Preparation method of asparagus leaf instant tea

A technology of instant tea and asparagus, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of asparagus leaf rot, waste of resources, environmental pollution, etc., and achieve the effects of convenient drinking, low product cost, and easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

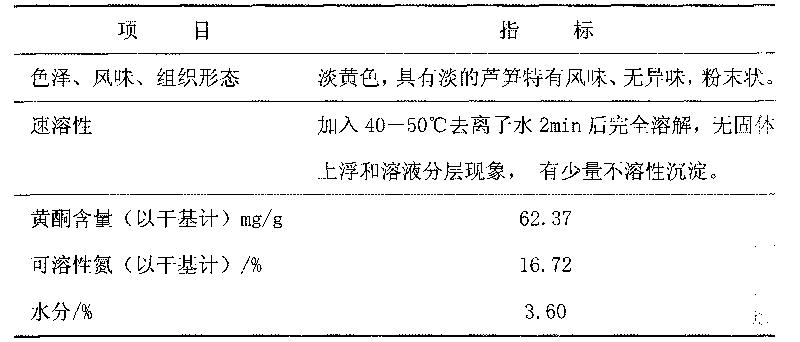

Embodiment 1

[0034] Weigh fresh asparagus leaves and place them in a microwave oven with a power of 800w for 60 seconds to inactivate the enzyme; crush the asparagus leaves, commercially available green tea and licorice to 60-80 meshes after inactivating the enzymes, and mix the asparagus leaves and green tea in a weight ratio of 7:3 Compared with compounding, on the basis of this ratio, adding 20% licorice by weight. The above-mentioned asparagus tea is prepared into a solution with a concentration of 5%, and the neutral protease (enzyme activity is 1000AU / kg) provided by Novozymes (China) Biotechnology Co., Ltd. and the cellulose provided by Ningxia Hersbit Biotechnology Co., Ltd. Enzyme (2000U / mL), the process conditions are: the ratio of cellulase and neutral protease is 2:1, the addition amount is 8U / g and 4AU / kg respectively, the reaction time is 40 minutes, and it is spray-dried. Determination of flavonoids, soluble nitrogen, ash and other indicators of asparagus leaf instant tea ...

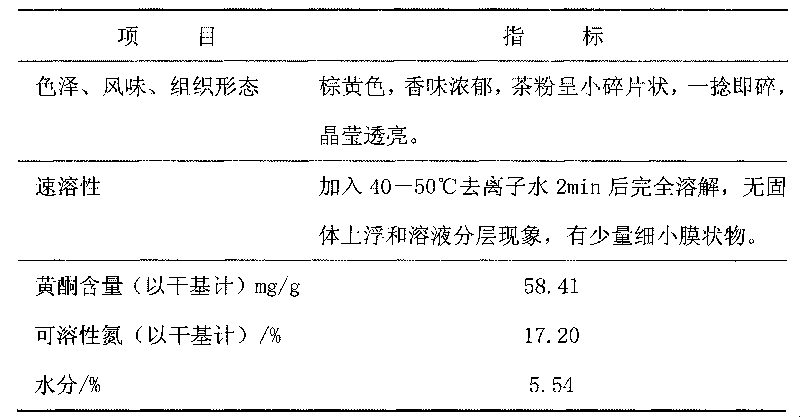

Embodiment 2

[0038] Weigh fresh asparagus leaves and place them in a microwave oven with a power of 800w for 60 seconds to inactivate the enzyme; crush the asparagus leaves, commercially available green tea and licorice to 60-80 meshes after inactivating the enzymes, and mix the asparagus leaves and green tea in a weight ratio of 7:3 Compared with compounding, on the basis of this ratio, adding 20% licorice by weight. The above-mentioned asparagus tea is prepared into a solution with a concentration of 5%, and the neutral protease (enzyme activity is 1000AU / kg) provided by Novozymes (China) Biotechnology Co., Ltd. and the cellulose provided by Ningxia Hersbit Biotechnology Co., Ltd. Enzyme (2000IU / mL), the process conditions are: cellulase and neutral protease addition ratio is 2:1, the addition amount is respectively 8U / g and 4AU / kg, reaction time is 40 minutes, vacuum drying. Determination of flavonoids, soluble nitrogen, ash and other indicators of asparagus instant tea products are s...

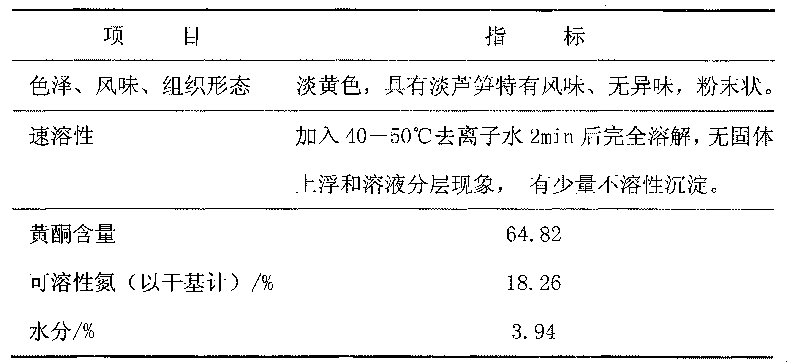

Embodiment 3

[0042] Weigh fresh asparagus leaves and place them in a microwave oven with a power of 800w for 60 seconds to inactivate the enzyme; crush the asparagus leaves, commercially available green tea and licorice to 60-80 meshes after inactivating the enzymes, and mix the asparagus leaves and green tea in a weight ratio of 7:3 Compared with compounding, on the basis of this ratio, adding 20% licorice by weight. The above-mentioned asparagus tea is prepared into a solution with a concentration of 10%, and the neutral protease (enzyme activity is 1000AU / kg) provided by Novozymes (China) Biotechnology Co., Ltd. and the cellulose provided by Ningxia Hersbit Biotechnology Co., Ltd. Enzyme (2000IU / mL), the process conditions are: cellulase and neutral protease are added at a ratio of 2:1, the addition amounts are 16U / g and 8AU / kg respectively, the reaction time is 60 minutes, and spray-dried. Determination of flavonoids, soluble nitrogen, ash and other indicators of asparagus instant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com