Device for simulating land-based test of ship ballast water treatment system

A ship ballast water and treatment system technology, applied in the ship field, can solve the problems of large weather influence factors, high cost of rebuilding old ships, hidden safety hazards of experimenters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

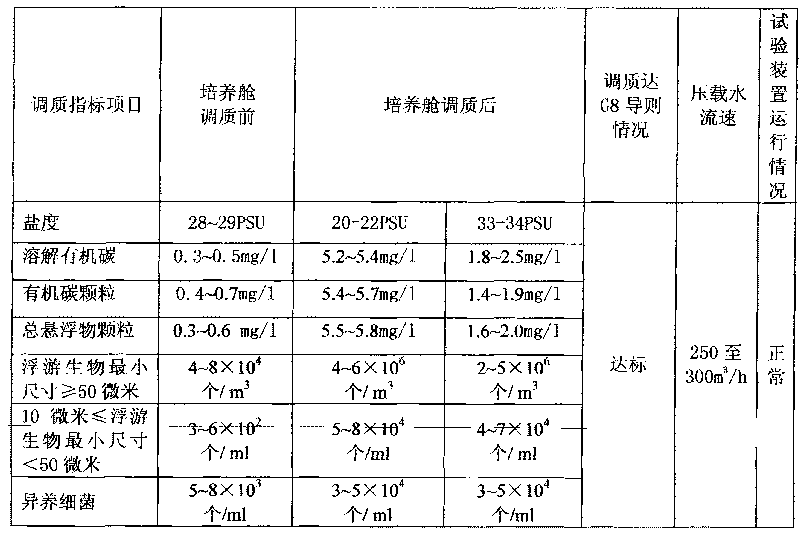

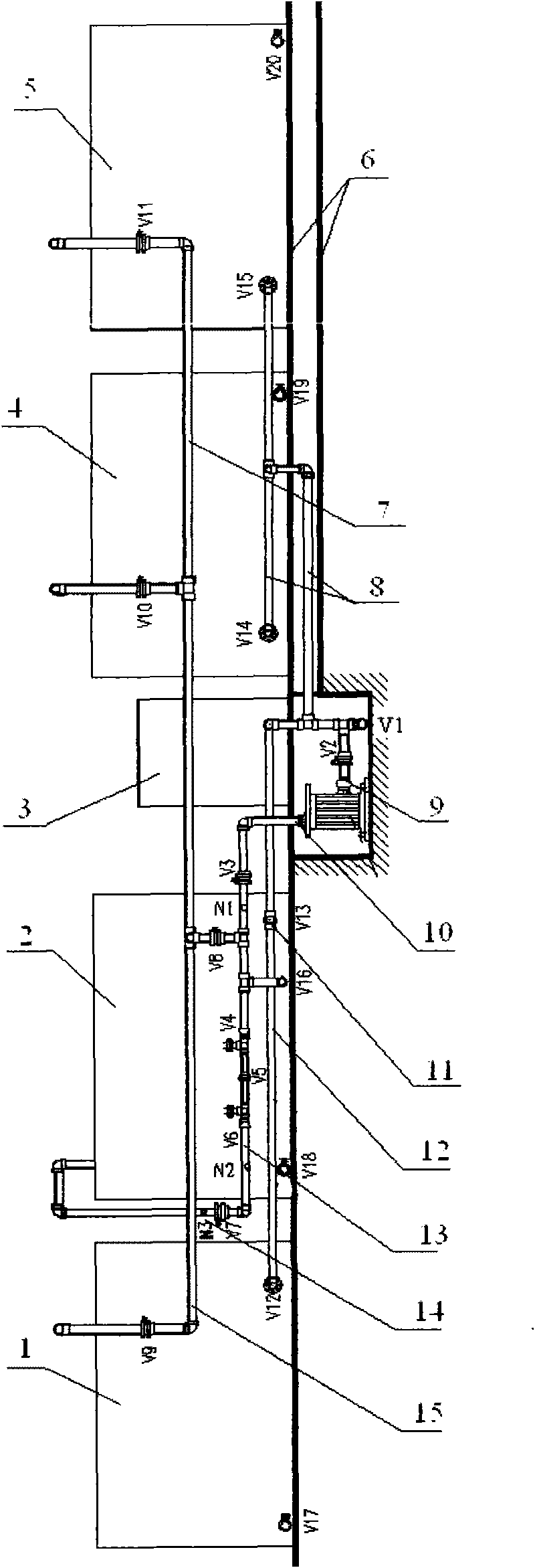

Embodiment 1

[0020] Embodiment 1: see image 3 , first add 600kg of sea salt, 10L of heterotrophic bacteria, green algae, 2kg of glucose-chitosan, and sea mud to 4-cultivation cabin 1 and 5-culture cabin 2, and the test salt water reaches the salinity of G8 guidelines > 32PSU, etc. The various index requirements, and with 250m 3The flow rate of / h injects the ballast water in the cultivation cabin from the ballast pump through the opened valves V2, V3, V4, V6,, V7, V14, V15 into the treatment cabin, through the opened valves V1, V2, V3, V8, V9 was injected into the comparison cabin, and samples were taken at N1, N2, and N3 respectively. After the ballast water was stored in the treatment cabin and the comparison cabin for 5 days, it was discharged with a pump, and samples were taken at N1. The samples obtained from the three places were tested for seawater parameters, microorganisms, plankton, active substances and related chemical substances and toxicity tests.

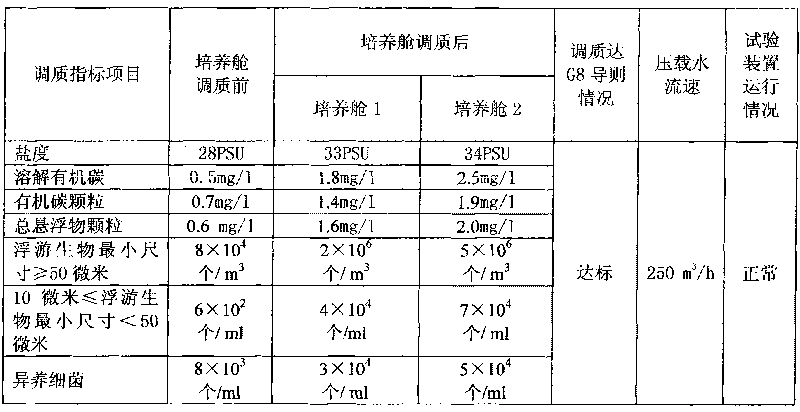

Embodiment 2

[0021] Embodiment 2: see Figure 4 First add 70m of tap water to 4-cultivation cabin 1 and 5-culture cabin 2 respectively 3 , heterotrophic bacteria 20L, green algae, glucose 0.5kg, chitosan 7kg, sea mud 20kg, the test salt water meets the requirements of various indicators such as salinity 3-32PSU in the G8 guideline, and the 300m 3 The flow rate of / h injects the ballast water in the cultivation cabin from the ballast pump through the opened valves V2, V3, V4, V6,, V7, V14, V15 into the treatment cabin, through the opened valves V1, V2, V3, V8, V9 was injected into the comparison cabin, and samples were taken at N1, N2, and N3 respectively. After the ballast water was stored in the treatment cabin and the comparison cabin for 5 days, it was discharged with a pump, and samples were taken at N1. The samples obtained from the three places were tested for seawater parameters, microorganisms, plankton, active substances and related chemical substances and toxicity tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com