Method for detecting washing powder residue and washing machine

A technology for washing powder and washing machine, which is applied in the control device, washing device, measuring device and other directions of washing machine, can solve the problem of whether there is residual detection without washing powder, and achieve the effect of reducing washing time and reducing washing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

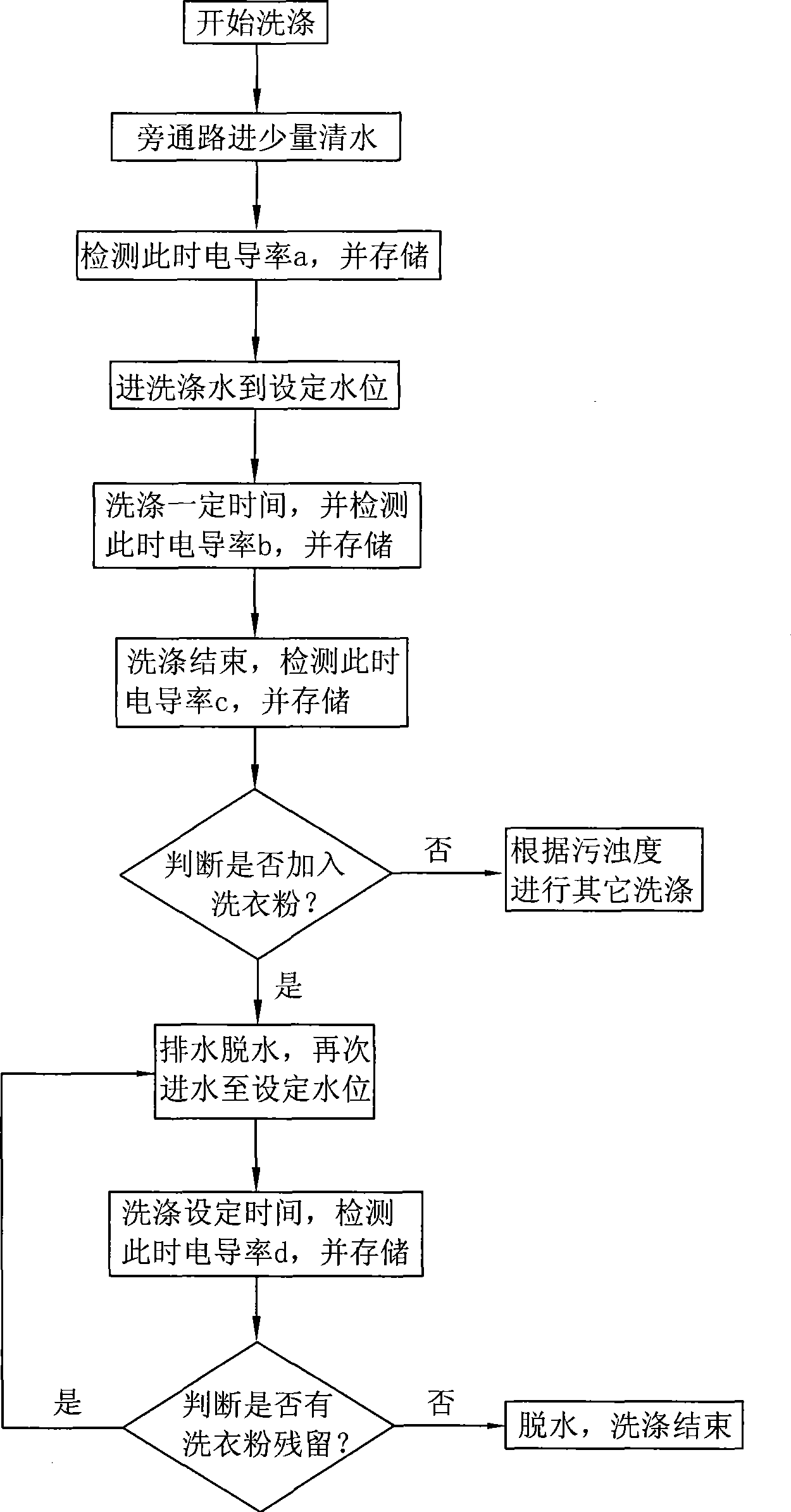

[0046] The washing machine starts washing, and the measured conductivity a is 100ppm, b is 2000ppm, and c is 2100ppm;

[0047] Then, because b-a=1900 ppm, it is judged that washing powder is added to the washing water.

[0048] After entering the first rinsing program, the measured conductivity d1 after washing is 1000 ppm. d1=1000ppm is less than c=2100ppm, and d1-a=900 is greater than 200, then add a rinse; re-determine the conductivity d2 to 500ppm, then d2-a=400, which is greater than 200, rinse again, and measure d3 again =200ppm, then d3-a=100 <200, the detected residual amount is less than the standard, after the rinsing is completed, the dehydration program is directly entered.

[0049] The invention judges whether the washing powder has residuals by comparing the conductivity of the washing water detected at different washing times, thereby adjusting the washing and rinsing times, reducing washing time, reducing washing costs, and bringing users a healthy washing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com