Test system of spindle-type magnetorheological fluid performance

A technology of magnetorheological fluid and testing system, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as small adjustable range of ratio, complex structure, large consumption of magnetorheological fluid, etc., to achieve reduced sensitivity, The effect of improving system resolution and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

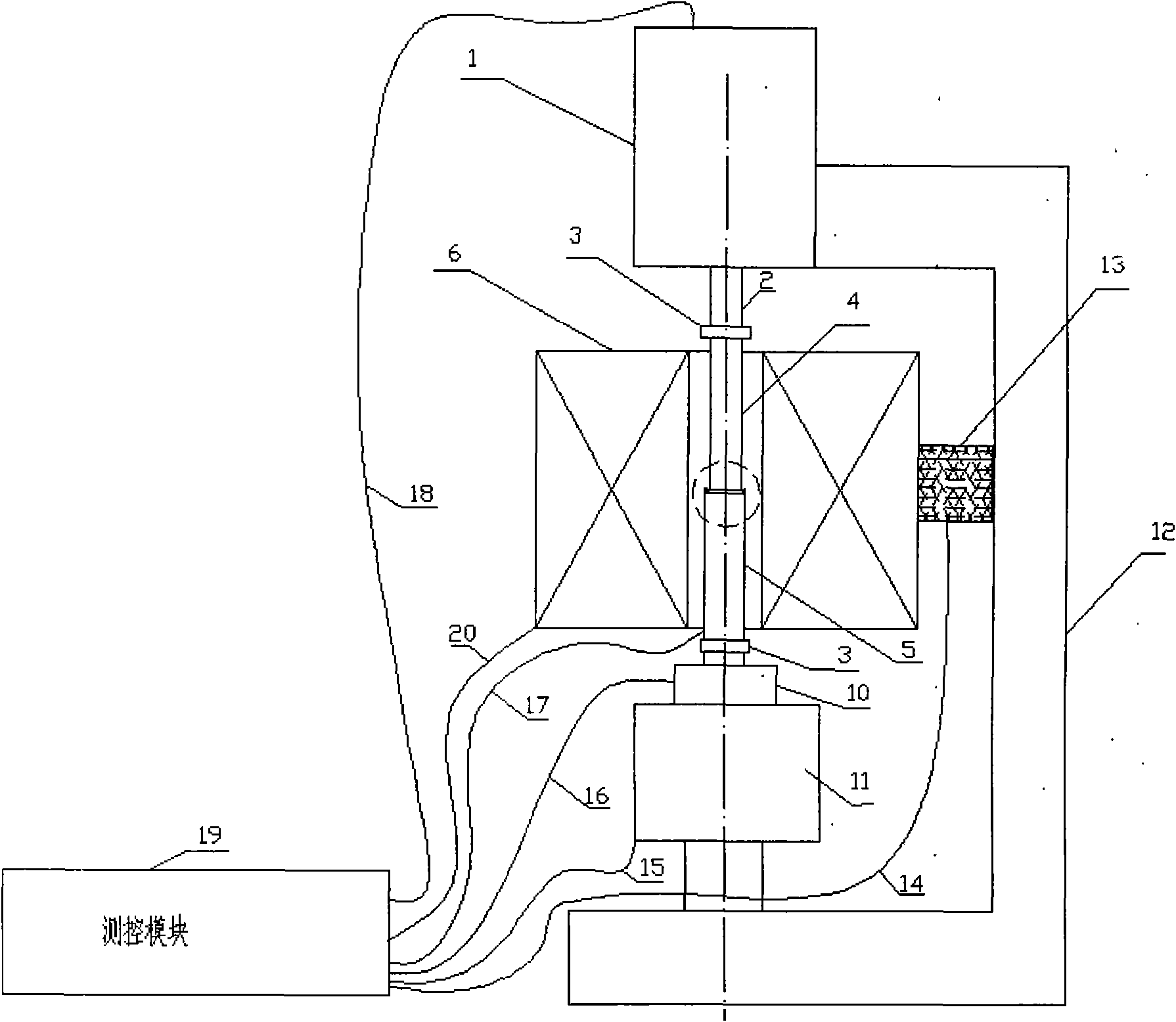

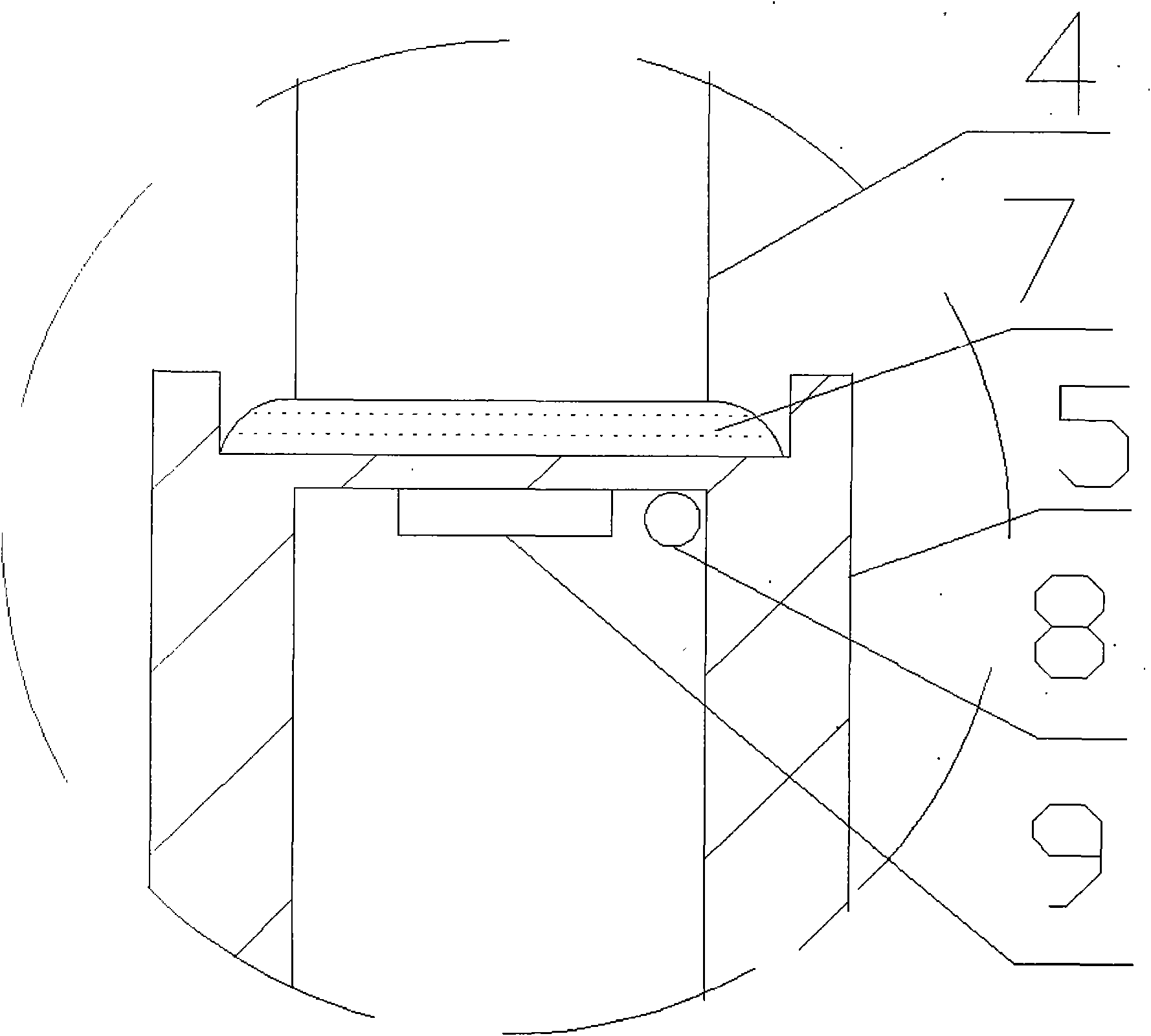

