IC test device

A test device and test probe technology, applied in the direction of measurement device, electronic circuit test, measurement of electricity, etc., can solve problems such as poor test yield and failure of test probes to achieve good contact, and achieve the effect of avoiding test failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Since the present invention provides an IC testing device, the principle of testing integrated circuit components used therein has been understood by those skilled in the art, so it will not be fully described in the following description. At the same time, the drawings compared below are schematic representations related to the features of the present invention, and are not and need not be completely drawn according to the actual situation and described in advance.

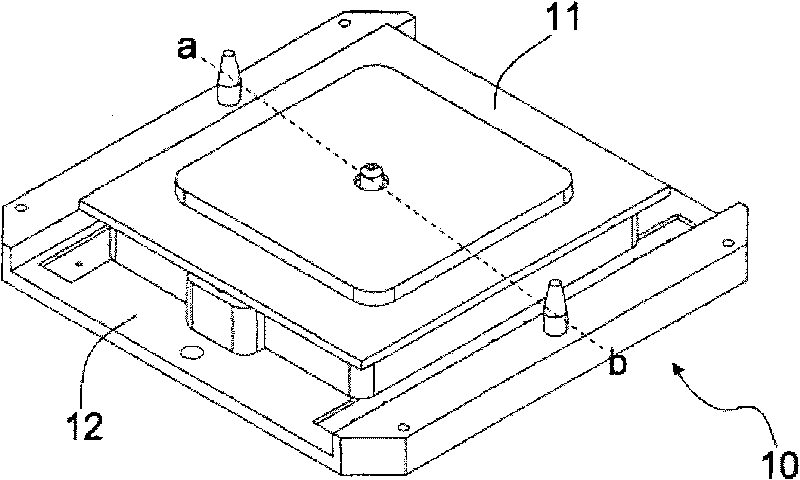

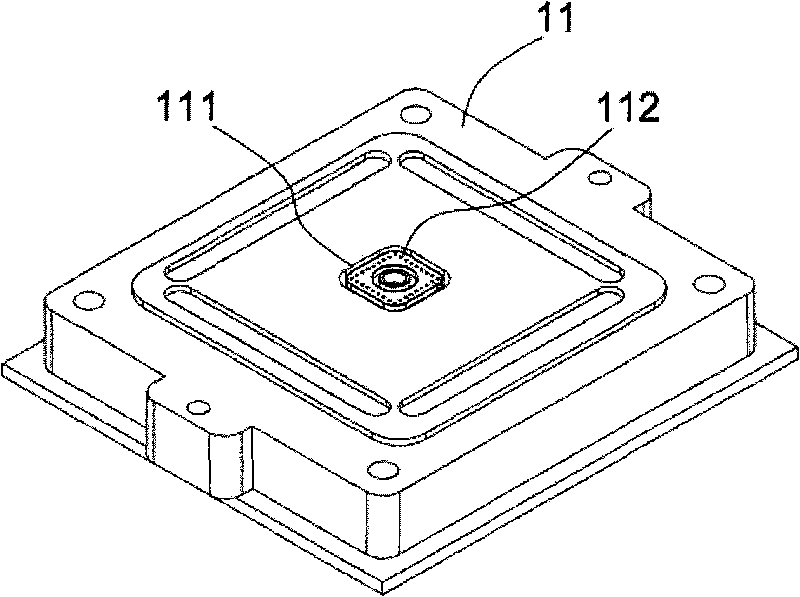

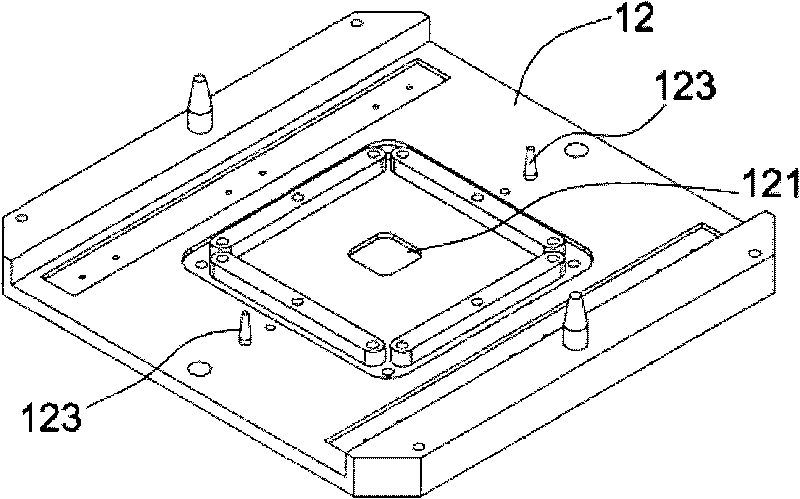

[0031] Please refer to figure 1 , is a schematic diagram of the IC testing device 10 of the first preferred embodiment provided by the present invention. The IC testing device 10 for testing after IC packaging mainly includes a top cover 11 (contact blade) and a base 12 (socket) assembled with each other. In a preferred implementation state, the IC testing device 10 is used for packaging and testing (CLCC, Ceramic Leaded Chip Package) of ceramic leaded chip carriers in image sensors.

[0032] Please cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com