Method for preparing novel ocean lysozyme antibiotic preservative coated film

A technology of lysozyme and antibacterial film, which is applied in the field of preparation of new marine lysozyme antibacterial and fresh-keeping coating film, can solve the problems of poor water vapor barrier ability, limited application, moisture migration hindrance, etc., achieve good shelf life, extend shelf life, The effect of elongation and moisture permeability coefficient increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

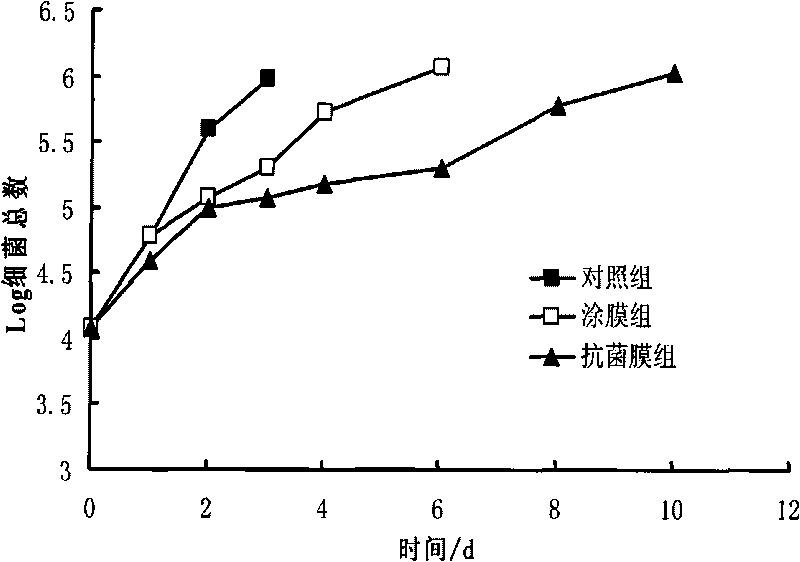

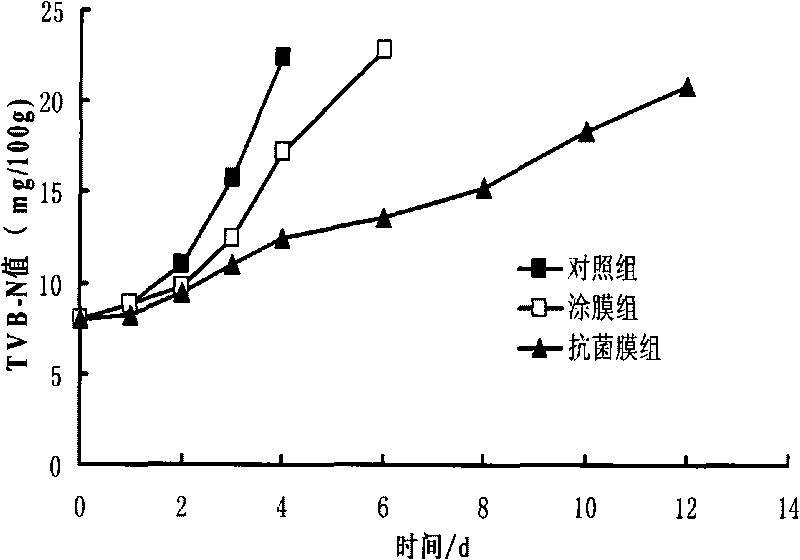

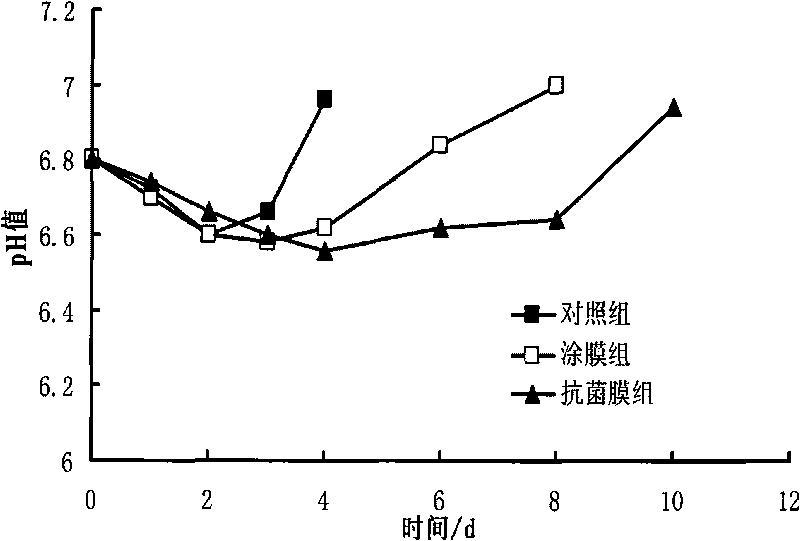

[0083] Dissolve 20 grams of sodium alginate in 976 grams of sterilized water at 50°C and stir at a constant temperature for 2 hours until a viscous liquid is formed, then add 4 grams of glycerin and mix well, then centrifuge at 4000r / min for 15 minutes at a high speed, and the centrifuged liquid is washed at 10°C / 30 Gradient cooling and thickening, the thickened solution is degassed under 0.1MPa vacuum for 1-2 hours to obtain a sodium alginate solution, wherein the concentration of sodium alginate is 20g / L, and the concentration of glycerol is 4g / L. Add 3 grams of marine lysozyme, 1.5 grams of tea polyphenols and 0.8 grams of potassium sorbate to the sodium alginate solution and fully mix to form an antibacterial film solution, then put the antibacterial film solution in 5% by mass CaCl 2 Gel into film in solution. The film is used in the preservation of tilapia fillets to prolong the shelf-life preservation period by about 5.5 days.

Embodiment 2-3

[0085] Embodiment 2-3 preparation step is identical with embodiment 1, is differently listed in the following table:

[0086]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com