Vibration reduction block and front suspended crossbeam provided with same

A vibration-damping block and front suspension technology, applied in the directions of transportation and packaging, substructure, vehicle components, etc., can solve the problems of reducing the area and reducing the overall modal of the front suspension beam, so as to reduce vibration and improve NVH. Performance, Natural Frequency and Resonant Amplitude Convenient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

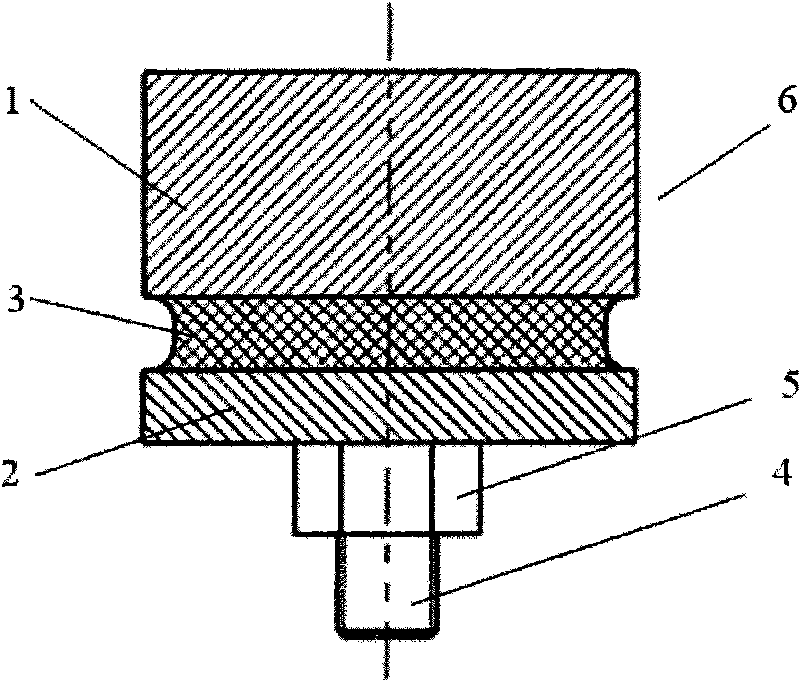

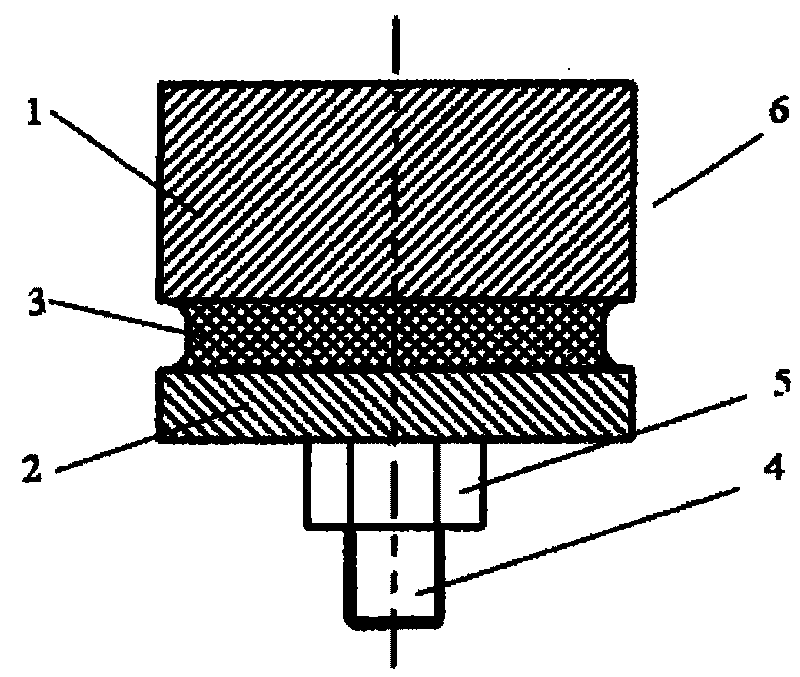

[0019] Such as figure 1 As shown, the damping block 6 of this embodiment includes a counterweight 1, a mounting base 2 and a damping block 3 made of rubber, and the damping block 3 is bonded between the counterweight 1 and the mounting base 2 by vulcanization , the bottom of the installation base 2 is provided with installation bolts 4 and lock nuts 5 .

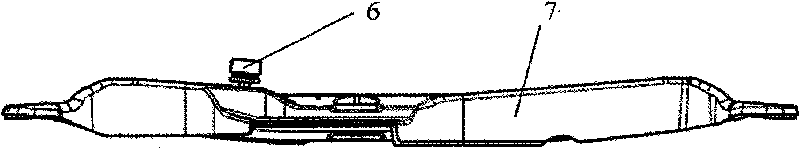

[0020] Such as figure 2 As shown, due to the limitation of the installation space, the above-mentioned damping block 6 is assembled in the middle left position of the front suspension beam 7, which is as close as possible to the position where the vibration displacement of the front suspension beam 7 is the largest. The natural frequency of the vibration damping block 6 Consistent with the resonance frequency of the front suspension beam 7, it can significantly reduce vibration and improve the NVH performance of the car.

[0021] The mass of the counterweight 1 is about 400 grams, which is equivalent to about 1 / 8 of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com