Liquid electrolyte battery with electrolyte mixing by convection current

A liquid electrolyte and electrolyte technology, which can be used in large-sized batteries/batteries, small-sized batteries/batteries, transfer electrolyte devices, etc., which can solve the problems that batteries cannot reach full power and reduce battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

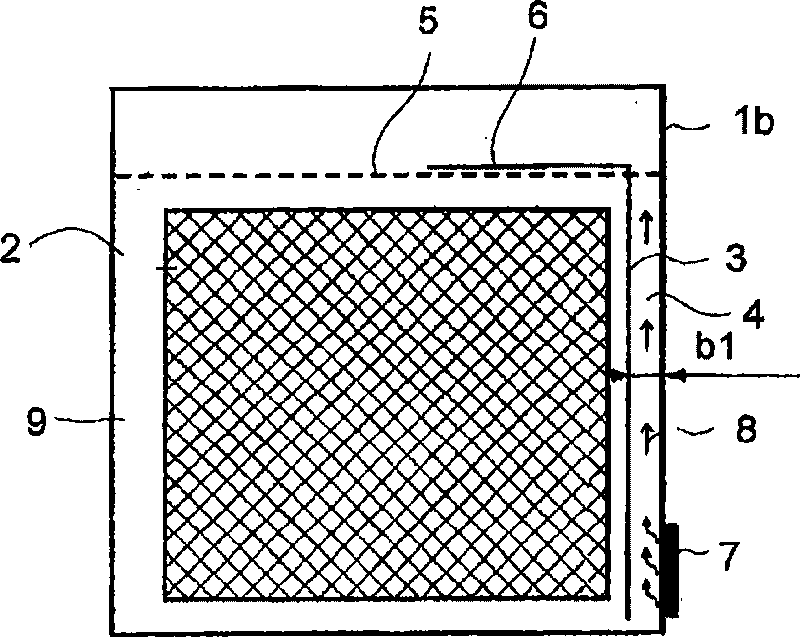

[0028] Figure 5 A battery box with 6 cells is shown. However, all of the following descriptions refer only to a single cell, which is in the Figure 1a with 1b in accordance with Figure 5 The sectional view of the 1c direction is shown. Because the cell is also an independent battery, only the battery is discussed below, because the present invention can be used not only for a single cell, but also for a combination of multiple cells.

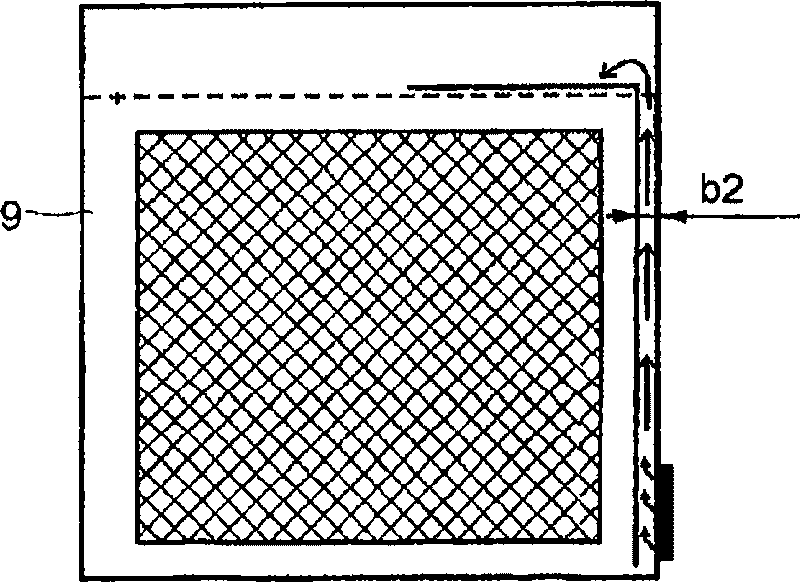

[0029] according to Figure 1a A flow channel plate 3 is arranged between the vertical housing wall 1 b and the side edges of the electrode plates 2 , so that a flow channel 4 is formed between the flow channel plate 3 and the housing wall 1 b. The upper edge of the flow channel plate 3 is located in the region of the electrolyte level 5 and is connected to a drain plate 6 which extends parallel to the upper edge of the electrode plate 2 towards the center of the housing. In the region of the lower end section of the flow channel 4 , a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com