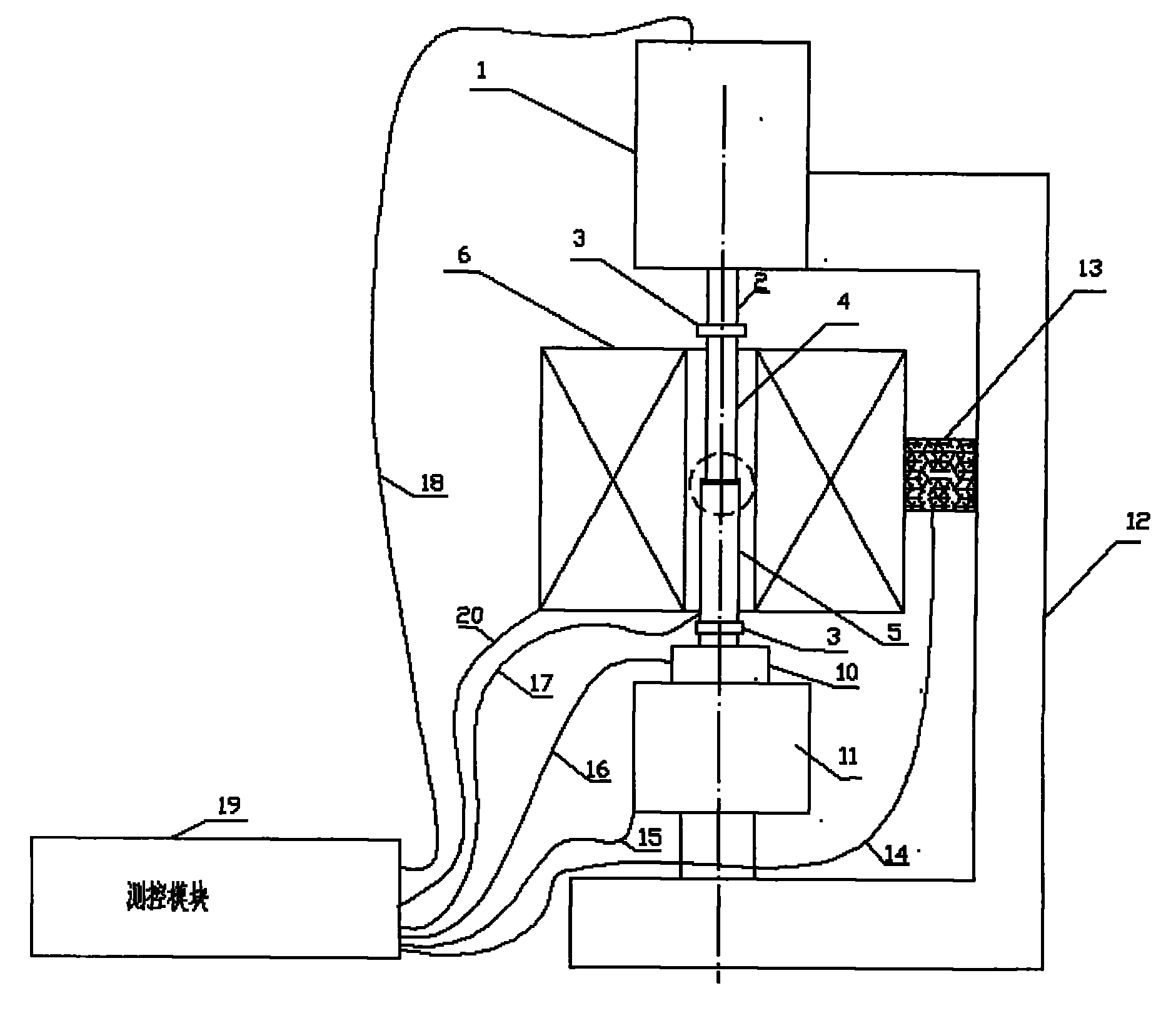

[0016] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0017] figure 1 Among them, the speed-regulating motor installed on the frame 12 and the output transmission shaft 2 of the reducer 1 are connected with the upper shaft 4 through the coupling 3, and the lower shaft 5 is connected with the torque sensor 10 for measuring torque through the coupling 3 The torque sensor 10 is fixed on the precision lifting platform 11, and the hollow solenoid 6 is fixed on the solenoid lifting mechanism 13. The magnetorheological fluid 7 to be tested is placed in the flat-bottomed blind hole at the top of the lower shaft 5, and Placed in the middle of the hollow solenoid 6. The hollow solenoid 6 has a magnetically shielded case. The measurement and control module 19 is connected through the solenoid power line 20, the solenoid lifting mechanism control line 14, the precision lifting platform control line 15, the speed regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com