Electric can opener

A can opener and electric technology, which is applied in the direction of electric operation devices, opening closed containers, bottles/container caps, etc., can solve the problems of cutting fingers, slow speed, and laboriousness, and achieve labor intensity reduction, high speed, and easy operation. Convenient and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

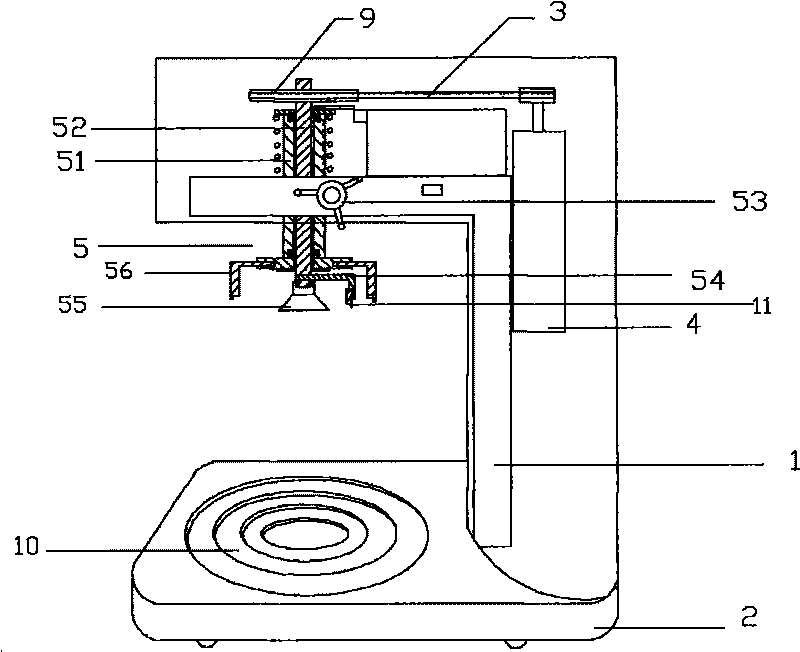

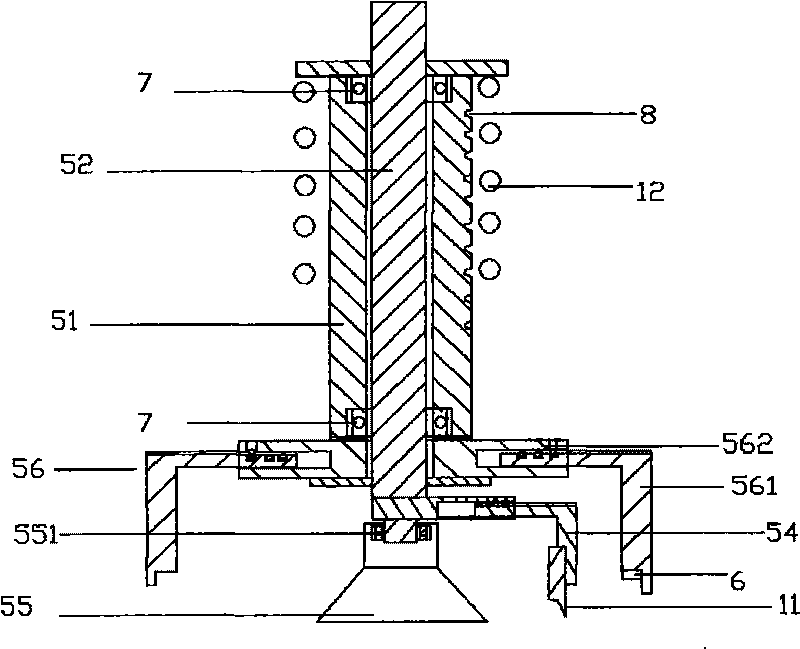

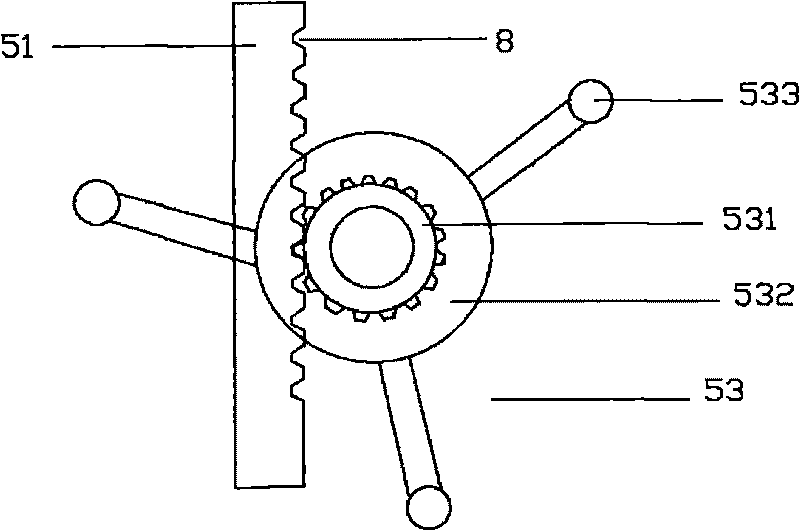

[0017] Such as figure 1 , figure 2 , image 3 As shown, it includes a main column frame (1), a base (2), a motor (4), a transmission mechanism (3), a cutting device (5), the lower end of the main column frame (1) is fixedly connected to the base (2), and the main column The side of the frame (1) is provided with a motor (4), the motor is connected to the transmission mechanism (3), the transmission mechanism is connected to the cutting device (5), the cutting device (5) is arranged on the main column horizontal frame, and the cutting device is driven by the outer shaft (51) , rotating shaft (52), manual lifting wheel (53), fixed claw (56), knife rest (54), suction cup (55), the rotating shaft (52) is located in the inner cavity of the center of the outer shaft (51), and the upper end is connected to the transmission Mechanism speed change wheel (9), the lower end is connected knife rest (54) and suction cup (55), and the knife rest arm is telescopically adjustable cutting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com