Preparation method for instant tea solid particle beverage

A technology of solid granules and instant tea, which is applied in the production of black tea, green tea, black tea, white tea, green tea solid beverage granules, and yellow tea. It can solve the problem of damage to active ingredients and tea quality, loss of catechins, and influence on tea color. , taste and aroma, etc., to achieve the effect of clear and transparent tea soup, low energy consumption and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

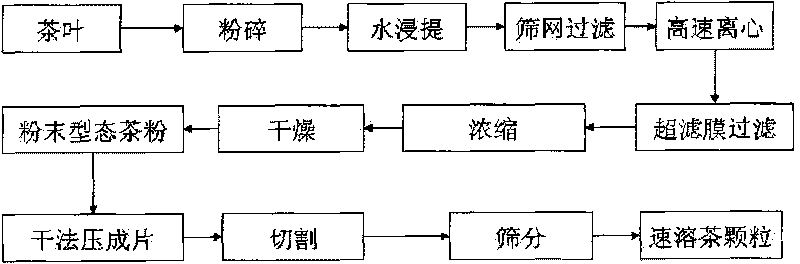

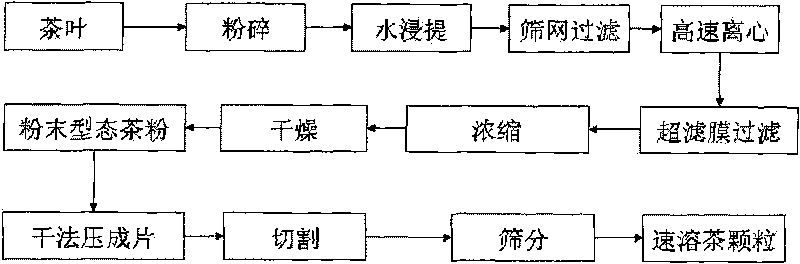

Method used

Image

Examples

Embodiment 1

[0037] a) tea crushing process:

[0038] Pulverize Huangshan Maofeng green tea into 10-80 mesh.

[0039] b) water leaching process:

[0040] Put 200kg of crushed Huangshan Maofeng green tea into a 3-ton dynamic multi-functional extraction tank, add 2000kg of purified water at 45°C, and heat through the jacket with steam, control the extraction temperature at 45-50°C, stir and extract for 30 minutes, and then filter with a sieve , add 1000kg of pure water at 45°C to the filter residue, stir and extract at 45°C for 20 minutes, combine the two filtrates,

[0041] c) Sieve filtration process:

[0042] Filter the combined filtrate.

[0043] d) High-speed centrifugation process:

[0044] The temperature was lowered to 30° C. by circulating water, and the suspended solids were removed by centrifugation in a high-speed centrifuge at a speed of 15,000 rpm.

[0045] e) Ultrafiltration membrane filtration process:

[0046] Filtrate the centrifugate through a PVDF ultrafiltration me...

Embodiment 2

[0058] a) tea crushing process:

[0059] Crush the black tea into 10-80 meshes.

[0060] b) water leaching process:

[0061] Put 200kg of pulverized black tea into a 3-ton dynamic multifunctional extraction tank, add 2kg of vitamin C at the same time (to reduce the oxidation of active ingredients such as catechins in tea), add 2000kg of purified water at 45°C, and heat through the jacket with steam to control The extraction temperature is 45-50°C, stirring and extracting for 30 minutes, then sieve filtration, adding 1000kg of pure water at 45°C to the filter residue, stirring and extracting at 45°C for 20 minutes, and combining the two filtrates.

[0062] c) Sieve filtration process:

[0063] Filter the combined filtrate.

[0064] d) High-speed centrifugation process:

[0065] The temperature was lowered to 30° C. by circulating water, and the suspended solids were removed by centrifugation in a high-speed centrifuge at a speed of 15,000 rpm.

[0066] e) Ultrafiltration mem...

Embodiment 3

[0079] a) tea crushing process:

[0080] Crush the dry black tea (Pu'er tea) into 10-80 mesh.

[0081] b) water leaching process:

[0082] Put 200kg of crushed dry black tea (Puer tea) into a 3-ton dynamic multifunctional extraction tank, add 2000kg of 80°C purified water, and heat it with steam through the jacket, control the extraction temperature at 80°C, stir and extract for 30 minutes, and then sieve Filter, add 1000kg of 80°C pure water to the filter residue, stir and extract at 80°C for 20 minutes, and combine the two filtrates.

[0083] c) Sieve filtration process:

[0084] Filter the combined filtrate.

[0085] d) High-speed centrifugation process:

[0086] The temperature was lowered to 30° C. by circulating water, and the suspended solids were removed by centrifugation in a high-speed centrifuge at a speed of 15,000 rpm.

[0087] e) Ultrafiltration membrane filtration process:

[0088] Filtrate the centrifugate through a PVDF ultrafiltration membrane with a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com