Wind driven generator coupler test-bed and test method

A coupling test bench and wind power generator technology, applied in the field of test benches, can solve the problems of unknown test methods and device structures, no test devices, etc., to achieve true and reliable test data, easy operation, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

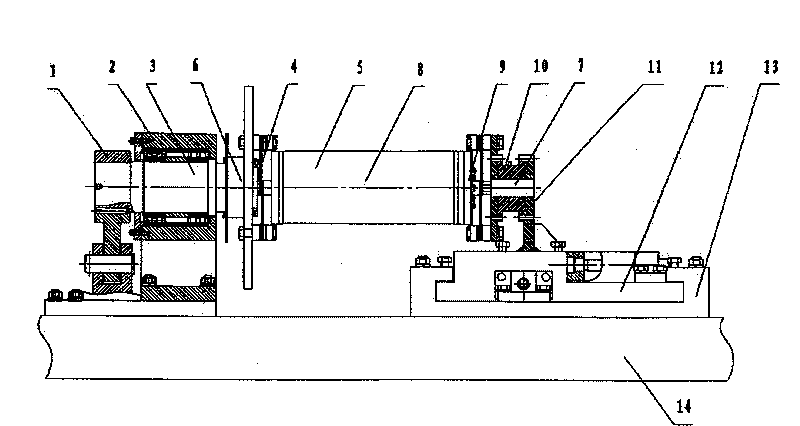

example 1

[0045] Example 1: Slip torque test

[0046] The specific steps of slip torque calibration are:

[0047] 1. Preparation steps:

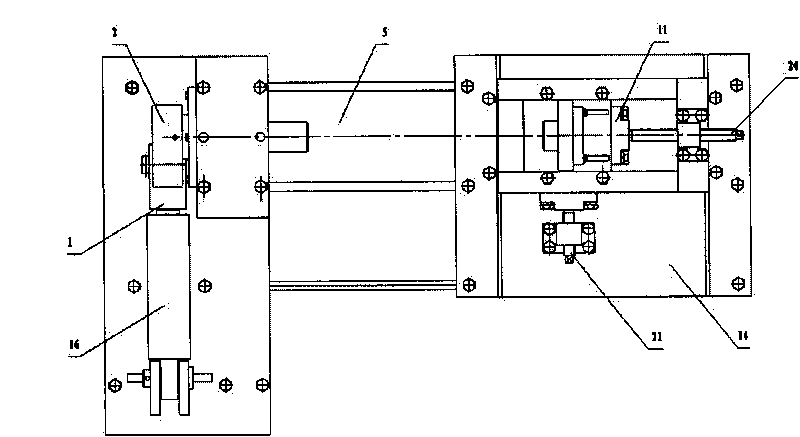

[0048] -Put a pad 13 of the same height under the right support 11, and adjust the axial adjustment screw 20 and the radial adjustment screw 2, so that the left support 2 and the right support 11 are concentric;

[0049] - Install the coupling 5 on the left support 2 and the right support 11 of the test bench. When installing, remove the spring diaphragm 4 at one end of the torque limiter 8 of the coupling 5 so that the output joint of the coupling 5 7 is rigidly connected with the torque limiter 8.

[0050] 2. Test steps:

[0051] A. Set the tightening torque of the torque wrench to 140Nm, tighten the fastening screws 9 on the torque limiter 8, so that the pressing force of each fastening screw 9 is consistent;

[0052] B. Draw an axial scale line on the peripheral surface of the joint of the taper sleeve and the friction flange of the torque lim...

example 2

[0065] Example 2: Maximum load test

[0066] The specific steps of the maximum load test are:

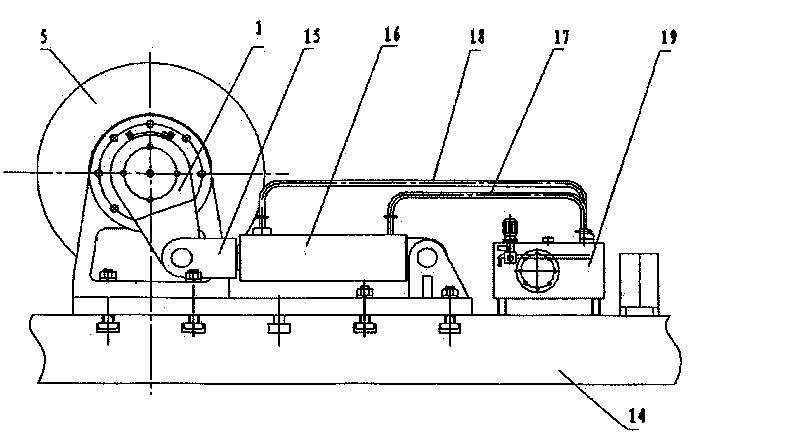

[0067] A. Install the coupling 5 as a whole on the test bench, place a 0.2° wedge-shaped pad 13 between the T-shaped floor-standing table 14 and the supporting plate 12, and make the right support 11 axially tilt; then adjust the diameter Adjust the bolt to make the right support 11 move 12mm in the radial direction of the coupling 5; adjust the axial adjustment bolt to move the right support 11 4mm in the axial direction of the coupling 5, and then lock the right support 11 at T 14 on the floor-standing workbench;

[0068] B. Increase the tightening torque of the wrench by 20Nm on the basis of the slipping torque, and tighten the fastening screw 9 on the torque limiter 8;

[0069] C. Jog the start button of the hydraulic cylinder 16, and when the output data of the torque sensor 10 reaches the required maximum load, lock the overflow valve 24 of the hydraulic system, keep the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com