Multi-loading point coal flow control system

A control system and loading point technology, which is applied in transportation and packaging, earthwork drilling, underground transportation, etc., can solve the problems of uncontrollable coal discharge of the discharge funnel, affecting the production order, crushing the transportation tape, etc., to achieve control coordination Safety, reduce the accident rate, ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

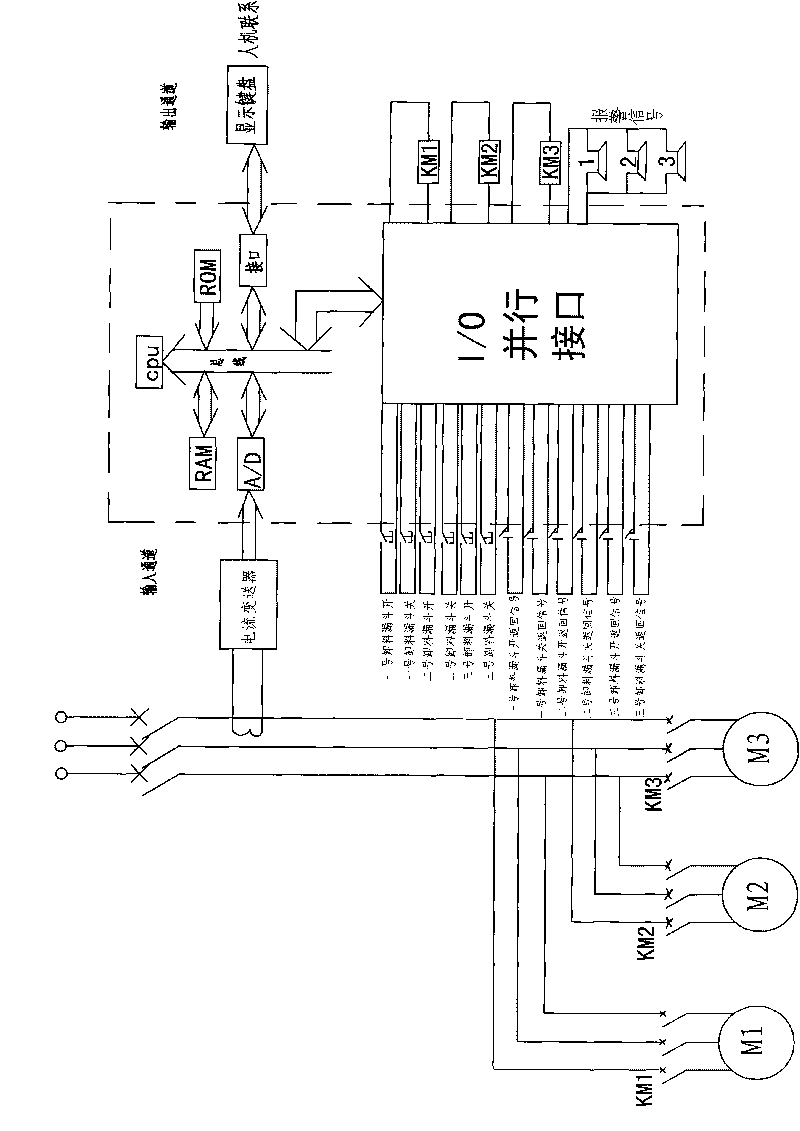

[0014] Embodiment 1 automatic control

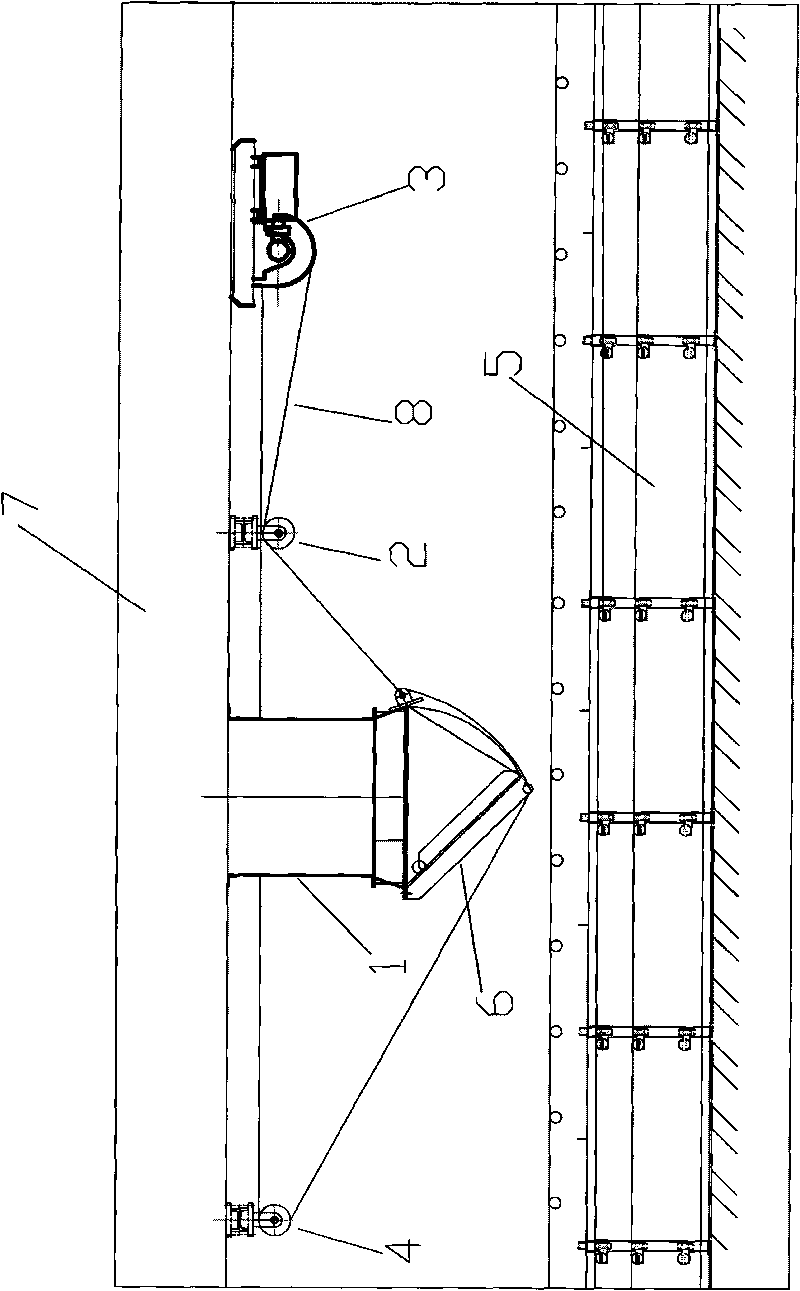

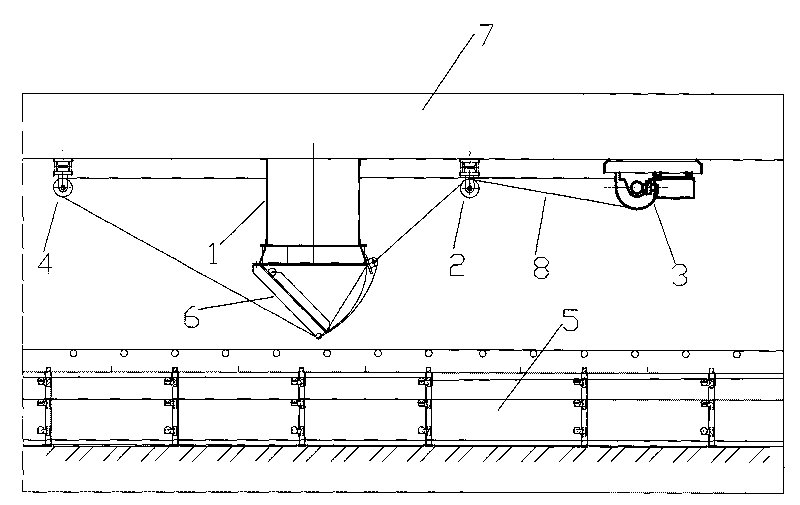

[0015] The multi-loading point coal flow control system of the present invention comprises a discharge hopper 1 and a switch drive device for the discharge hopper mouth; a fan-shaped door 6 is hinged at the opening of the bottom of the discharge hopper 1, and a discharge hopper opening and discharging are installed on the fan-shaped door. The two travel switches are closed by the funnel, and the travel switch adopts a contactor; the driving device of the discharge funnel opening switch includes a reverse-rotating drum winch 3 and two fixed pulleys installed on the top plate 7 of the belt lane, and the arrangement sequence is reverse-rotating drum Winch 3, right fixed pulley 2, discharge funnel 1, left fixed pulley 4, steel wire rope 8 is wound on the drum winch, one end of the steel wire rope is fixed on the free end of the fan-shaped door 6 after going through the right fixed pulley 2, and the other end passes through the right fixed pul...

Embodiment 2

[0018] Embodiment 2 manual control

[0019] The multi-loading point coal flow control system of the present invention comprises a discharge hopper 1 and a switch drive device for the discharge hopper mouth; a fan-shaped door 6 is hinged at the opening of the bottom of the discharge hopper 1, and a discharge hopper opening and discharging are installed on the fan-shaped door. The two travel switches are closed by the funnel, and the travel switch adopts a contactor; the driving device of the discharge funnel opening switch includes a reverse-rotating drum winch 3 and two fixed pulleys installed on the top plate 7 of the belt lane, and the arrangement sequence is reverse-rotating drum Winch 3, right fixed pulley 2, discharge funnel 1, left fixed pulley 4, steel wire rope 8 is wound on the drum winch, one end of the steel wire rope is fixed on the free end of the fan-shaped door 6 after going through the right fixed pulley 2, and the other end passes through the right fixed pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com