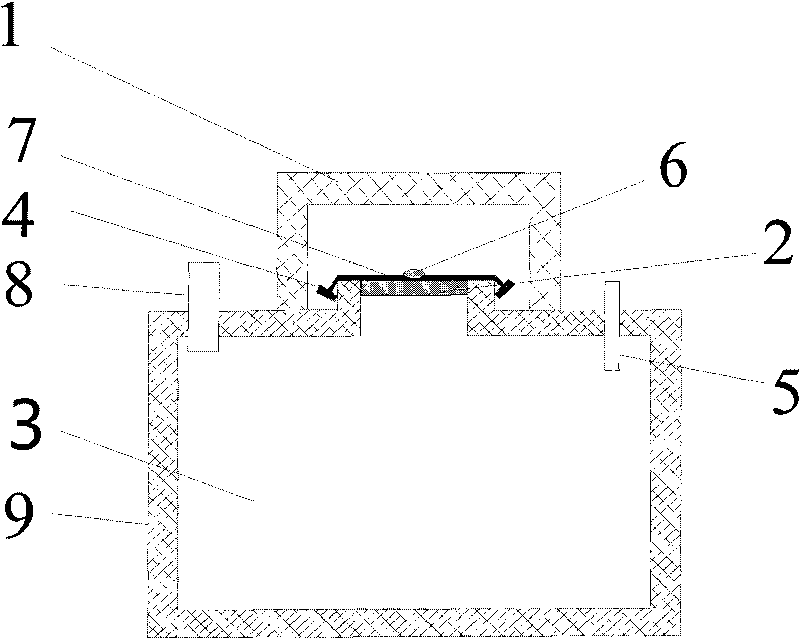

Device and method for testing fabric contact coldness

A test device and a technology of contact cold feeling, which is applied in the field of textile engineering, can solve the problems of expensive test equipment, high use and maintenance costs, and high technical requirements, and achieve the effects of low manufacturing cost, high precision, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

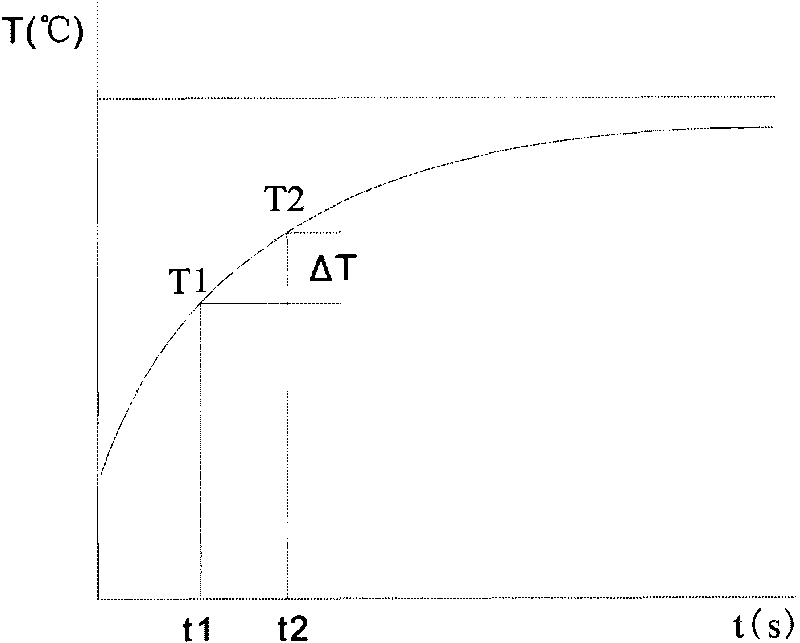

Method used

Image

Examples

specific Embodiment

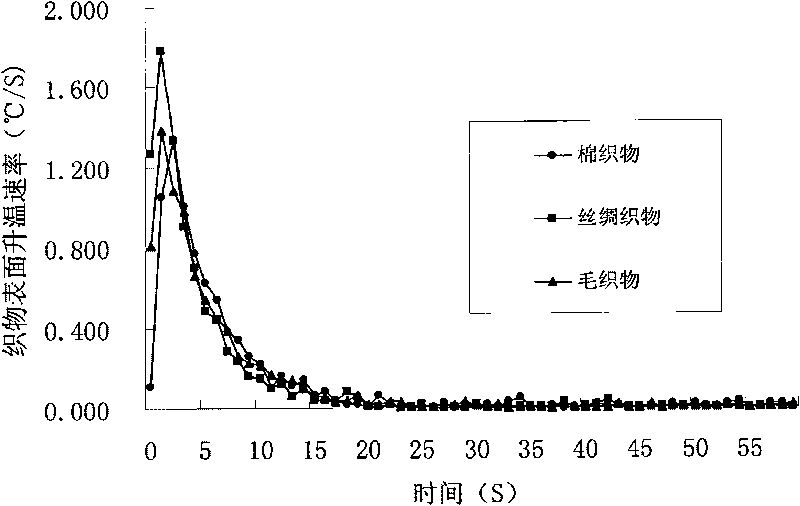

[0048] Use the above test methods to test the temperature of the surface of the three kinds of fabrics with time. The maximum value of the temperature rise rate of the fabric surface is obtained, and the cold feeling of the fabric is evaluated.

[0049] Table 1 The average value of the surface temperature of three kinds of fabrics per second (℃)

[0050] Table 1

[0051] time (seconds)

cotton fabric

woolen fabric

0

24.925

25.097

25.030

1

25.035

26.369

25.841

2

26.083

28.148

27.223

3

27.425

29.481

28.307

4

28.432

30.384

29.290

[0052] time (seconds)

cotton fabric

woolen fabric

5

29.203

31.085

29.947

6

29.825

31.563

30.484

7

30.366

32.005

30.927

8

30.742

32.286

31.309

9

31.085

32.518 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com