Unit type photogravure press and temperature control method

A gravure printing machine, unit type technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of high energy consumption, waste of ink, environmental pollution, etc., to achieve less evaporation, low cost, good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

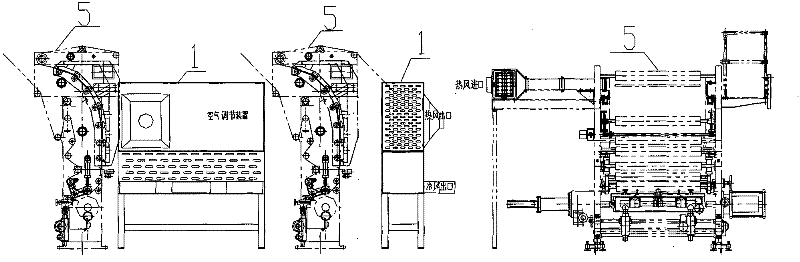

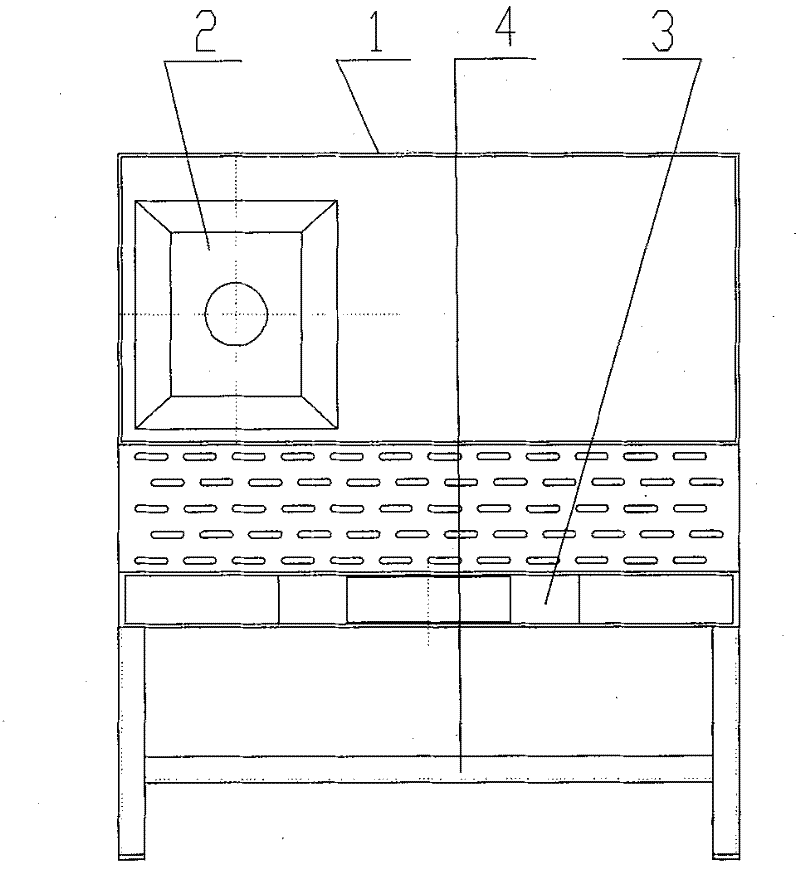

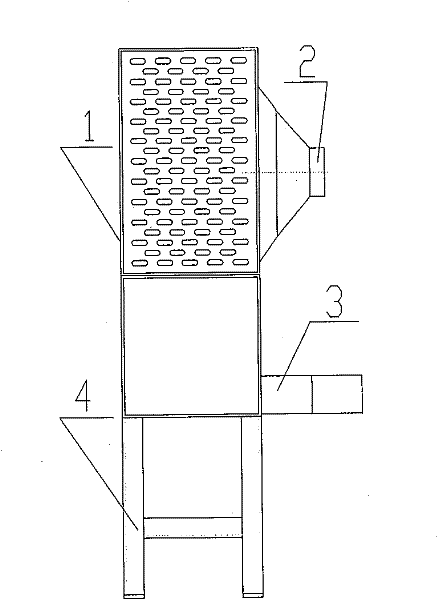

[0021] Embodiment 1: with reference to attached Figure 1~3 . A high-efficiency, energy-saving and environment-friendly unit-type gravure printing machine, which includes a unit-type gravure printing machine, an air-conditioning device 1 is installed between the unit 5 required by each channel of the unit-type gravure printing machine at a constant temperature, and the hot air outlet located on the upper part of the air-conditioning device 1 2 is connected with the inlet of the drying box in the unit-type gravure printing machine, and the lower cold air outlet 3 is located below the unit in the unit-type gravure printing machine. The upper part of the air-conditioning device 1 is a hot air outlet 2, and the lower part is a cold air outlet 3. The principle and cooling structure of the air-conditioning device 1 are prior art and will not be described here. The cold air outlet 3 is located at the middle and lower part of the air conditioning device 1 . The cold air outlet 3 is ...

Embodiment 2

[0022] Embodiment 2: On the basis of embodiment 1, the energy-saving and environment-friendly method of the high-efficiency energy-saving and environment-friendly unit-type gravure printing machine, it comprises the unit-type gravure printing machine, and the unit 5 required constant temperature of each road of the unit-type gravure printing machine is equipped with Air-conditioning device 1, the cold air generated by the cooling of air-conditioning device 1 controls the working temperature of the printing assembly of the unit-type gravure printing machine within the range of 20-25°C, so that the solvent evaporation in the ink in the printing assembly is effectively reduced Controlling and keeping the viscosity of the ink at the flow viscosity required by the design, not only the printing quality is clear, the working environment is environmentally friendly, but also the hot air generated by the cooling of the air conditioning device 1 passes through the hot air outlet 2 on its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com