Flow passage of helical-tooth drip irrigation emitter

A technology of emitters and flow channels, which is applied in the field of helical drip irrigation emitter flow channels, can solve problems such as manufacturing complexity, and achieve the effects of improving hydraulic performance, reducing stagnant areas, and enhancing anti-clogging capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

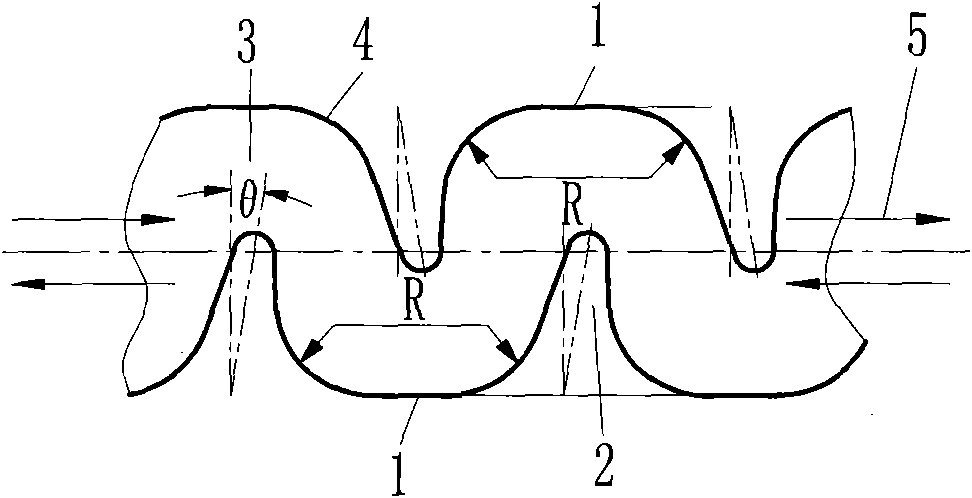

[0031] like figure 1 , figure 2 As shown, the trough-shaped flow channel formed by the boundary 1 and the flow channel depth 6 has protruding flow channel teeth 2 in the trough-shaped flow channel, and the dedendum of the flow channel teeth 2 forms an arc with the upper or lower boundary 1 Chamfer 4, a flow channel unit is composed of boundary 1, arc chamfer 4, runner teeth 2 and arc chamfer 4, the runner teeth 2 in the upper and lower runner units are arranged in a staggered manner, and several identical runner units are sequentially connected end to end to form an integral flow channel; the tooth tops of the flow channel teeth 2 are arc-shaped, and the tooth top arcs of the upper and lower flow channel teeth 2 extend into the other side of the center line of the flow channel; the flow channel The centerline of the road tooth 2 is inclined 15° to the right in the direction perpendicular to the centerline of the runner (of course, 0-45° to the left or right is valid), formin...

Embodiment 2

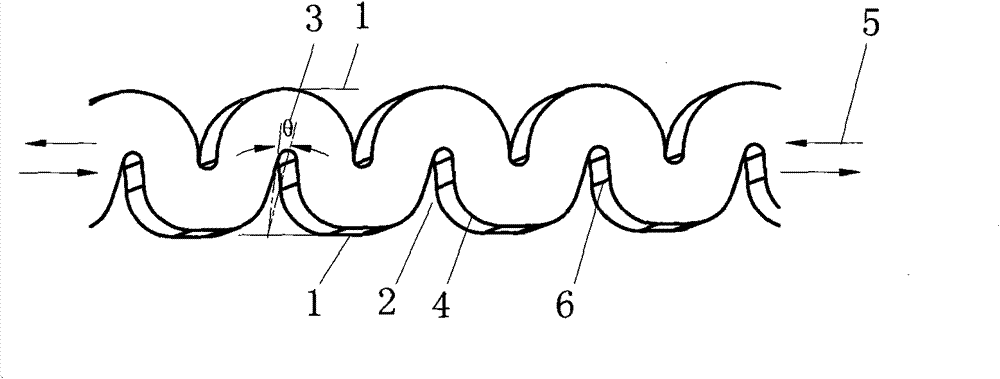

[0034] like image 3 , Figure 4 As shown, the basic structure is the same as that of Embodiment 1, and the difference from Embodiment 1 is that the upper boundary of the flow channel is in the shape of a semicircle. This change of the boundary can further improve the anti-clogging performance of the emitter. The x value of the channel structure of this embodiment is between 0.4792-0.4944.

Embodiment 3

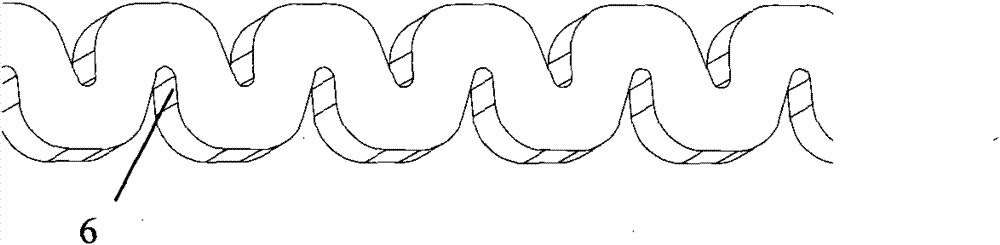

[0036] like Figure 5 , Image 6 As shown, the basic structure is the same as that of Example 1, and the difference from Example 1 is that the upper and lower boundaries of the flow channel are both semi-circular arc-shaped. The change of this boundary can further improve the anti-clogging performance of the emitter, but the hydraulic performance will be affected, the x-values drop somewhat, but not significantly. The x value of the channel structure of this embodiment is between 0.5129 and 0.5137.

[0037] In actual production, the above several embodiments can be selected and used according to local crop varieties and economic conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com