Underwater vertical oil-gas multiphase pump for offshore production wells

An offshore oil field, phase-mixing technology, applied in the components of pumping devices for elastic fluids, non-variable-capacity pumps, non-displacement pumps, etc., can solve the complex installation process, difficult positioning, large footprint, etc. problems, to achieve the effect of simple installation process, reasonable space layout and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

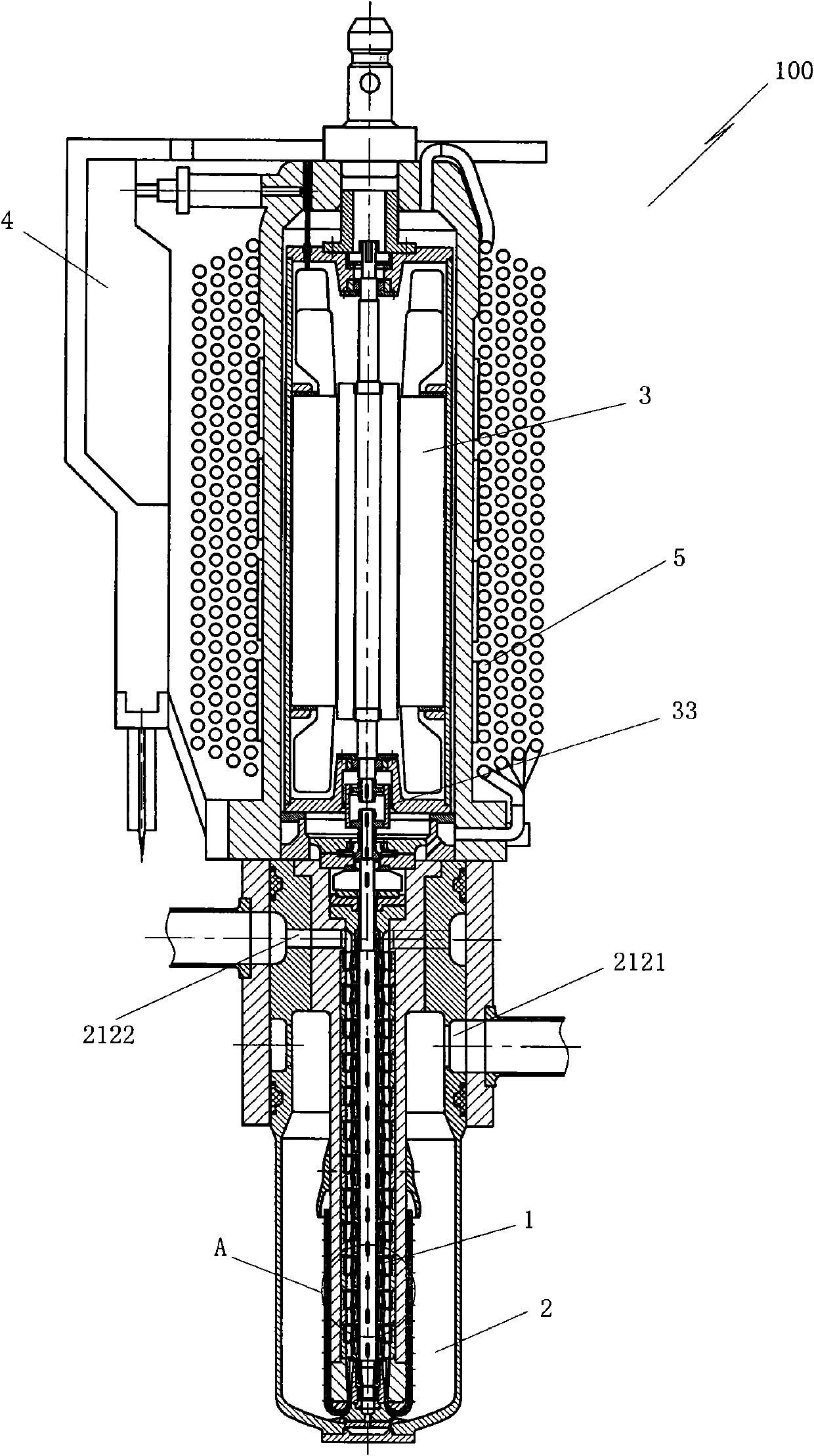

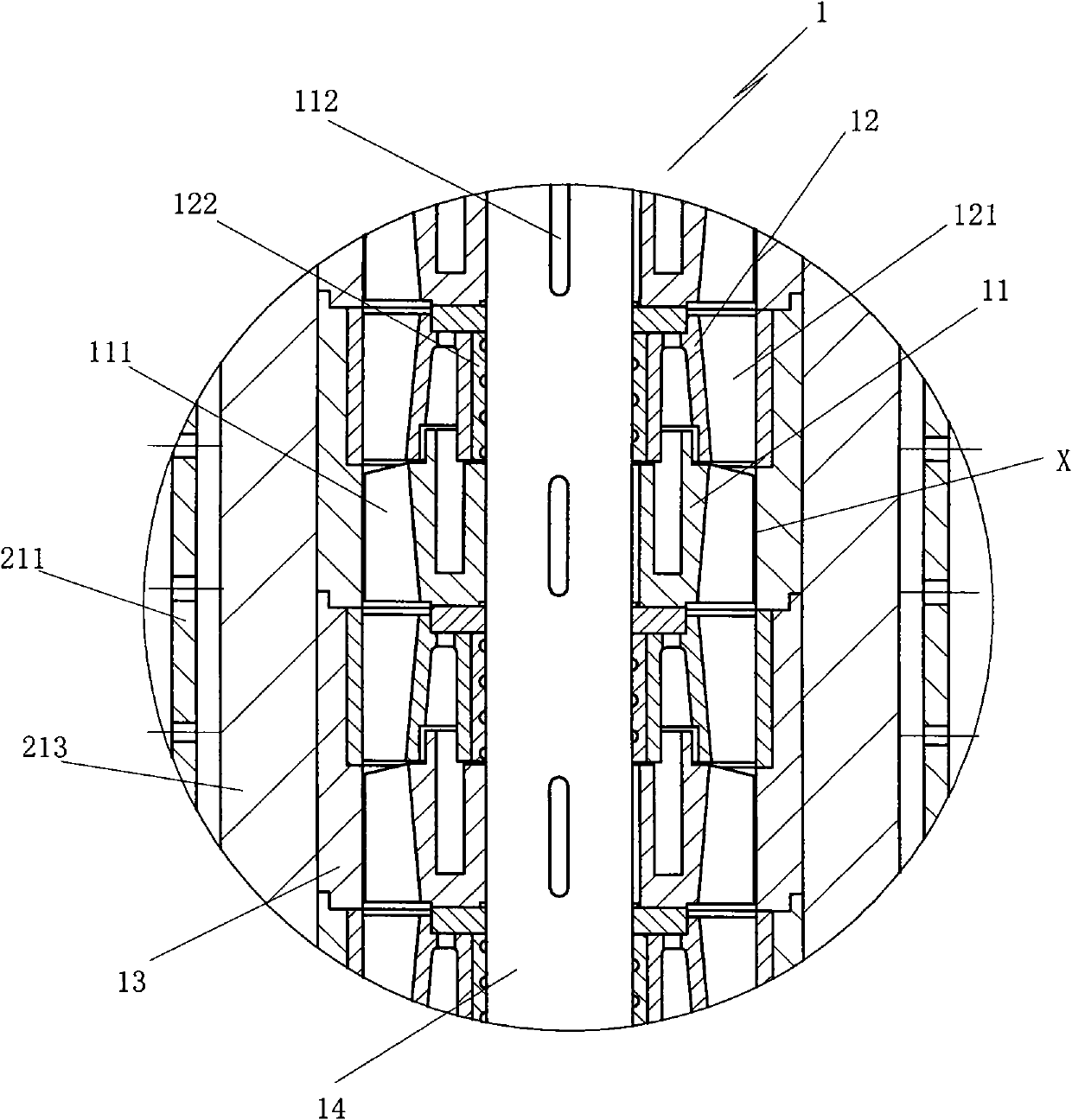

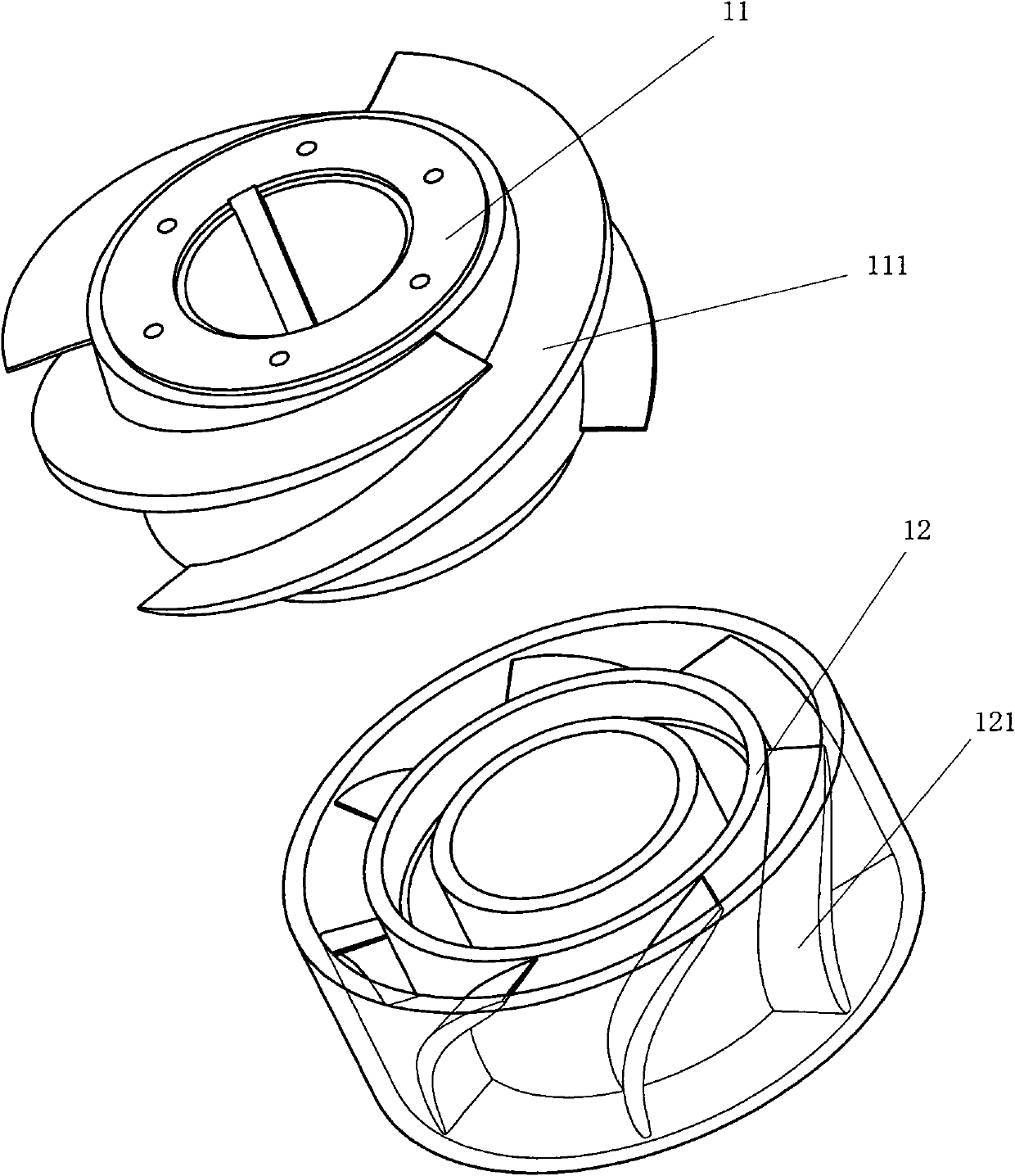

[0041] Such as figure 1 As shown, the present invention proposes an underwater vertical oil-gas multiphase mixed transportation pump 100 for offshore oil fields. The multiphase mixed transportation pump 100 at least includes a multiphase booster device 1, a multiphase fluid pretreatment device 2, Power device 3, measurement and control device 4, and circulating cooling and lubricating device 5; the multiphase fluid pretreatment device 2 is vertically arranged at the lower position of the entire oil-gas multiphase mixed delivery pump 100, inside the multiphase fluid pretreatment device 2 The multi-phase supercharging device 1 is vertically arranged at the central position, and a power unit 3 is connected above the multi-phase supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com