Improved process for the oxidative dehydrogenation of ethane

A carbon monoxide and carbon dioxide technology, applied in chemical instruments and methods, carbon monoxide, carbon monoxide reaction preparation, etc., can solve the problems of high cost and expensive ethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

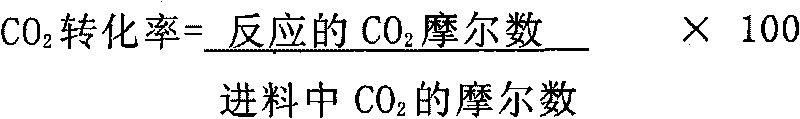

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Preparation of potassium-manganese oxide catalyst

[0021] The OMS catalyst was prepared using the following steps: In a separate container, 16.8 g of MnSO 4 ·H 2 O and 6 mL concentrated HNO 3 Dissolved in 60 ml of distilled water, 11.8 g of KMnO 4 Dissolve in 200 ml distilled water. Then, the KMnO 4 The solution was added dropwise to MnSO 4 In solution, a light brown colloidal suspension was produced. The colloidal suspension was refluxed at 100°C for 12 hours. The product formed was filtered and washed with deionized water to remove unwanted reaction by-products. Finally, the material was dried in an oven at 120°C for 6-12 hours.

[0022] Place the synthesized K-OMS-2 in a tube furnace at 800 °C at a flow rate of 500 cm 3 / min of nitrogen for 2 hours. The formed material was used as a carrier material. The Fe-loaded catalyst was obtained by impregnating 1.5 g of the support material in 1.06 g of 1M Fe(NO 3 ) 3 .9H 2 O aqueous solution, and shake on a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com