Double universal joint pin cardan joint

A cross shaft and universal joint technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of cross shaft offset, occupation, impact, etc., to improve structural strength, reduce additional stress, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

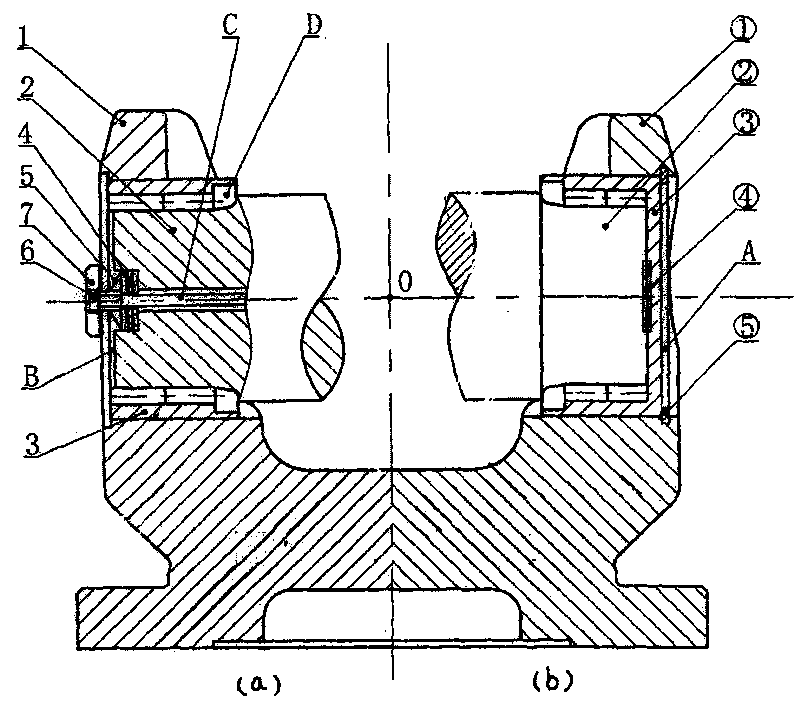

[0018] see figure 1 (a), a double cross shaft universal joint, including a flange yoke 1, a cross shaft 2, a bearing 3, a cross screw 6 and a nut 7 to connect the two forks of the flange yoke 1 into one, that is, the flange yoke The head 1, the bearing 3, the cross screw 6 and the nut 7 are connected into one body to form a closed fork head. There is a floating gap B between the cross shaft 2 and the bearing 3. The two ends of the cross screw 6 are provided with a plane bearing 4 and a stack spring 5. The hollow C of the cross shaft 2 only accounts for 7%-8% of the cross section of the cross shaft 2. A peristaltic lubrication system is provided in the hollow C of the cross shaft 2, and an application seal is provided in the gap D next to the bearing 3.

[0019] see figure 1 (a), the seal is a TC-type seal with skeleton double lips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com