Water leakage simulating and measuring system of tunnel in centrifugal field

A measurement system and leakage water technology, which is applied in the direction of measuring the growth and deceleration rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of unrealistic, difficult to obtain soil parameters, and result deviations, etc. , to achieve the effects of convenient production, shortened research time, and reduced disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

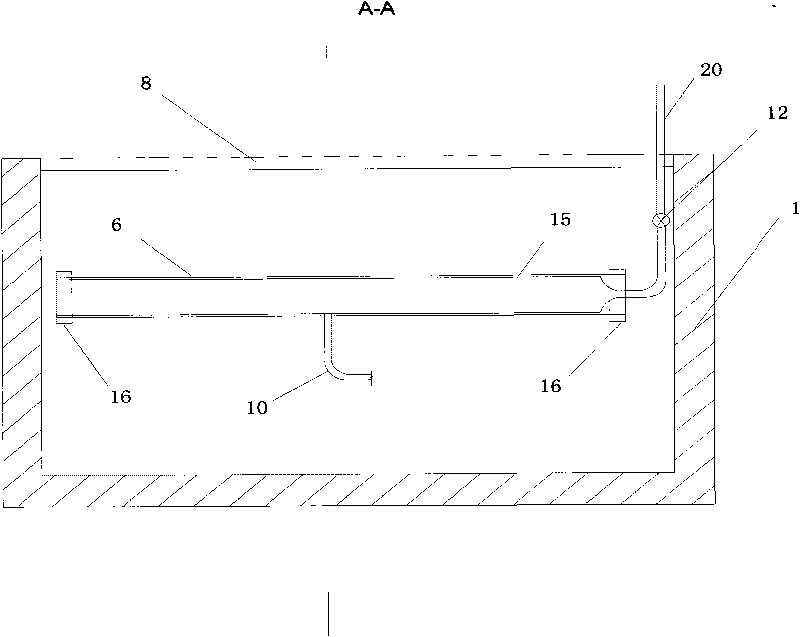

[0022] Embodiment 1: as figure 1 with figure 2 As shown, the shape of the model box 1 is a cuboid, the net size is 800×500×500mm (length×width×height), and it is composed of 6 side joints. The front side is a 30mm thick plexiglass surface 2, the plexiglass surface 2 is convenient for labeling and taking pictures, the other sides are 30mm thick hard alloy aluminum plates, the inside of the model box 1 is 350mm away from the side, and an aluminum alloy partition is placed parallel to the side. The plate 3 has a thickness of 30 mm. The partition 3 separates the model box 1 into a model side and an accessory side. Filling soil can be placed on the model side, and a sealing top cover 8 is placed on the top of the model side. The sealing top cover 8 can be made of tempered glass. The size is 450×500×500mm (length×width×height).

[0023] Such as image 3 with Figure 4 As shown, the partition plate 3 is welded by a rectangular steel plate 17, two longitudinal ribs 18 and a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com