Aluminum strip forming machine

A forming machine and aluminum strip technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy bending and breaking of aluminum strips, burrs on the cutting surface of the saw kerf, and non-straight finished materials, so as to reduce the cutting surface of the saw kerf Burrs, improved surface finish, good surface finish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

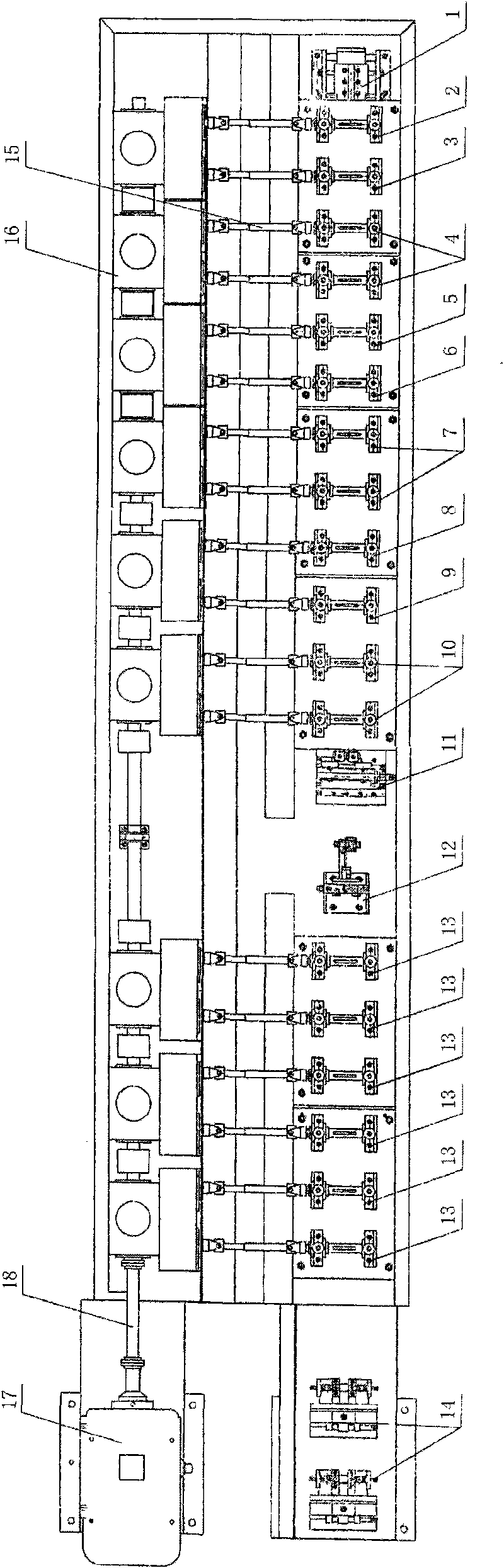

[0011] An aluminum strip forming machine, characterized in that the aluminum strip forming machine includes a feeder 1, a character mold 2, a line pressing mold 3, one or two corner pressing molds 4, a closing mold 5, an arc pressing mold 6, one or two A closing die 7, a punching die 8, a closing die 9, one or two closed dies 10, an extruder 11, a scraper 12, four shaping parts 13, one or two straighteners 14, Transmission shaft 15, gearbox 16, main shaft 18, motor 17; character mold 2, crimping mold 3, one or two angle crimping molds 4, closing mold 5, arc pressing mold 6, one or two reclosing molds 7, Punching mold 8, rear closing mold 9, one or two closed molds 10, four plastic parts 13 are respectively connected with a transmission shaft 15, each transmission shaft 15 is respectively connected with a gearbox 16, each gearbox 16 is connected to a main shaft 18, and one end of the main shaft 18 is connected to the motor 17; multiple gearboxes 16, the main shaft 18 and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com