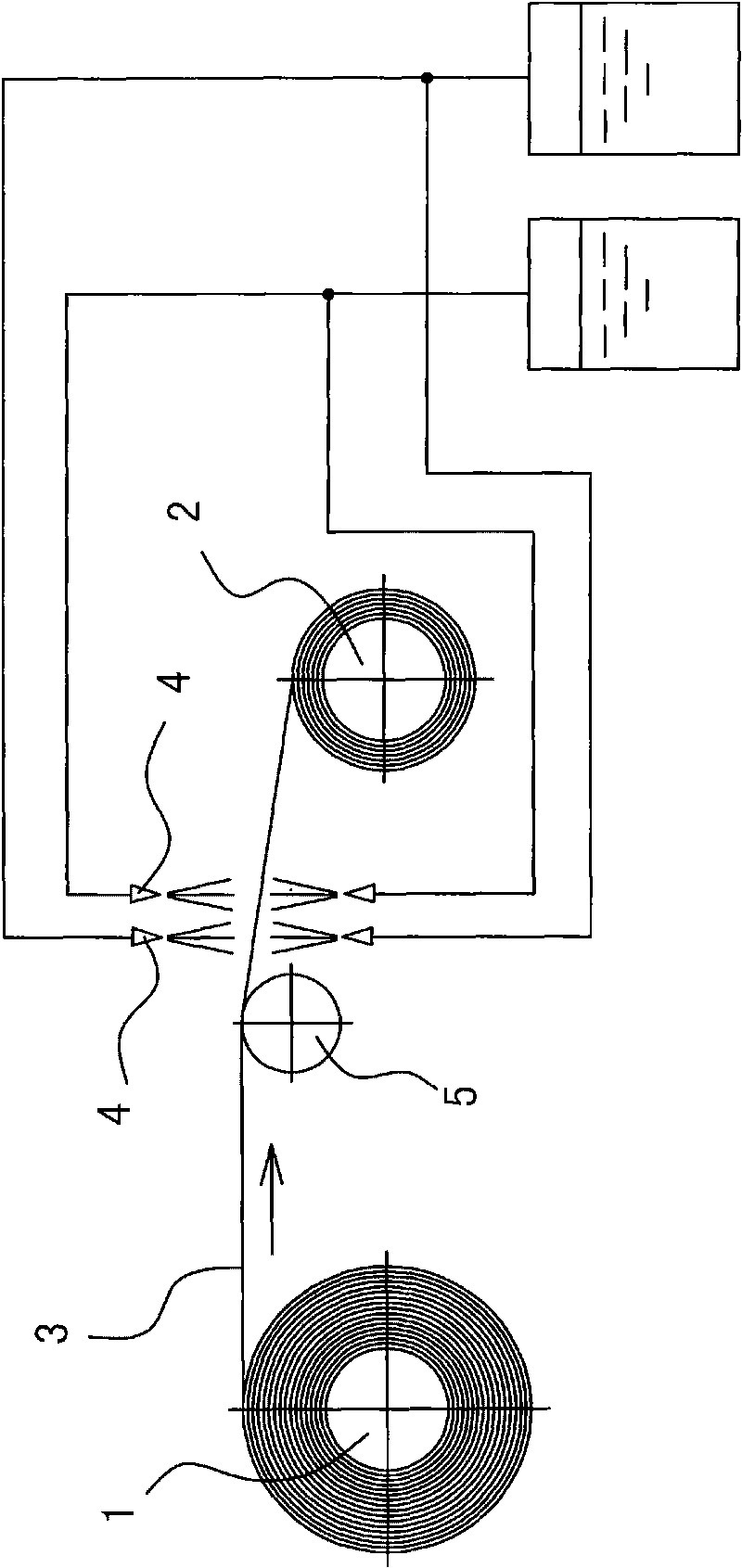

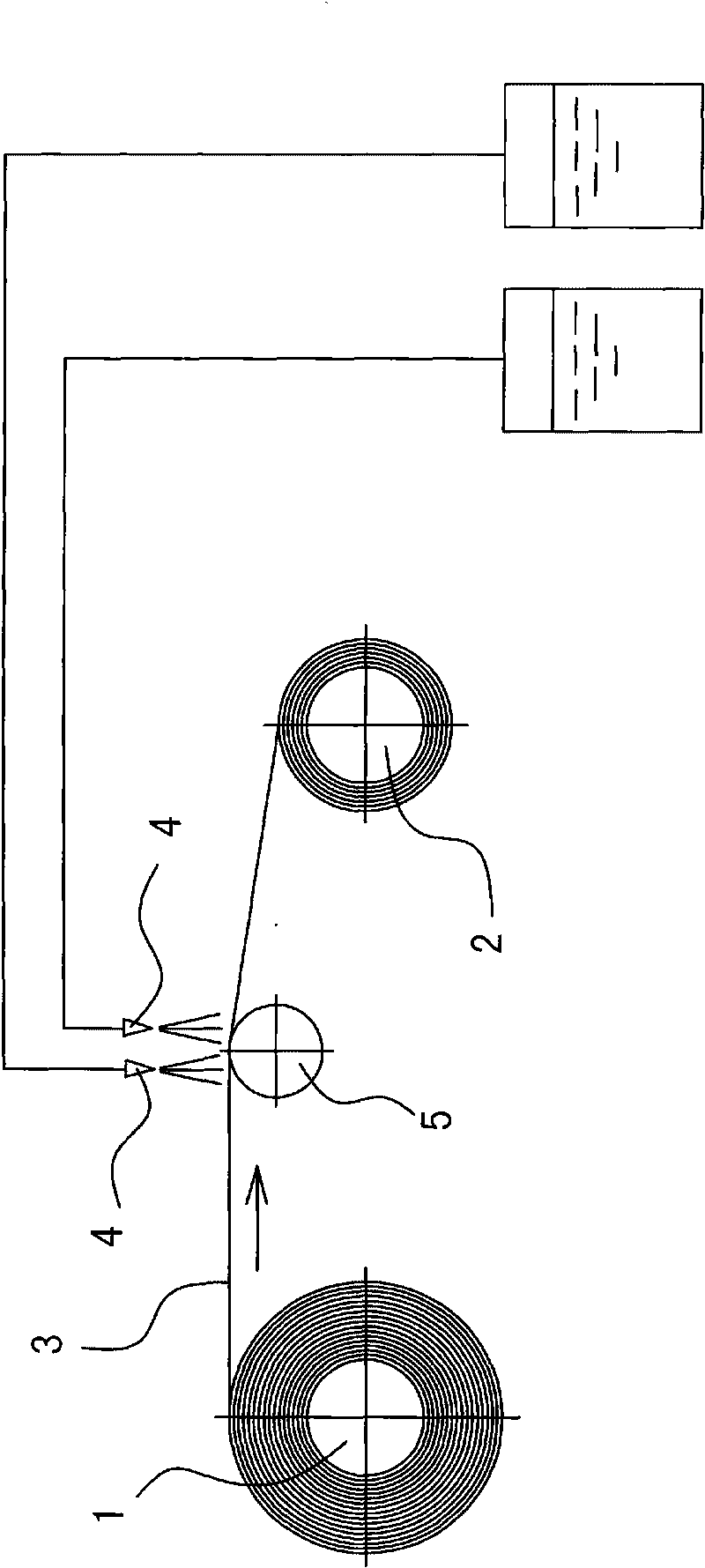

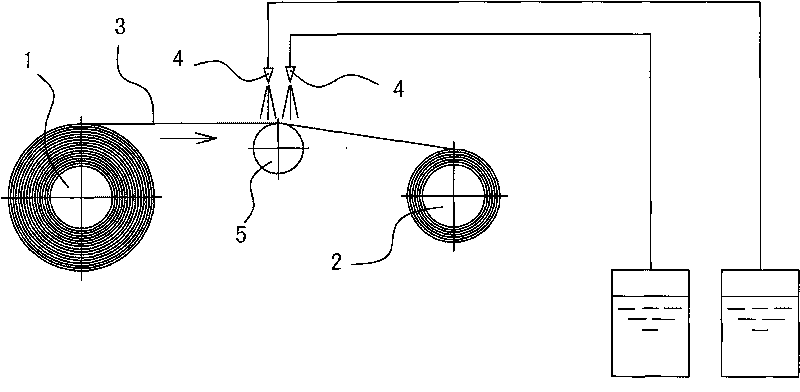

Image

Examples

Embodiment 1

[0060] Embodiment 1: A kind of cotton fabric spray color to stack dyeing process

[0061] Get 32 double-yarn double-threaded cylindrical jerseys, and use reactive dyes, dyeing accelerators and alkaline agents to dye the gray cloth with army green. Wherein the active dyestuff is military green active dyestuff, the dyeing accelerator is sodium hydroxide, and the alkaline agent is sodium hydroxide. Prepare reactive dyes, dye accelerators and alkali agents into aqueous solutions before use. The ratio of the total weight of the fabric of the gray cloth to the total weight of the sprayed solution is controlled in the scope of 1: 1 to 1.5, and the total weight of the solution is the sum of the weights of the reactive dye aqueous solution, the dye accelerator aqueous solution and the alkaline agent aqueous solution, wherein the reactive dye aqueous solution The weight accounts for 60-70% of the total weight of the solution, the weight of the aqueous solution of the dyeing accelerat...

Embodiment 2

[0068] Embodiment 2: A kind of cotton fabric spray color to stack dyeing process

[0069]Take a piece of double-sided ribbed open-width cloth, and use reactive dyes and alkali agents to dye the gray cloth in large black. Among them, the reactive dye is selected from large black reactive dye, and the alkali agent is sodium hydroxide. Prepare reactive dyes and alkaline agents into aqueous solutions before use. The ratio of the total weight