Permanent magnet track brake

A magnetic track brake and permanent magnet technology, which is applied to the brakes where the braking element interacts with the track, asynchronous inductive clutches/brakes, railway braking systems, etc. , permanent magnet demagnetization and other problems, to achieve the effect of improving braking effect, avoiding wear and reducing braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

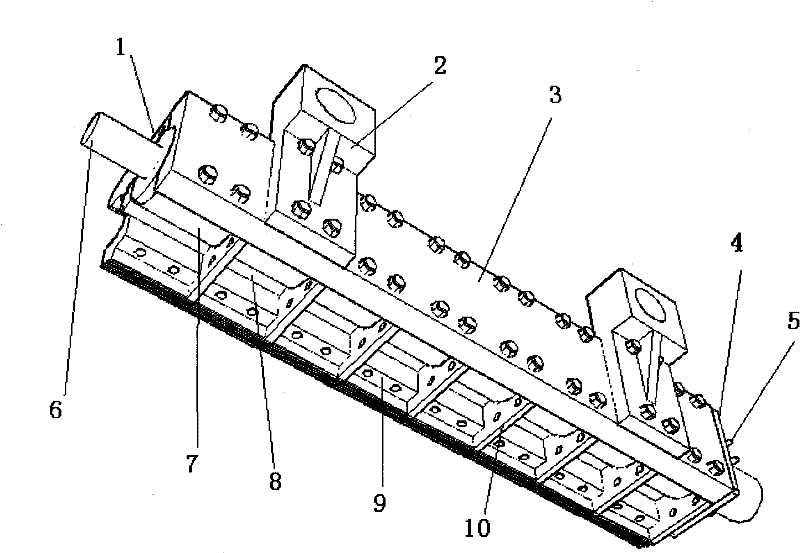

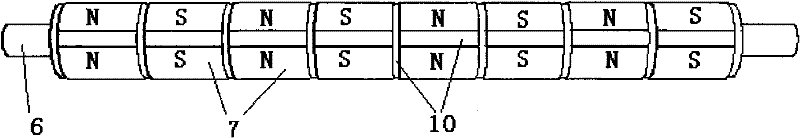

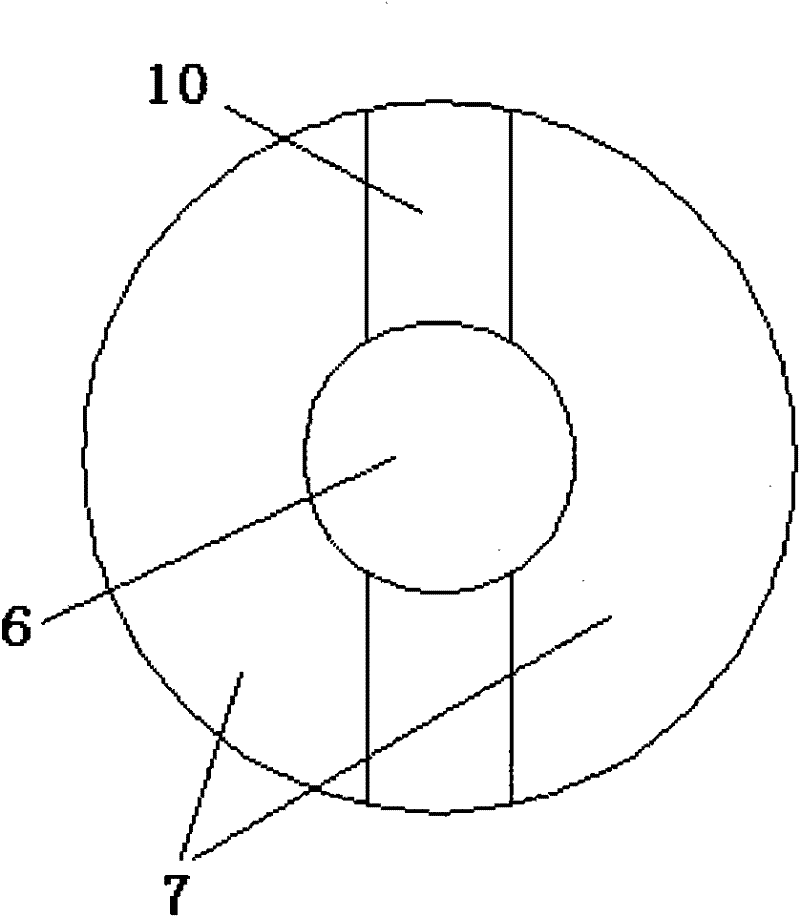

[0016] like Figure 1-3 As shown, the permanent magnet track brake has a permanent magnet shaft 6, and an even number of permanent magnets 7 are arranged on the outer ring of the permanent magnet shaft 6. The N poles and S poles of the magnets 7 are arranged at intervals with opposite polarities along the axial direction of the permanent magnet shaft 6 and alternately in sequence, and the permanent magnets 7 with the same polarity are arranged symmetrically at intervals along the central axis of the permanent magnet shaft 6 . A separator 10 is provided at the transverse and longitudinal gaps between the N pole and the S pole of the permanent magnet 7 . The separator 10 is made of a non-magnetic material and is in close contact with the permanent magnet 7 . The cross section of the spacer 10 is combined with the cross section of the permanent magnet 7 to be circular.

[0017] The bracket structure of the brake is composed of the upper top cover 3, the end covers 4 at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com