Method for determining thickness of single-event sensitive volume of device

A volume-sensitive, single-particle technology that can be used in instruments, optical devices, measuring devices, etc., to solve problems such as errors between estimated results and actual accurate results

Active Publication Date: 2010-06-09

NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem that there is a large error between the estimated result and the actual accurate result due to the lack of accurate data on the thickness of the sensitive volume of the device in the prior art, and proposes a method for determining the single event sensitive volume of the device thickness method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0030] (1) Based on the laser simulation system in the laboratory, the single-event flip test of two IDT 71256SRAMs and two IDT6116SRAMs has been completed. In the experiment, two kinds of lasers with λ1 of 1064nm and λ2 of 1079nm were used to irradiate the same position of the test sample to obtain the energy threshold of the single event effect of the sample, as shown in Table 1 and Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for determining the thickness of single-event sensitive volume of a device, which belongs to the fields of space radiation effects and reinforcement technology. The method comprises the steps of calculating deposited energy of laser in the sensitive volume, and generating single event effects when deposited charges of the laser in a sensitive volume unit of the device achieve or exceed the critical charges of the device, wherein the critical charges of the single-event effects under different pulsed laser wavelengths are the same; and the laser of a laser simulation system is used for inducing, obtaining energy threshold data of the single-event effects and further obtaining the thickness of the sensitive volume (Sv) of the single-event effects. The method has no radiation injury to the device and laboratory staff, very simple operation, low cost and capability of precisely measuring the thickness of the sensitive volume of the device.

Description

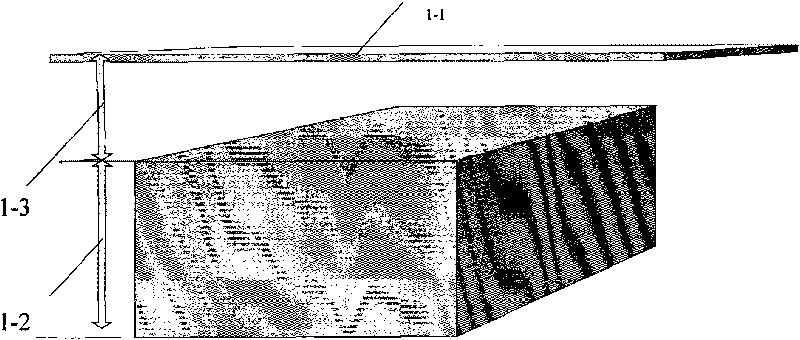

technical field [0001] The invention relates to a method for determining the thickness of a single particle sensitive volume of a device, and belongs to the technical field of space radiation effect and reinforcement. Background technique [0002] The thickness of the sensitive volume (Sv) is a key parameter in estimating the single event effect (SEE) of space and aerospace microelectronic devices. This is because the concept of Sv is used in most models for estimating the probability of SEE. It is based on the RPP model, assuming that the sensitive volume of the device is a cuboid. The thickness of Sv is related to the device type, device process, etc., and varies greatly among different devices. Due to the lack of accurate data on the thickness of the device Sv in China, the thickness of 2 μm is usually used instead in the probability estimation of the device space single event event (SEP), which causes a large error between the estimated result and the actual accurate re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01B11/06

Inventor 薛玉雄田恺马亚莉杨生胜曹洲

Owner NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com