Speaker vibration film made of non-wood fibers and manufacture process thereof

A wood fiber and manufacturing process technology, applied in the field of loudspeaker diaphragms, can solve the problems of declining economic benefits, small differences in physical properties, single features, etc., and achieve the effects of good economic benefits, cost control, and good cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

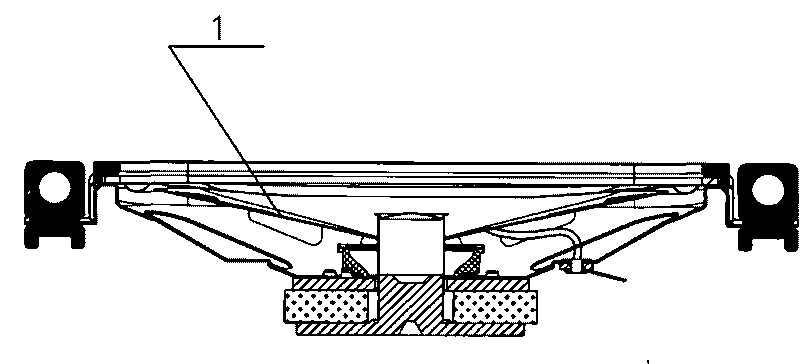

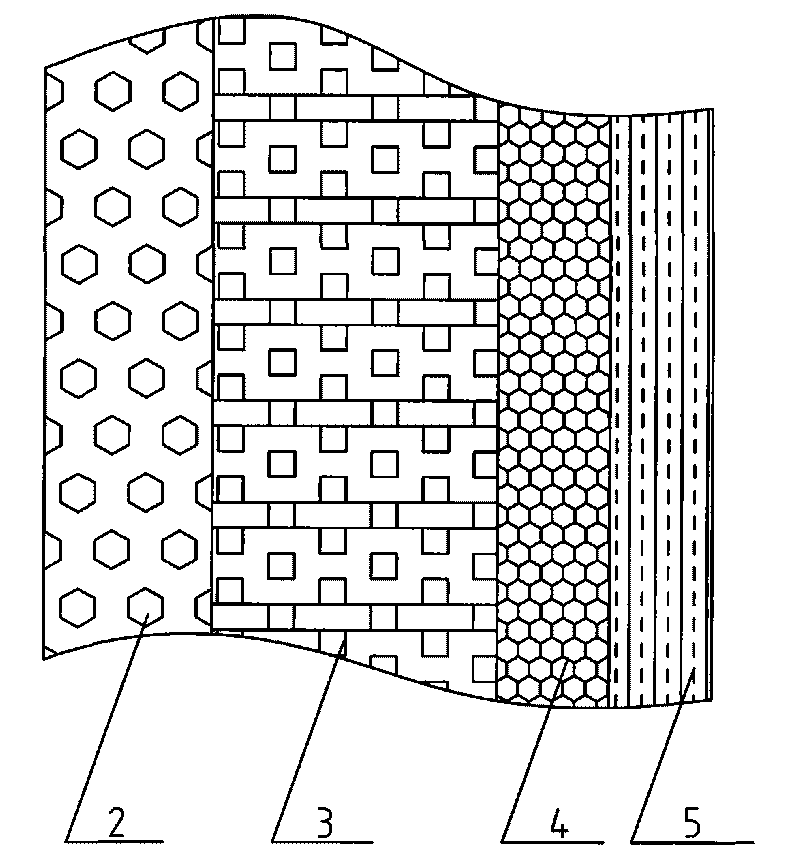

[0055] The loudspeaker diaphragm 1 raw material of the present embodiment is made up of Spanish grass fiber, cotton fiber, Manila hemp fiber, as follows:

[0056]

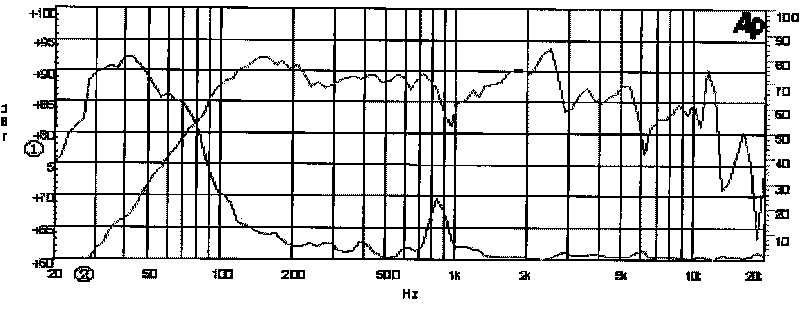

[0057] image 3 Horn curve diagram for loudspeaker diaphragm 1 manufactured for conventional wood fiber. Line ① is the frequency response curve of the speaker, and Line ② is the distortion curve of the speaker.

[0058] Figure 4 It is the speaker curve diagram of the speaker diaphragm 1 of the present embodiment. Line ① is the frequency response curve of the speaker, and Line ② is the distortion curve of the speaker.

[0059] Will Figure 4 and image 3 For comparison: in the low frequency band, before 1KHz, image 3 and Figure 4 The speaker curve is similar, at high frequency, after 1KHz, Figure 4 Curve ratio image 3 The overall sound pressure level is high. Distortion curve comparison: Figure 4 The distortion peaks at only about 6%, while the image 3 The highest distortion reaches 25%. There...

Embodiment 2

[0061] The loudspeaker diaphragm 1 raw material of the present embodiment is made up of Spanish grass fiber, cotton fiber, Manila hemp fiber, as follows:

[0062]

[0063] Figure 5 It is the speaker curve diagram of the speaker diaphragm 1 of the present embodiment. Line ① is the frequency response curve of the speaker, and Line ② is the distortion curve of the speaker. Will Figure 5 and image 3 In comparison, it can also be seen that the loudspeaker diaphragm 1 of this embodiment has a horn performance that can reach or even surpass that of a speaker diaphragm 1 made of conventional wood fiber.

Embodiment 3

[0065] The loudspeaker diaphragm 1 raw material of the present embodiment is made up of Spanish grass fiber, cotton fiber, Manila hemp fiber, as follows:

[0066]

[0067] Figure 6 It is the speaker curve diagram of the speaker diaphragm 1 of the present embodiment. Line ① is the frequency response curve of the speaker, and Line ② is the distortion curve of the speaker. Will Figure 6 and image 3 In comparison, it can also be seen that the loudspeaker diaphragm 1 of this embodiment has a horn performance that can reach or even surpass that of a speaker diaphragm 1 made of conventional wood fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com