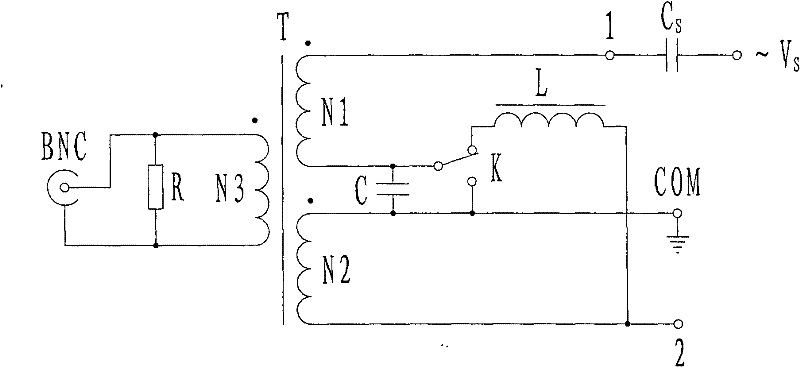

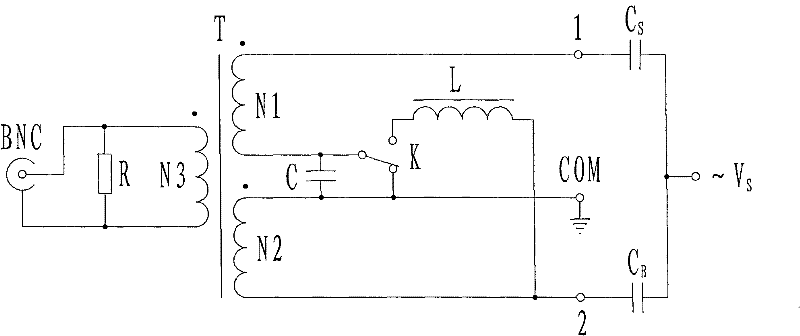

Capacitor partial discharge detection circuit

A partial discharge detection and capacitor technology, applied in the field of detection, can solve problems such as difficult detection, decreased detection sensitivity, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] see figure 2 , in the unbalanced test mode, the unbalanced contact 3 of the test mode switch K is closed, the balanced contact 4 is opened, and the unbalanced input terminal 1 is connected to the capacitor C of the test object S , the balanced input terminal 2 is not connected to the standard capacitor C B , so the test is more convenient. After the test power is turned on, since the inductance L is in a short-circuit state for low-frequency signals and high-impedance for high-frequency signals, while the capacitor C is in a high-impedance state for low-frequency signals and short-circuit for high-frequency signals, the low-frequency test current signal is from The head end of N1 enters and flows out from the end of N1. After passing through the inductor L, it enters from the end of winding N2 and flows out from the head end of N2. The magnetic fields generated in the two windings are completely opposite and cancel each other out; the high-frequency discharge pulse si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com