of the fabric of the gray cloth to the total weight of the sprayed solution is controlled in the scope of 1: 1~1.5, and the total weight of the solution is the sum of the weight of the reactive dye aqueous solution and the alkaline agent aqueous solution, wherein the weight of the reactive dye aqueous solution accounts for the total weight of the solution. 60% to 70% of the total weight of the solution, and the weight of the aqueous alkali solution accounts for 40% to 30% of the total weight of the solution.

[0070] Before dyeing, the gray ...

Embodiment 3

[0077] Embodiment 3: A kind of cotton fabric spray dyeing process of pile dyeing

[0078] Get 32 pieces of double-yarn double-threaded cylindrical jersey, and use reactive dyes and alkaline agents to dye the gray cloth with army green. Wherein reactive dyestuff is selected military green reactive dyestuff, and alkali agent adopts sodium hydroxide. Prepare reactive dyes and alkaline agents into aqueous solutions before use. The ratio of the total weight of the fabric of the gray cloth to the total weight of the sprayed solution is controlled in the scope of 1: 1~1.5, and the total weight of the solution is the sum of the weight of the reactive dye aqueous solution and the alkaline agent aqueous solution, wherein the weight of the reactive dye aqueous solution accounts for the total weight of the solution. 60% to 70% of the total weight of the solution, and the weight of the aqueous alkali solution accounts for 40% to 30% of the total weight of the solution.

[0079] Before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com