Efficient brightening backlight module

A backlight module and high-efficiency technology, which is applied in the field of backlight modules, can solve the problems of poor light directivity and difficulty in improving the brightness of backlight modules, and achieve the effects of improving utilization, brightness and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

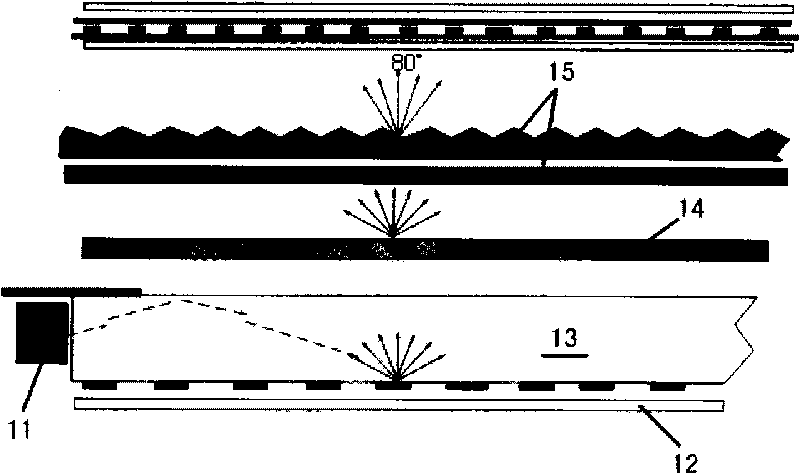

[0027] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

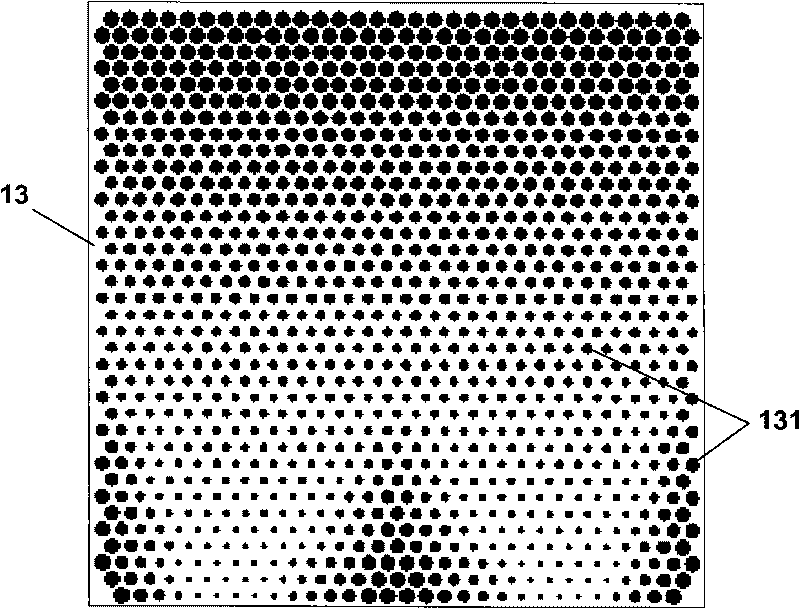

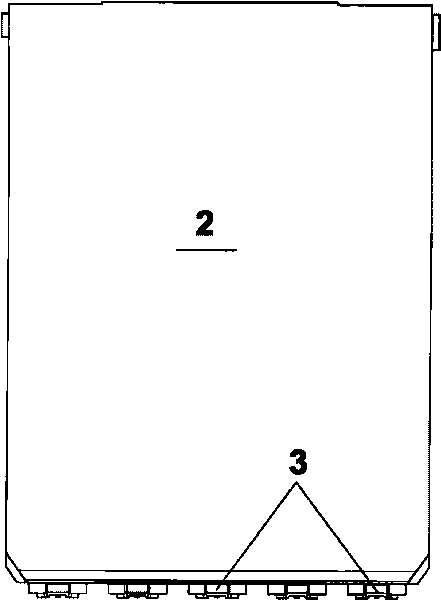

[0028] Such as image 3 As shown, the backlight module of the present invention includes a light guide plate 2 and a light source 3 disposed on one side of the light guide plate 2 . Such as Figure 4 , the six surfaces of the light guide plate 2 are respectively: the vertical side near the light source 3 at the front is the light incident surface 21, the top surface is the light exit surface 22, the bottom surface 23 is close to the reflective film, and the vertical sides of the left and right sides are side surfaces 24 and 25 , and a rear surface 26 opposite to the light-incident surface 21 . The present invention mainly aims to improve the light-incident surface 21 , the light-exit surface 22 , and the bottom surface 23 .

[0029] For convenience of description, such as Figure 4 As shown, we define: take the length direction of the light-inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com