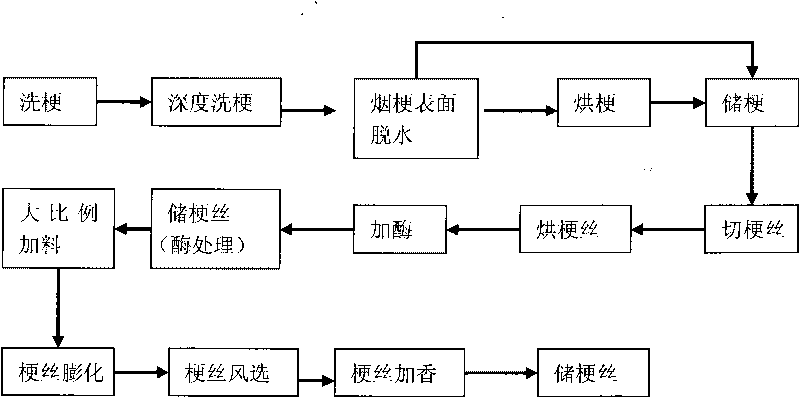

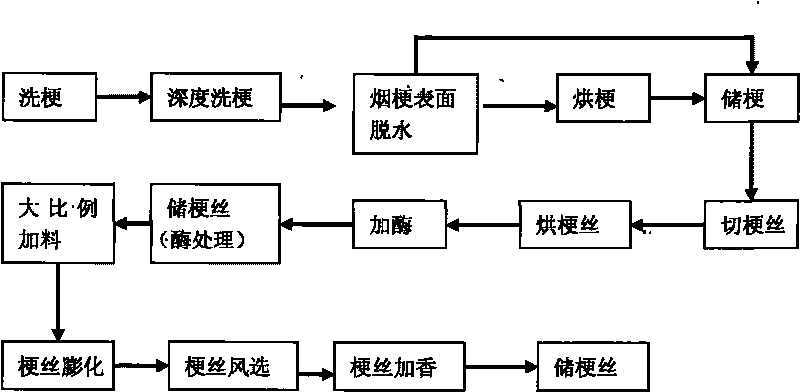

Process for biochemically treating cut stems

A technology of biochemical treatment and shredded stems, which is applied in the treatment of tobacco, tobacco, food science, etc., can solve the problems of unfavorable high-end products, reduced cost of leaf group formula, increased cost, etc., so as to increase the scope and proportion of use, improve taste, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The incoming tobacco stems (moisture content 12.5%) are quickly washed by the stem washing machine for 2 seconds to wash away the dust and silt on the surface of the tobacco stems. After the moisture content of the tobacco stems increases to 22%, enter the spiral ultrasonic stem washing machine for Deep stem washing, water temperature 20°C, solid-liquid ratio 1:20, washing time 1min, chloride ions, nitrates and some water-soluble substances in the tobacco stems are washed out, so that the moisture content of the tobacco stems increases to 42%; The material centrifuge removes the moisture on the surface of the tobacco stems. While dehydrating, the moisture accelerates to penetrate into the interior of the tobacco stems and accelerates the softening of the tobacco stems; the dehydrated tobacco stems enter the vibrating fluidized bed and are dried to reduce the moisture to 28%. Then enter the shredded stem machine; cut the stems through the shredded stem machine; after the ...

Embodiment 2

[0025] The incoming tobacco stems (moisture content 12.5%) are quickly washed by the stem washing machine for 8 seconds to wash away the dust and sediment on the surface of the tobacco stems, and after the moisture content of the tobacco stems increases to 26%, enter the spiral ultrasonic stem washing Machine for deep stem washing, water temperature 80°C, solid-to-liquid ratio 1:4, washing time 5min, chloride ions, nitrates and some water-soluble substances in the tobacco stems are washed out, and the moisture content of the tobacco stems is increased to 50%. The continuous discharge centrifuge removes the moisture on the surface of the tobacco stems. While dehydrating, the moisture accelerates to penetrate into the interior of the tobacco stems and accelerates the softening of the tobacco stems; the dehydrated tobacco stems enter the vibrating fluidized bed for drying to reduce the moisture to After 34%, it enters the stem cutting machine; the stems are cut by the stem cutting...

Embodiment 3

[0027]The incoming tobacco stems (moisture content 12.5%) are quickly washed by the stem washing machine for 6 seconds to wash away the dust and sediment on the surface of the tobacco stems and increase the moisture content of the tobacco stems to 24%, then enter the spiral ultrasonic stem washing Machine for deep stem washing, water temperature 60°C, solid-liquid ratio 1:10, washing time 2min, chloride ions, nitrates and some water-soluble substances in the tobacco stems are washed out, so that the moisture content of the tobacco stems increases to 45%; Squeeze and extrude the tobacco stems with screw to remove moisture from the surface of the tobacco stems. While dehydrating, the moisture accelerates to permeate into the interior of the tobacco stems and accelerates the softening of the tobacco stems; the dehydrated tobacco stems enter the vibrating fluidized bed and are dried to make After the moisture drops to 30%, it enters the stem cutting machine; through the stem cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com