Pinhole-proof aqueous coating agent for powder-free PVC gloves and preparation method thereof

An anti-pinhole, water-based coating technology, applied to gloves, clothing, applications, etc., can solve the problems of potential contamination of the operated object, potential threat caused by the user, and reduced production efficiency, so as to avoid the reduction of production efficiency and significantly resist adhesion Function, good anti-pinhole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

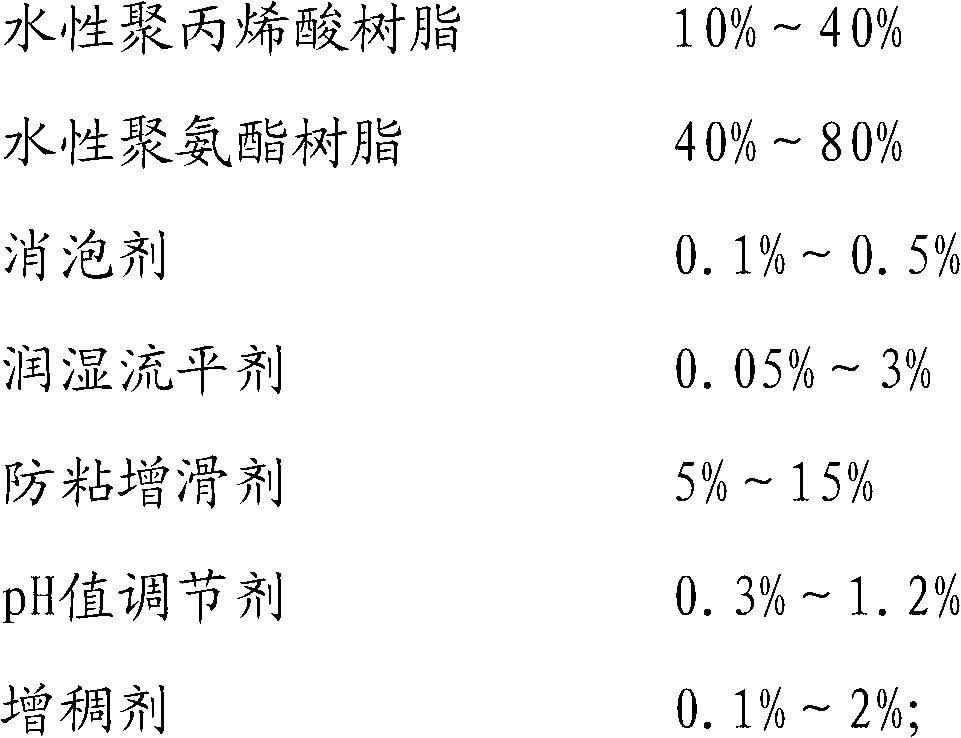

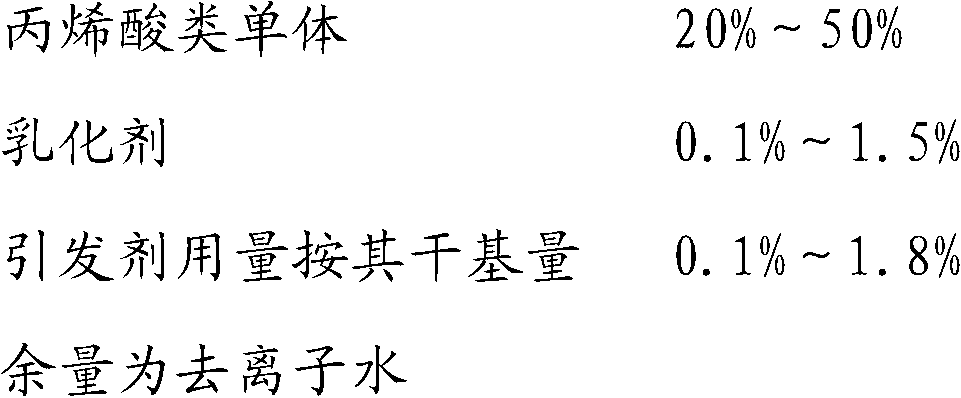

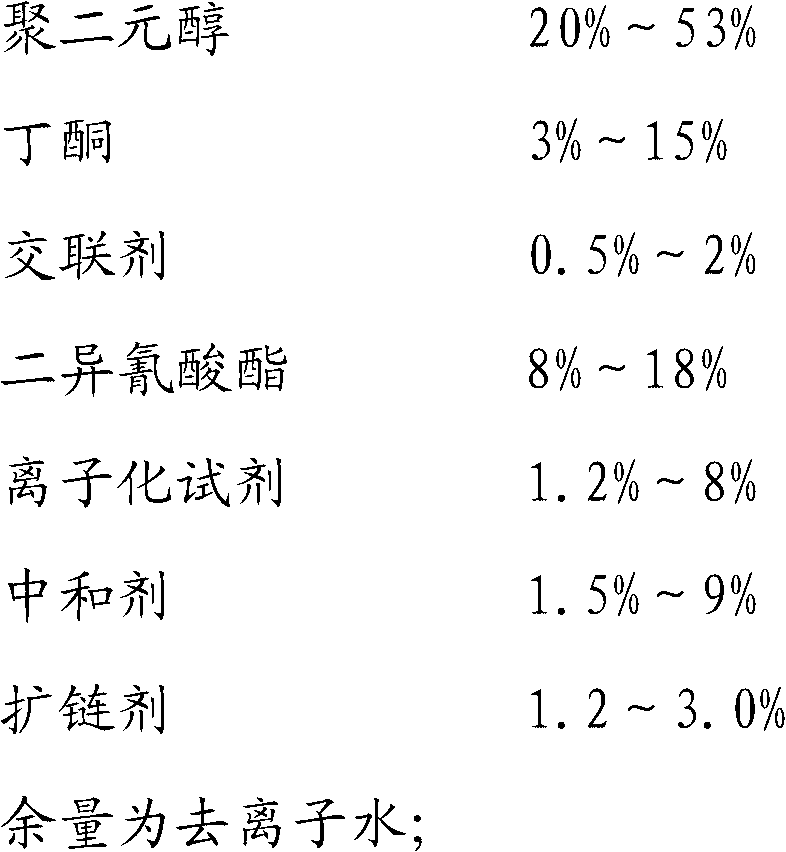

[0061] This example proposes a water-based finishing agent for PVC powder-free gloves, which can not only prevent the inner surface of PVC gloves from sticking, but also effectively prevent the generation of pinholes on the gloves, so that the PVC gloves can meet the requirement that the pinhole rate is less than 4%. , the finishing agent is specifically composed of the following components by weight percentage:

[0062] Waterborne polyacrylic resin 10%~40%

[0063] Waterborne polyurethane resin 40%~80%

[0064] Defoamer 0.1%~0.5%

[0065] Wetting and leveling agent 0.05%~3%

[0066] Anti-stick and slip agent 5%~15%

[0067] pH adjuster 0.3%~1.2%

[0068] Thickener 0.1%~2%;

[0069] During specific preparation, at a temperature of 20-40°C, fully mix the water-based polyacrylic acid resin and water-based polyurethane resin in the above formula, and add defoamer, wetting and leveling agent, anti-sticking and slipping agent, It is a pH adjuster and a thickener, and it can b...

Embodiment 2

[0094] This embodiment provides a water-based finishing agent for PVC powder-free gloves, the specific preparation method is as follows:

[0095] Get each raw material by following weight:

