Drive pulleys

A technology for driving pulleys and motors, used in belts/chains/gears, transmissions, electric components, etc., and can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

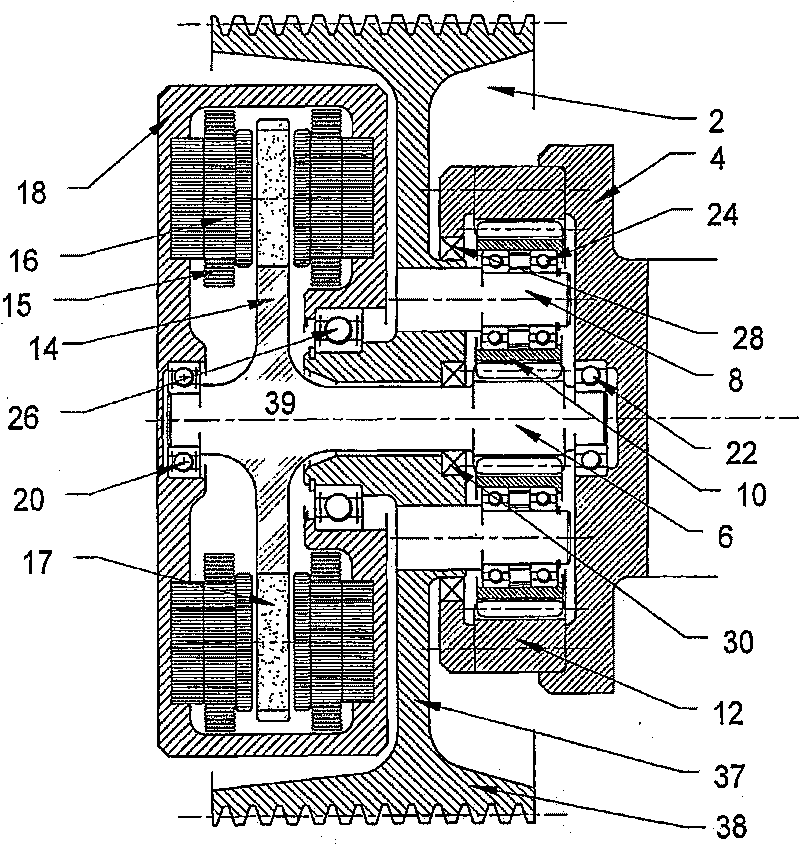

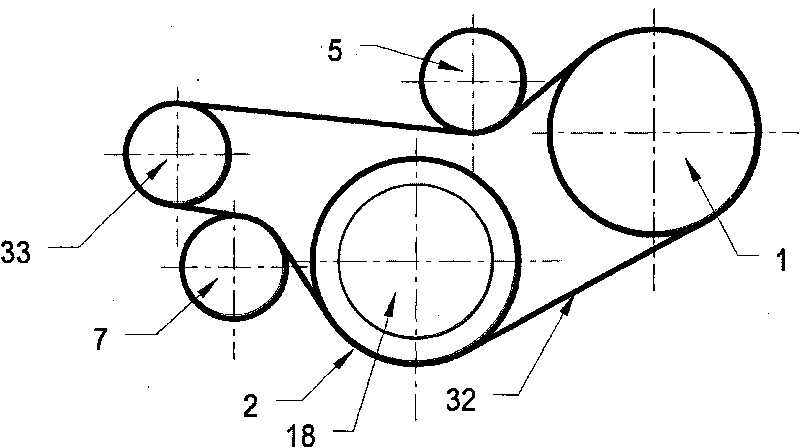

[0025] See first figure 1 , image 3 with Image 6 , The pulley shown is shown connected to one end of the crankshaft 4 of the transversely mounted engine 80 of the front-engine car. The crankshaft 4 is connected to the input end of a transmission system including a planetary gear set, and the output end of the transmission system is connected to the pulley member 2 including radial spokes 37 connected to the free edge portion of the pulley member 2 The free edge portion is a hollow cylindrical member 38, the outer circumferential surface of the cylindrical member 38 is provided with a plurality of V-shaped grooves, and constitutes the driving belt engaging surface of the multi-groove V-belt wheel.

[0026] The planetary gear set includes a sun gear 6 which constitutes an extension of a rotatable central shaft 39. The sun gear meshes with two or more planetary gears 10, which are mounted on respective planetary shafts 8 through corresponding bearings 24 inserted so as to be able...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com