Centralized dust collecting system

A vacuum system and centralized technology, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of high environmental cost, low economic benefit, and severe noise, and achieve low cost, improved cleaning effect, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

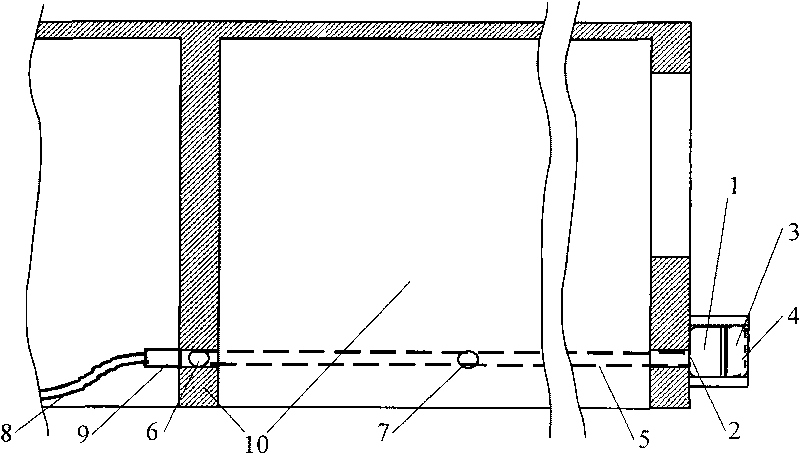

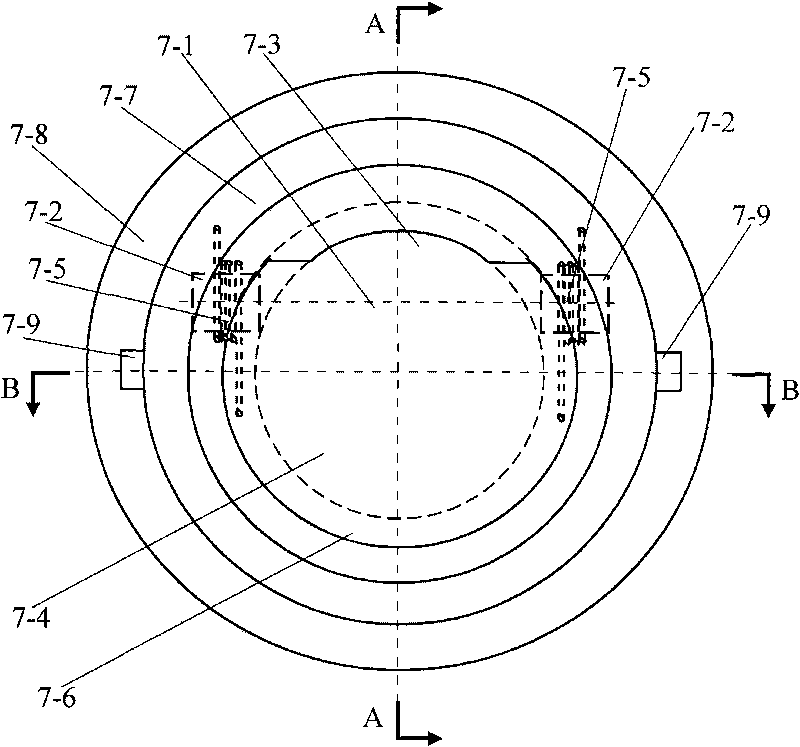

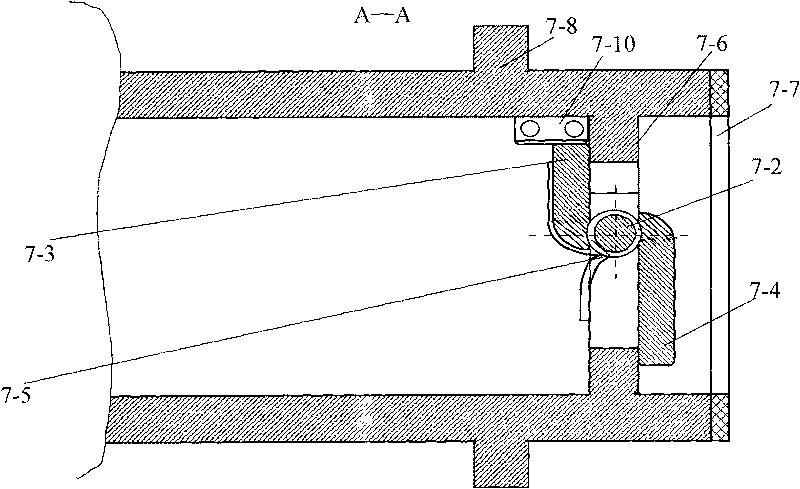

[0017] In the embodiment shown in the drawings, the existing vacuum cleaner main unit (1) is fixedly installed on the outer wall of the room or in a convenient operating position in the open exhaust duct, and the exhaust end is outward; the main dust suction pipe (5) It is fixedly connected with the dust suction port (2) of the main engine, and laid in the wall (10) where it is located. The main dust suction pipe (5) is connected with the dust suction pipes of each room, and the dust suction pipes (6) of the rooms are laid indoors In each partition wall (10), the compartment dust suction pipe (6) has a socket (7) for inserting the terminal dust suction pipe (8) in each compartment; type structure, the valve (7-1) is installed on the air seal limit ring (7-6) through the shaft (7-2), and the shaft (7-2) divides the valve (7-1) into an inner flap ( 7-3) and outward flap (7-4), the springs (7-5) set at the two ends of the shaft (7-2) are used to keep the valve (71) closed reliabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com