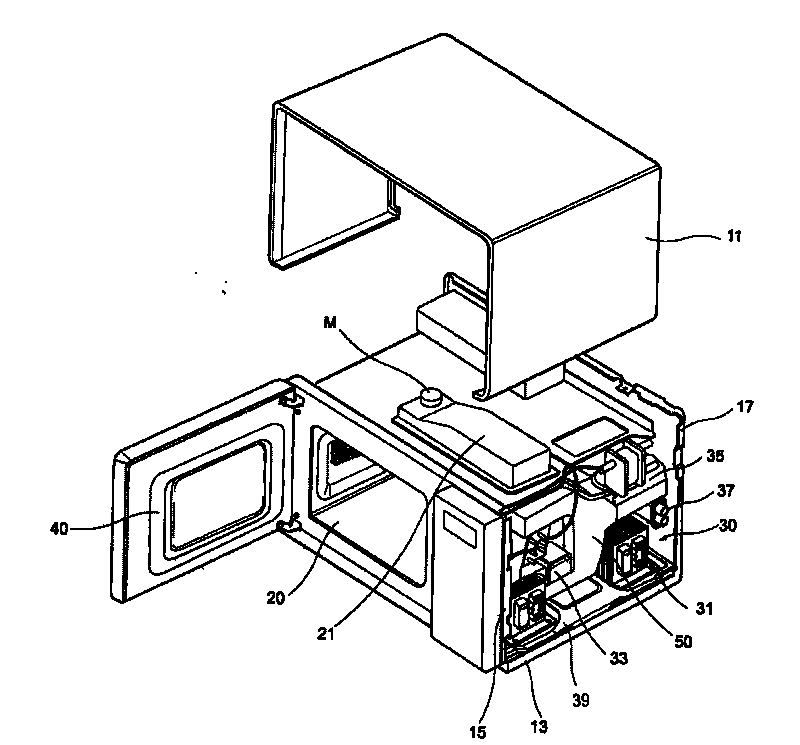

Transformer structure of microwave oven

A technology for transformers and microwave ovens, applied in the field of microwave ovens, can solve the problems of transformers with small ventilation and heat dissipation area, affect the heat dissipation efficiency of transformers, and the heat cannot be dissipated in time, and achieve the effects of facilitating ventilation and heat dissipation, reducing temperature, and reducing overall structural noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

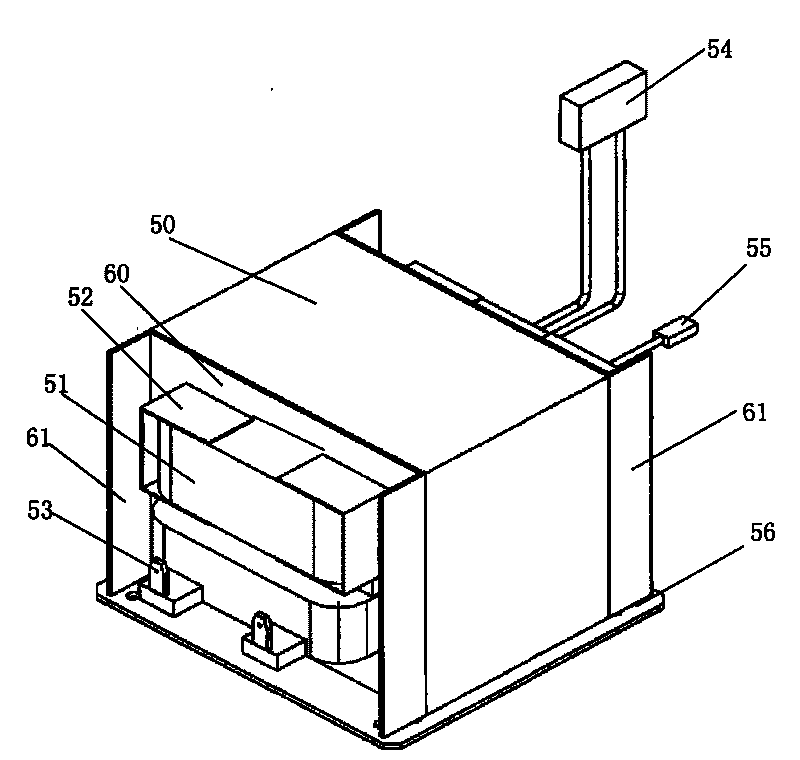

[0022] The present invention will be described in detail below with reference to the drawings and embodiments:

[0023] image 3 It is a schematic diagram of the transformer structure of the microwave oven of the present invention.

[0024] Such as image 3 As shown, the transformer structure of the microwave oven of the present invention includes: an iron core 50 formed by closely arranging a plurality of silicon steel sheets 60, so that a magnetic shunt with a high reluctance gap is formed in the transformer. A certain amount of leakage flux will be generated in the circuit, which controls the output current of the transformer to keep the working current of the magnetron relatively stable; the coil 51 wound on the iron core to generate a predetermined voltage passes through the primary coil and the secondary coil The interaction converts 220V mains power into a filament voltage of 3.3V or a working voltage of about 2100V; separates different groups of coils or separates the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com