[0096] Water-based polyacrylic resin 30g

[0097] Water-based polyurethane resin 60g

[0098] BYK-028 (defoamer) 0.3g

[0099] CoatOSil 1211 (wetting and leveling agent) 1g

[0100] LV-461 (anti-stick and slip agent) 7.2g

[0101] 2-Amino-2-methyl-1-propanol (pH regulator) 0.5g

[0102] ASE60 (thickener) 1g;

[0103] The preparation of the finishing agent is as follows: Add 30 g of water-based polyacrylic resin and 60 g of water-based polyurethane resin into the flask at room temperature, stir at a low speed for 30 minutes, and then add 0.3 g of BYK-028 (manufacturer BYK), 1 g of CoatOSil 1211 (manufacturer Momentive) , 7.2g LV-461 (manufacturer DEUCHEM), 0.5g2-amino-2-methyl-1-propanol, 1g ASE60 (manufacturer ROHM&HAAS), after stirring evenly, the material used in the embodiment of ...

Embodiment 3

[0108] This embodiment provides a water-based finishing agent for PVC powder-free gloves, the specific preparation method is as follows:

[0109] Get each raw material component by following weight:

[0110] Water-based polyacrylic resin 15g

[0111] Water-based polyurethane resin 70g

[0112] 815N (defoamer) 0.3g

[0113] CoatOSil77 (wetting and leveling agent) 1.2g

[0114] ML-160 (anti-adhesive slip agent) 12g

[0115] 2-Amino-2-methyl-1-propanol (pH regulator) 0.5g

[0116] ASE60 (thickener) 1g

[0117] The preparation method of this finishing agent is as follows:

[0118] Add 15g of water-based polyacrylic resin and 70g of water-based polyurethane resin into the flask at room temperature, stir at a low speed for 30min, then add 0.3g 815N (manufacturer TEGO), 1.2g CoatOSil 77 (manufacturer Momentive), 12g ML-160 (manufacturer MICHELMAN), 0.5g 2-amino-2-methyl-1-propanol, 1g ASE60 (manufacturer ROHM & HAAS), stir evenly and then discharge to obtain the finishing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com