Fuel cell system and method of generating electricity and reducing heavy metal through sewage treatment

A technology for fuel cell systems and sewage treatment, which is applied in the fields of fuel cell systems, sewage treatment, power generation and heavy metal reduction, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

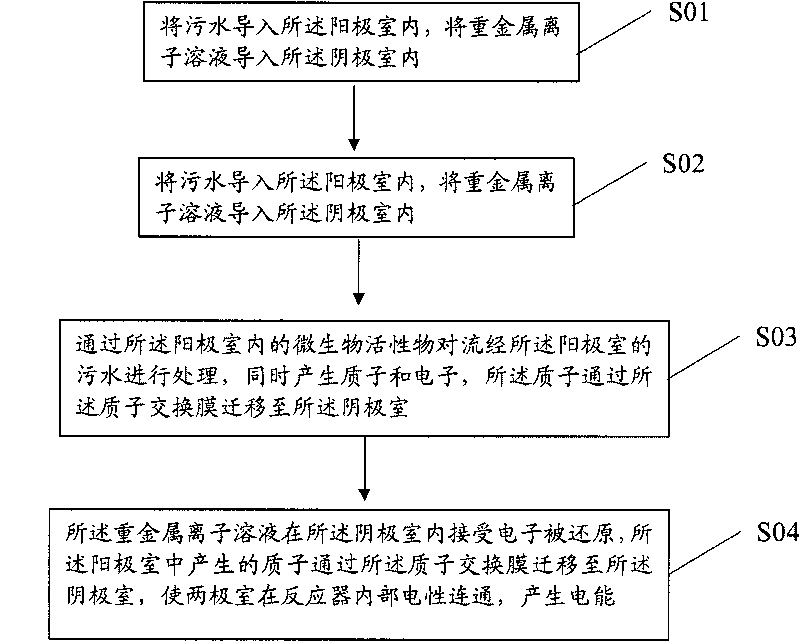

Method used

Image

Examples

Embodiment 1

[0041] Example 1 (M2)

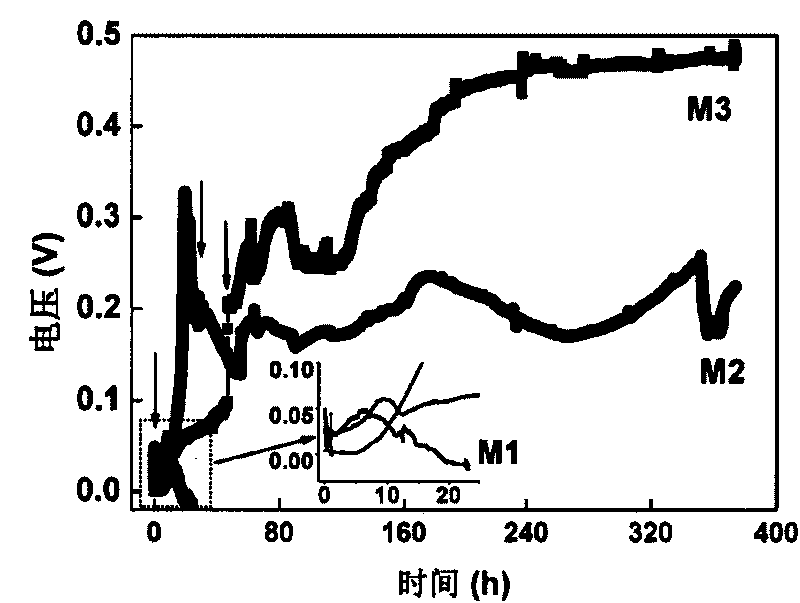

[0042] After adding 900ml of glucose simulated waste water and strain mixed solution in the anode chamber 14, add 900ml of phosphate buffer (pH=6.8) into the cathode chamber 13 earlier and expose to oxygen, after running for 24 hours, the buffer solution is replaced with 0.1mol / L copper sulfate solution. Then, operate according to the above steps S03-S04. During operation, the MFC output voltage is measured as a function of time, obtained as image 3 The circular icon curve shown in , the arrow indicates the time point of adding copper sulfate solution to the cathode chamber.

Embodiment 2

[0043] Example 2 (M3)

[0044] After adding 900ml of glucose simulated wastewater and strain mixture to the anode chamber 14, first add 900ml of phosphate buffer (pH=6.8) to the cathode chamber 13 without aeration, and then change the buffer solution to 0.1 after 48 hours of operation. mol / L copper sulfate solution. Then, operate according to the above steps S03-S04. During operation, the MFC output voltage is measured as a function of time, obtained as image 3 The square icon curve shown in , the arrow indicates the time point of adding copper sulfate solution to the cathode chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com