Plate shape control method of hot rolling thin checkered plates

A plate shape control and pattern plate technology, applied in the field of steel rolling, can solve the problems of no involvement, and achieve the effect of improving high quality, considerable economic benefits, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Shougang Qiangang’s 2160mm hot-rolled wide-band steel production line was put into operation at the end of 2006, and began to produce hot-rolled checkered plates in early 2009. In the initial stage of checkered plate production, the main problems were:

[0052] 1) The thin specifications of checkered plates are mostly in the shape of medium waves during the rolling process, and the waves are relatively large;

[0053] 2) Since the support roll of the end frame adopts the CVC roll shape, there is a poor transition between the edge chamfer and the curve of the roll body, so the width specification of the checkered plate cannot be greater than 1600mm.

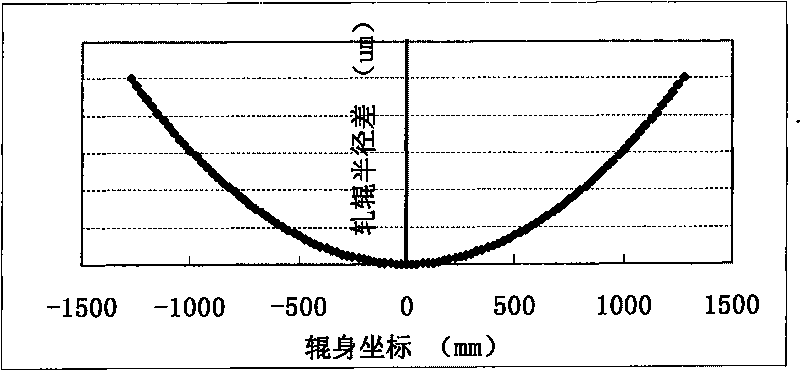

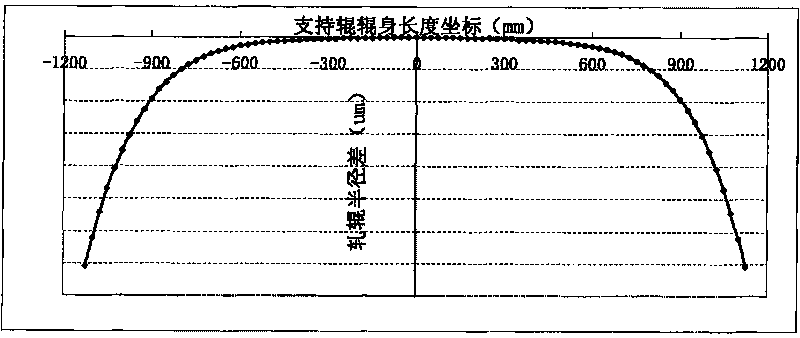

[0054] The plate shape data of the rolled checkered plate with a thickness less than or equal to 2.5mm was counted, and the results are as follows Figure 4 , Figure 5 , Image 6 and Figure 7 shown. Since the flatness testing instrument on the 2160mm hot rolling production line of Shougang Qiangang adopts the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com