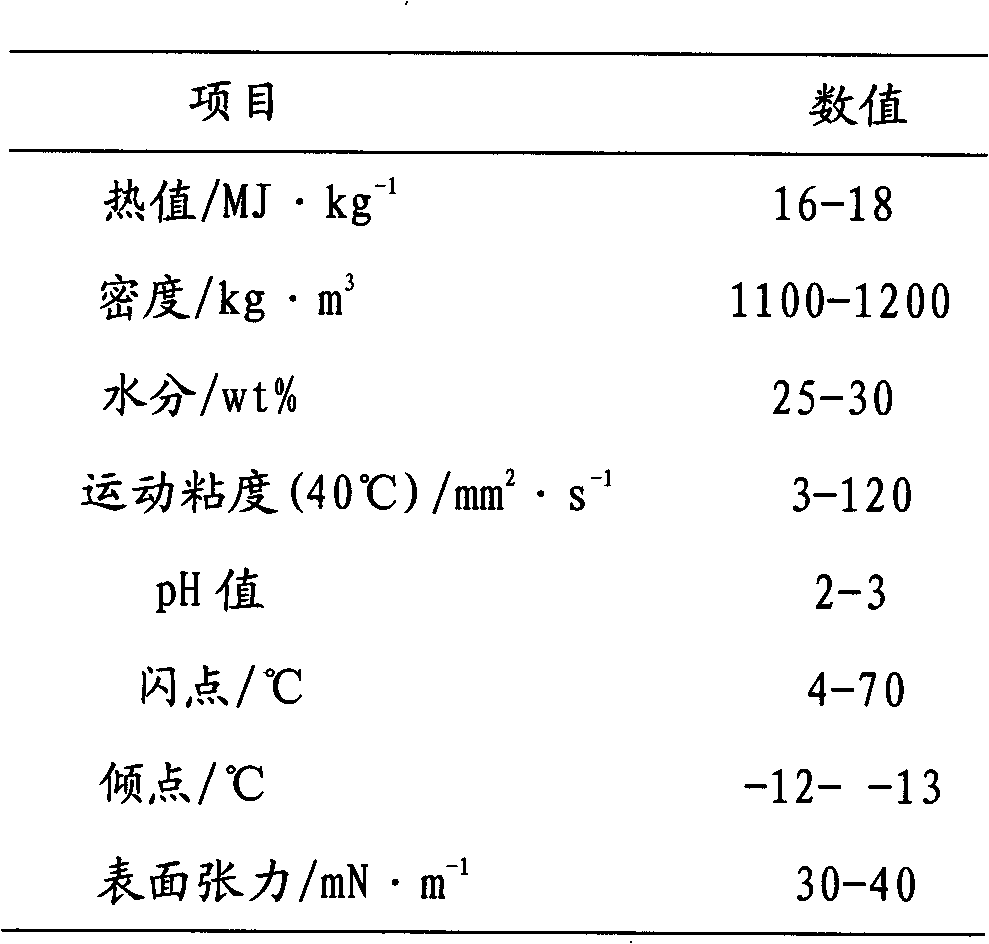

Method for improving oxidation stability of biomass crude oil

A biomass crude oil, oxidation stability technology, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc. Add simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a beaker, stir and dissolve the thioether compound in ethanol at 20°C to form a solution containing 30% by weight of the thioether compound, then add the solution to the biomass crude oil, and stir at 20°C for 10min , and finally pre-filtered. Put the filtered 350ml sample into an oxidation tube, feed oxygen at a rate of 50ml / min, oxidize at 40°C for 4h, then cool the oxidized sample to room temperature, and filter to obtain filterable insolubles. Use absolute ethanol to wash the adhesive insoluble matter from the wall of the oxidation tube and the oxygen pipe, and evaporate the absolute ethanol to obtain the adhesive insoluble matter. The sum of the amount of filterable insoluble matter and the amount of adhesive insoluble matter is the amount of total insoluble matter, expressed in mg / 100ml.

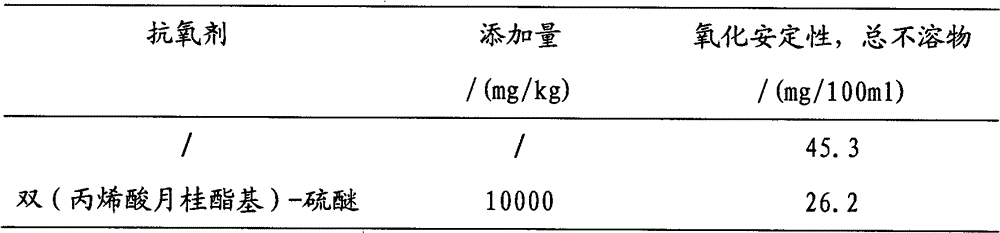

[0026] The antioxidant effect of antioxidant in the present embodiment sees the following table:

[0027]

Embodiment 2

[0029] In a beaker, dissolve the thioether compound in the biomass crude oil while stirring at 20° C. to form a masterbatch of 50% by weight of the thioether compound, and then add the masterbatch to the biomass crude oil, Stir at 25°C for 20 min, and finally pre-filter. Put the filtered 350ml sample into an oxidation tube, feed oxygen at a rate of 50ml / min, and oxidize at 95°C for 4 hours, then cool the oxidized sample to room temperature, and filter to obtain filterable insolubles. Use absolute ethanol to wash the adhesive insoluble matter from the wall of the oxidation tube and the oxygen pipe, and evaporate the absolute ethanol to obtain the adhesive insoluble matter. The sum of the amount of filterable insoluble matter and the amount of adhesive insoluble matter is the amount of total insoluble matter, expressed in mg / 100ml.

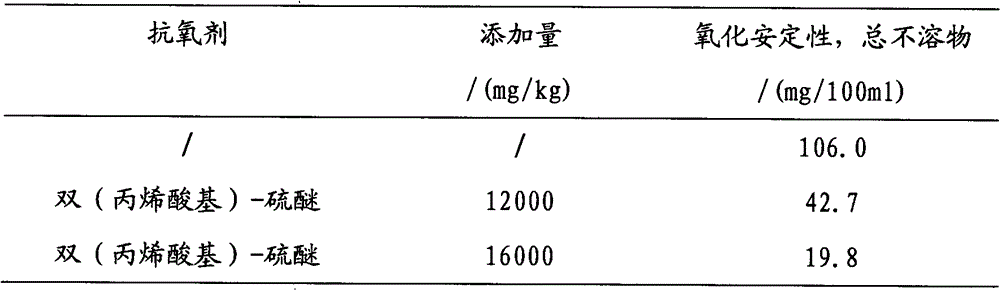

[0030] The antioxidant effect of antioxidant in the present embodiment sees the following table:

[0031]

Embodiment 3

[0033] In a beaker, dissolve the thioether compound in the biomass crude oil while stirring at 20° C. to form a masterbatch of 40% by weight of the thioether compound, and then add the masterbatch to the biomass crude oil, Stir at 25°C for 15 min, and finally pre-filter. Put the filtered 350ml sample into an oxidation tube, feed oxygen at a rate of 50ml / min, and oxidize at 95°C for 4 hours, then cool the oxidized sample to room temperature, and filter to obtain filterable insolubles. Use absolute ethanol to wash the adhesive insoluble matter from the wall of the oxidation tube and the oxygen pipe, and evaporate the absolute ethanol to obtain the adhesive insoluble matter. The sum of the amount of filterable insoluble matter and the amount of adhesive insoluble matter is the amount of total insoluble matter, expressed in mg / 100ml.

[0034] The antioxidant effect of antioxidant in the present embodiment sees the following table:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com