Material limiting device of round pipe rack type conveyor

A round pipe belt type and conveyor technology, which is applied in the direction of conveyor, transportation and packaging, etc., which can solve the problems of high cost, large particle size materials entering the pipe, damage to the conveyor belt and idler group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

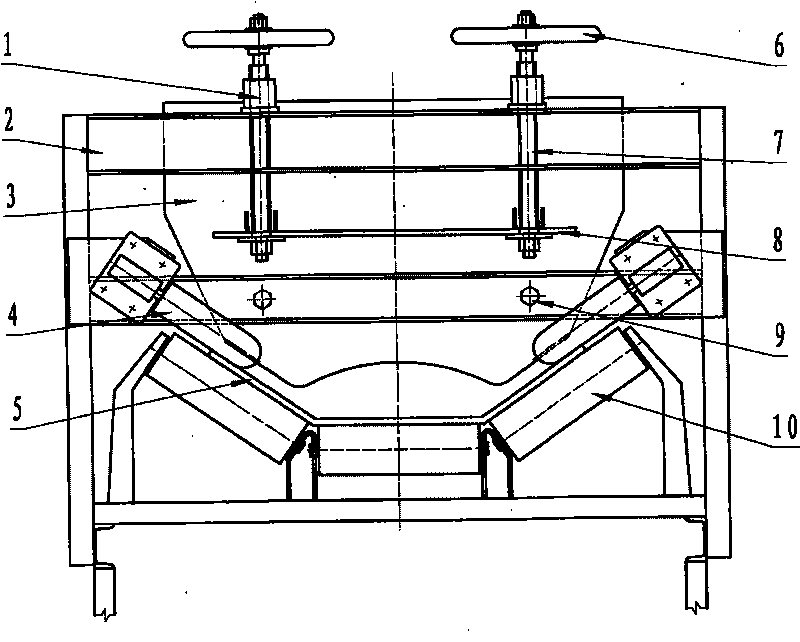

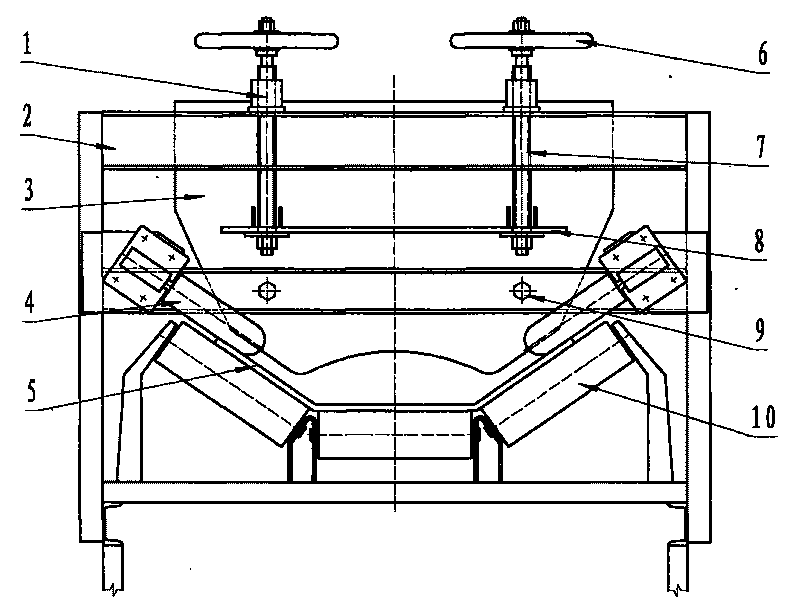

[0005] In order to solve the problem that the amount of material entering the conveyor belt is too large or the particle size is too large, a baffle 3 can be installed on the upper part of the trough-shaped conveyor belt at the tail of the conveyor belt. The bottoms are opposite to form a material chamber. The height of the material chamber is determined according to the size limit of the particle size of the material and the filling amount of the material. The two sides of the lower end of the baffle are a slope that matches the slope of the trough-shaped conveyor belt. Two vertical holes are arranged on the horizontal plate vertically connected with the door frame provided on the top, and two nuts are fixed on this horizontal plate so that the threaded holes are opposite to the vertical holes of the horizontal plate. The threads are matched, and the cylinder at the bottom is transferred to the hole of the horizontal plate 8 vertically connected with the baffle plate. The exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com