Reciprocating compressed-air power engine

A compressed air and aerodynamic technology, applied in the field of mechanical equipment, can solve problems such as wasting time, cumbersome operation, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

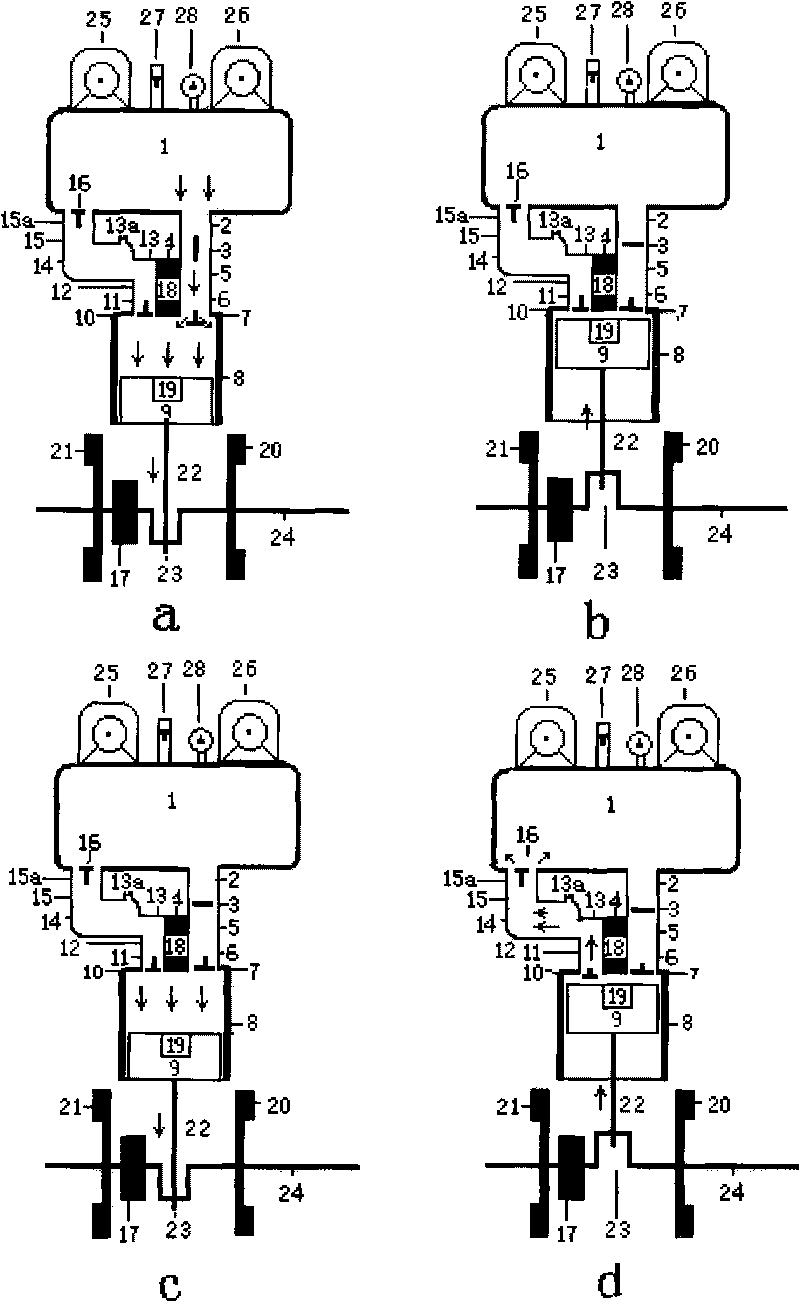

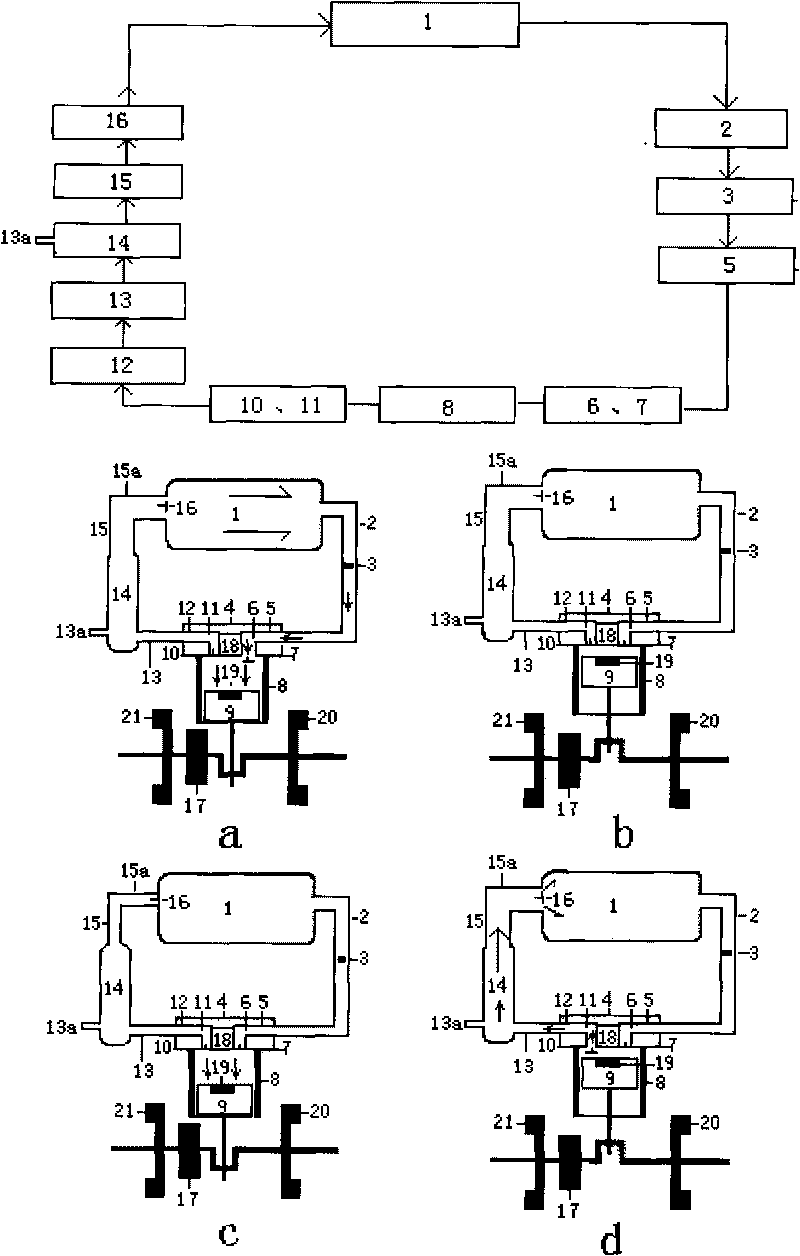

Embodiment Construction

[0098] 1. Engine structural features (three parts);

[0099] The first part; the composition of the aerodynamic cycle structure;

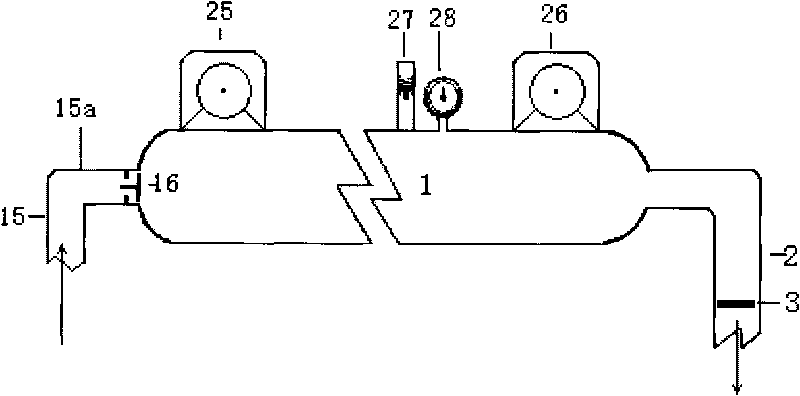

[0100] By two ends semi-circular, cylindrical or square compressed air storage tank 1, it is installed on its tank; Inflatable air compressor 25, supplementary air compressor 26, pressure safety valve 27, barometer 28, such as figure 1 , image 3 The gas storage tank gas transmission conduit 2 interface and the return gas transmission conduit 15a interface are designed on the tank body or at both ends of the tank, and its structural composition is connected with the gas storage tank, according to the aerodynamic flow direction figure 2 , the working gas of the engine can be divided into three structural connection modes: air supply, start-up exhaust, and return gas;

[0101] 1. Gas supply structure connection; it is composed of gas storage tank gas delivery conduit 2, electronically controlled gas flow regulating valve 3, air inlet 5 on cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com