Cutter frame regulating mechanism of three-surface trimmer

A technology of adjusting mechanism and tool holder, which is applied in metal processing and other directions, can solve the problems of low reliability, large length error, large impact force, etc., and achieve the effect of high reliability, easy opening or fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

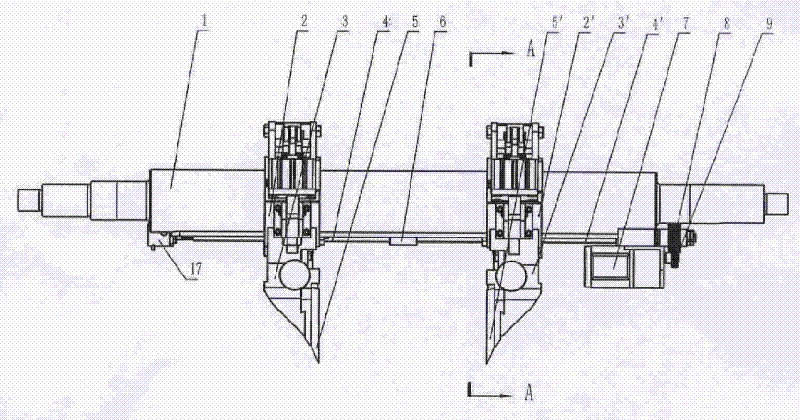

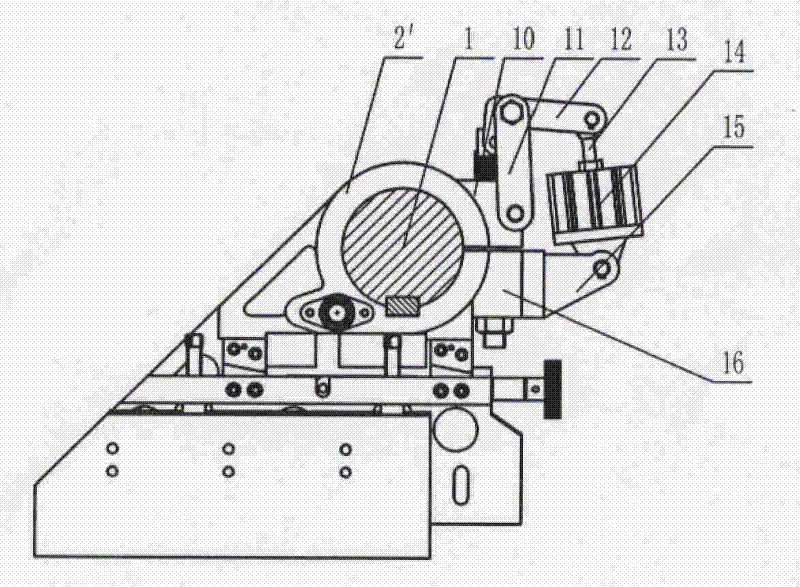

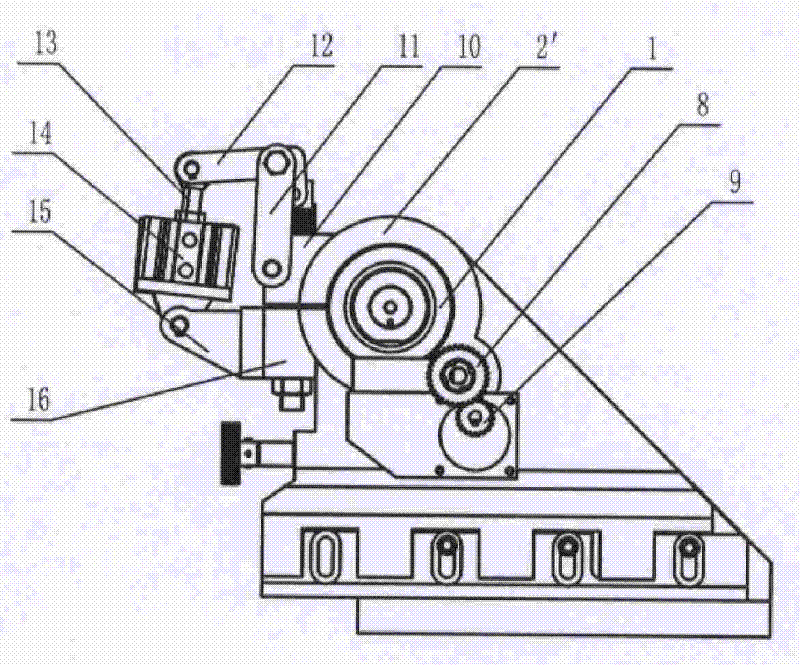

[0017] Referring to the accompanying drawings, the knife rest adjustment mechanism of this three-side shredder includes a main shaft 1, a knife rest 3, 3' and a set of reeds, and the knife rests 3, 3' are respectively fixed with cutting knives 5, 5', The set of reeds has a left set of reeds 2 and a right set of reeds 2', the left and right sets of reeds 2, 2' are set on the main shaft 1, and the left and right set of reeds 2, 2, ' are respectively connected with the tool holders 3, 3 'Fixed connection, the left screw 4 is screwed on the left reed 2, the right screw 4' is screwed on the right reed 2', and the left screw 4 and the right screw 4' are connected through the screw connecting sleeve 6 connected, and the screw direction of the left screw 4 is opposite to that of the right screw 4', the driven gear 8 is fixedly sleeved on the right screw 4', and the driving gear 9 is installed on the rotating shaft on the reduction motor 7, and the driving gear 9 and The driven gear 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com