Automatic valve locking device and control method thereof

An automatic locking and gate technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems affecting the passage capacity and operation safety of ship locks, the speed of gate movement cannot be controlled, and the positioning precision is low, so as to achieve accurate locking action , simple structure and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

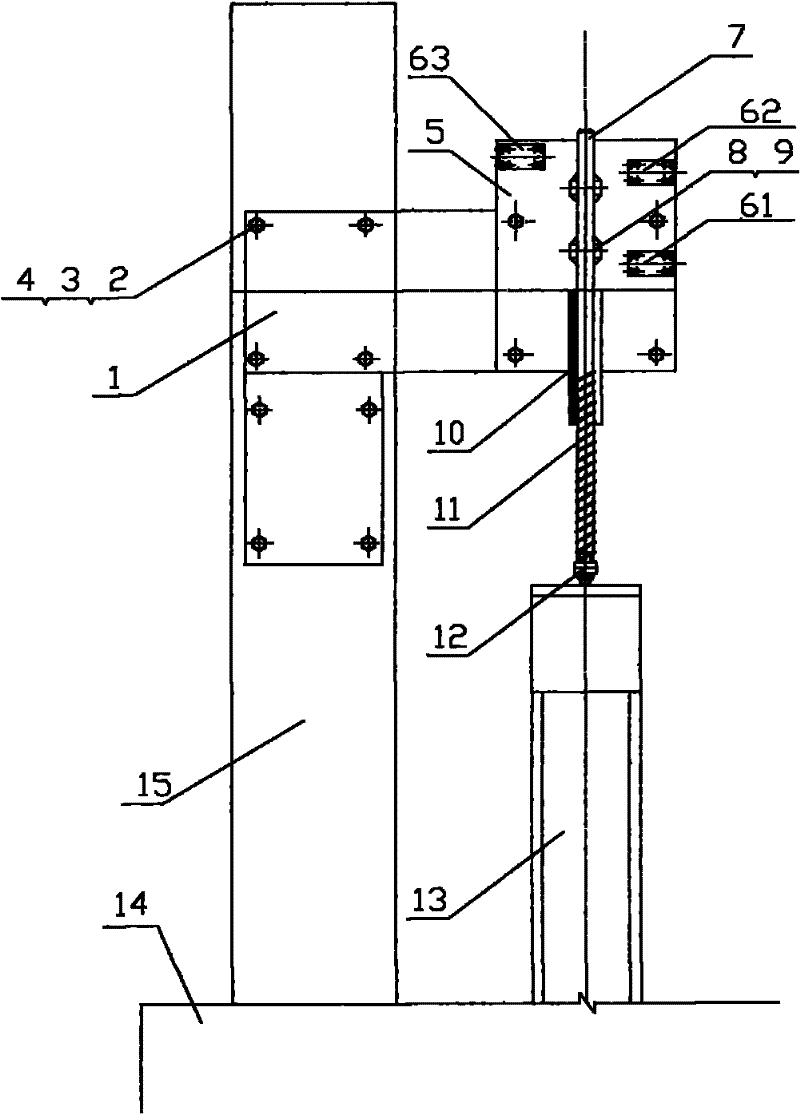

[0017] See figure 1 , The present invention installs one set on the left and right sides of the gate body, each set includes the support plate 1, the mounting plate 5, the travel switch 6, the guide rod 7, the impact sleeve 8, the guide rod sleeve 10, the spring 11, and the locking support 13 And thin nuts 12, the support plate 1 is fixed on the wall 15 by welding nuts 2, bolts 3 and spring washers 4, and the mounting plate 5 is fixed on the support plate 1 by spring washers 4, bolts 3 and welding nuts 2 Above, the mounting plate 5 is provided with a guide rod sleeve 10, a guide rod 7 is provided in the guide rod sleeve 10, the lower end of the guide rod 7 is sleeved with a spring 11, and the lower end of the guide rod 7 is provided with a thin nut 12. The sleeve 8 is fixed on the guide rod 7 by a tightening screw 9. The percussion sleeve 8 includes an upper percussion sleeve 81 and a lower percussion sleeve 82. Both the upper percussion sleeve 81 and the lower percussion sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com