Method for measuring nozzle flow characteristic of inert gas fire-extinguishing system

A technology of fire extinguishing system and flow characteristics, which is applied in the field of measuring the flow characteristics of nozzles of inert gas fire extinguishing systems, can solve the problems of complex measuring devices and measuring procedures, influence on the accuracy of measuring results, data asynchrony, etc., so as to improve the measuring work efficiency, The effect of simplifying the measuring device and measuring procedure and improving the measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described further below: a kind of measuring method of nozzle flow characteristic of inert gas fire extinguishing system comprises the steps:

[0017] (1) Install the static pressure, dynamic pressure or total pressure sensor and temperature sensor on the same section of the upstream pipeline of the nozzle, and measure the static pressure, dynamic pressure or total pressure and temperature at the position of the section;

[0018] (2) Measure and calculate the cross-sectional area of the pipeline at the pressure measuring point and the area of the nozzle outlet;

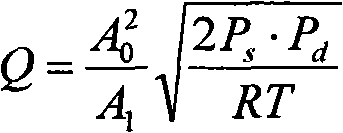

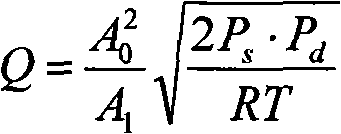

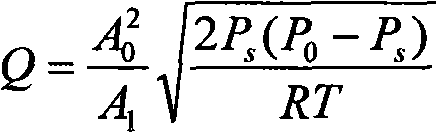

[0019] (3) Substitute the measured static pressure value, dynamic pressure or total pressure value, temperature value, pipe cross-sectional area value at the pressure measurement point and nozzle outlet area value into the flow calculation formula of the nozzle ejected gas:

[0020] Q = A 0 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com