Formulated fracturing fluid of micro emulsion gel

A technology of microemulsion gel and pressure distribution, which is applied in the field of fracturing fluid, can solve the problem of large damage to the permeability of the reservoir and diversion section, large amount of polymer residue and fluid loss, and the problem of the permeability of the reservoir and diversion section. Injury and other problems, to achieve the effect of improving the flowback effect, reducing the polymer content, and improving the sand-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

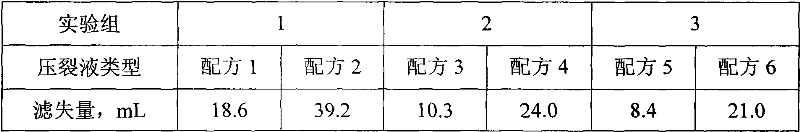

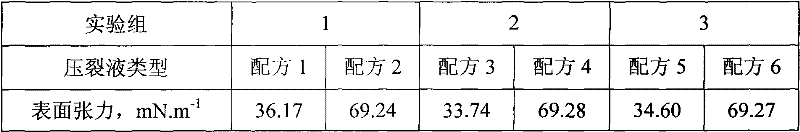

[0017] In the following, 3 groups of fracturing fluids composed of 6 formulations were used to conduct comparative experiments on fluid loss and surface tension. The experimental results are listed in Table 1 and Table 2.

[0018] Formula 1 (microemulsion gel compound fracturing fluid): 3.8% microemulsion system + 0.1% polymer + 0.25% crosslinking agent + 0.05% gel breaker + 0.05% heat stabilizer + 95.75% water;

[0019] Formula 2 (gel fracturing fluid): 0.1% polymer + 0.25% crosslinker + 0.05% breaker + 0.05% heat stabilizer + 99.55% water;

[0020] Formula 3 (microemulsion gel compound fracturing fluid): 10.7% microemulsion system + 0.3% polymer + 0.7% crosslinking agent + 0.3% gel breaker + 0.08% heat stabilizer + 87.92% water;

[0021] Formula 4 (gel fracturing fluid): 0.3% polymer + 0.7% crosslinking agent + 0.3% gel breaker + 0.08% heat stabilizer + 98.62% water;

[0022] Formula 5 (microemulsion gel compound fracturing fluid): 16.7% microemulsion system + 0.5% polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com