Soil water potential sensor

A soil water potential and sensor technology, applied in instruments, soil material testing, measuring devices, etc., can solve problems such as low response sensitivity, and achieve the effect of convenient exhaust and low exhaust frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

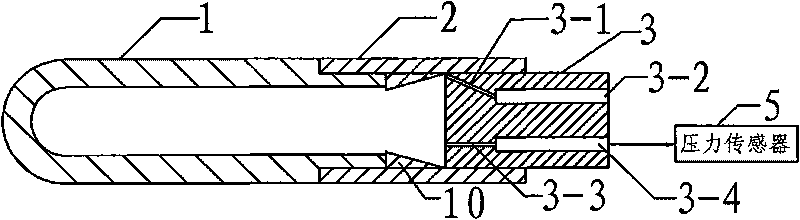

[0008] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, a soil water potential sensor, which includes a pressure sensor 5, and it also includes a clay head 1, an air collection chamber casing 2 and a pipe plug 3; the cross-sectional shape of the clay head 1 is U-shaped, and the clay head The inner cavity of 1 is a gas collection chamber, one end of the gas collection chamber casing 2 is sealed and fixed at the opening of the clay head 1, and the other end of the gas collection chamber casing 2 is sealed and fixed with a pipe plug 3, and the pipe plug 3 There is an air guide channel and a water inlet channel on the top, and the air guide channel and the water inlet channel are both connected to the gas collection chamber, and the pressure signal input end of the pressure sensor 5 is set at the water inlet hole of the water inlet channel of the pipe plug 3.

[0009] There are two main sources of air bubbles in the air collection chamber. ...

specific Embodiment approach 2

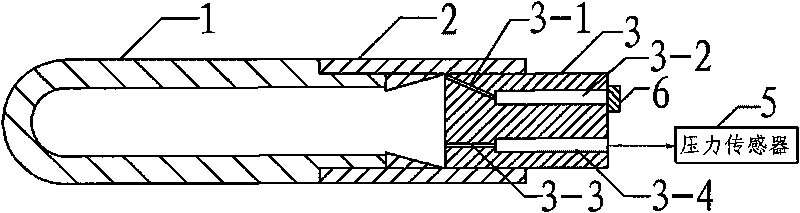

[0019] Embodiment 2. The difference between this embodiment and the soil water potential sensor described in Embodiment 1 is that the air guide channel is composed of a first air guide tube 3-1 and a second air guide tube 3-2. One end of the first air guide tube 3-1 communicates with the gas collection chamber, the other end of the first air guide tube 3-1 communicates with one end of the second air guide tube 3-2, and the other end of the second air guide tube 3-2 It is the air guide hole of the pipe plug 3 , and the port connecting the first air guide pipe 3 - 1 with the air collection chamber is located at the inner wall of the clay head 1 .

[0020] In this embodiment, a certain angle is set between the first air guide tube 3-1 and the second air guide tube 3-2, and the opening of the first air guide tube 3-1 is close to the inner wall of the clay head 1. This method can Prevent water from the air collection chamber from entering the air channel.

specific Embodiment approach 3

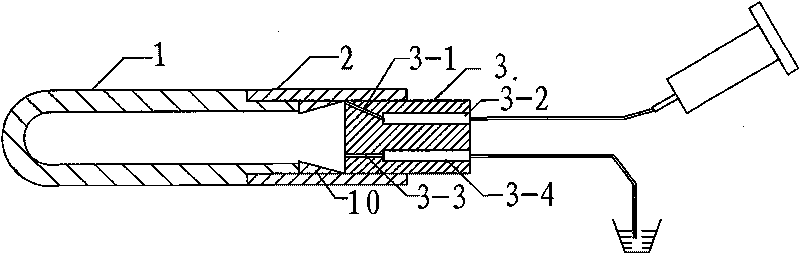

[0021] Embodiment 3. The difference between this embodiment and the soil water potential sensor described in Embodiment 1 or 2 is that the gas collection chamber casing 2 also includes an annular prism 10, and the ring prism 10 The side is integrally connected with the casing 2 of the gas collection chamber; the large end of the annular prism 10 is fixed on the end face of the opening of the clay head 1 , and the small end of the annular prism 10 is located on the side of the pipe plug 3 .

[0022] In this embodiment, the first air guide tube 3-1 is located at the upper end of the open ring-shaped prism 10, and this way can maximize the air in the air collection chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com