Test unit for monitoring oil-paper insulation state

A test device, oil-paper insulation technology, applied in the direction of testing the dielectric strength, etc., can solve the problems of complex operation, destructiveness of the tested product, expensive test equipment, and less information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further describe in detail below in conjunction with accompanying drawing;

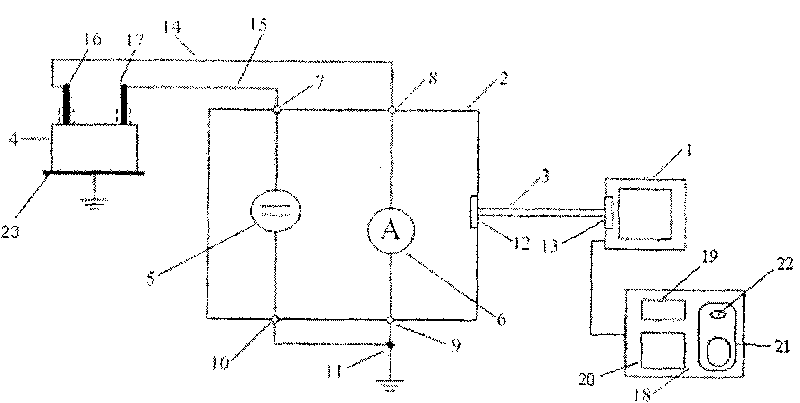

[0019] A test device for monitoring the state of oil-paper insulation, as attached figure 1 As shown, it includes computer 1, electrometer 2, control bus communication cable 3, the GPIB control card is installed in the PCI slot of the computer, and the GPIB communication cable 3 is connected to the GPIB interface 12 of the electrometer 2 and the PCI slot inserted in the computer 1. The interface 13 of the GPIB control card in the slot, the high-voltage DC power supply 5 and the ammeter 6 are arranged in the electrometer 2, and one end of the control bus communication cable 3 is connected to the control bus interface 12 of the electrometer 2, and the other end is connected to the control bus control in the computer 1. The interface 13 of the card, the low-voltage terminal interface 10 of the high-voltage DC power supply 5 and the grounding interface 9 of the electrometer 2 are jointly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com